At the Emerson Exchange conference in Austin, Emerson’s Sean McLeskey presented Fixed Gas and Flame Detection Best Practices. His abstract:

Many industrial processes involve dangerous gases and vapors: flammable, toxic, or both. With the different sensing technologies available, and the wide range of industrial applications that exist, selecting the best sensor and locating them properly for the job at hand can be a challenge. This workshop will help you get a better understanding of application challenges, learn basic installation best practices, and understand the benefits of using flame and gas detection solutions.

Sean opened with a safety case study at a refinery where personnel heard a “pop” and saw what appeared to be steam. It was a gas release that led to people being injured and the refinery being shut down for 3 months with losses in the tens of millions.

Sean opened with a safety case study at a refinery where personnel heard a “pop” and saw what appeared to be steam. It was a gas release that led to people being injured and the refinery being shut down for 3 months with losses in the tens of millions.

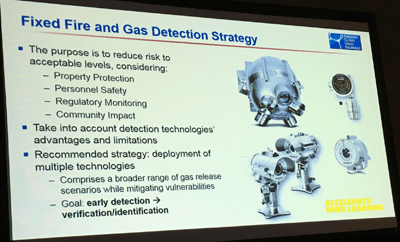

Fixed flame and gas systems are for detecting releases of process hazards and provide time to alert personnel and put the process into a safe state. These systems protect people, property, provide regulatory compliance and maintain good relations in the surrounding community.

Ultrasonic gas leak detection listens for the ultrasonic sound caused by escaping gas. It is not impacted by wind direction that some other detector technology relies upon. It provides first detection but does not provide composition of the gas detected.

Another technology is point gas detection which requires the gas to pass by to be detected by the sensors. This technology is typically applied near leak sources where the escape points, such as gaskets are known. One example technology is catalytic bead combustible gas detection. This technology is used to monitor several targeted gasses across applications including hydrogen.

Infrared sensors are another type of point gas detectors. Their strengths compliment catalytic bead. It is unaffected by high concentrations of hydrocarbon and works in the absence of oxygen, unlike the catalytic bead technology.

Multi-spectrum infrared flame detectors are the highest performing detectors and have excellent immunity to false alarms.

Multi-spectrum infrared flame detectors are the highest performing detectors and have excellent immunity to false alarms.

After performing a risk assessment, installation considerations include pressure of gas source—is it high enough for ultrasonic listening. For the point gas family of technologies gas must be able to reach the sensor. Considerations include the properties of the gas, ambient conditions and obstructions between the gas source and detector, open path technology to cross beam path. Depending on the area where the detectors are located, beams, point gas and ultrasonic listening have advantages and disadvantages.

For flame detectors, the optical sensor is like an eye. Considerations include the size of the area to be monitored, detection technology, obstructions, nature of flame source, and potential blind spots.

No one detector is a silver bullet for use in all applications. Each has their advantages and disadvantages and you will need to consider your application. You can connect and interact with other gas and flame detector experts in the Analytical group in the Emerson Exchange 365 community.