Traditionally, most of the sensors in industrial processes were wired into the control systems or supervisory control and data acquisition (SCADA) systems. Because of the expense of the sensors, junction boxes, cabling/conduit/cable trays/etc. and installation and commissioning time, sensors were usually limited to just what was required for control.

But as process manufacturers and producers try to improve safe operations, production levels, reliability and energy efficiency, more sensing than just what is needed for control is required. Wireless sensors have significantly lowered the barriers to their installation in monitoring and optimizing the process.

And the barriers for getting the information from these additional sensors into the right hands—whether locally on site or to experts anywhere in the world—have been lowered.

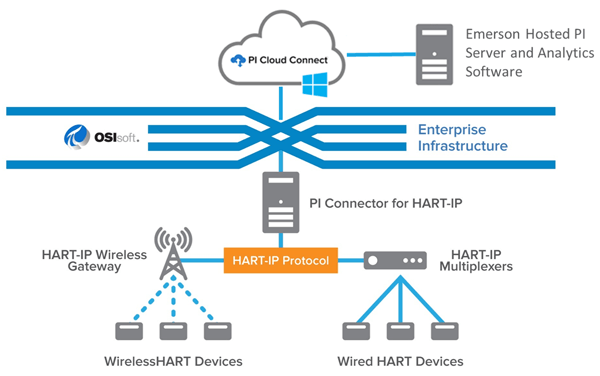

One example was the announcement you may have seen, Emerson and OSIsoft team up to help improve plant operations with OSIsoft’s PI Connector for HART-IP, which streamlines access to HART field device information and feeds it to numerous diagnostic and process optimization tools for the local or remote experts to evaluate and make decisions upon. This is the Industrial Internet of Things (IIoT) in action.

Emerson’s Brian Atkinson demonstrating Advisor applications at Dell EMC World conference

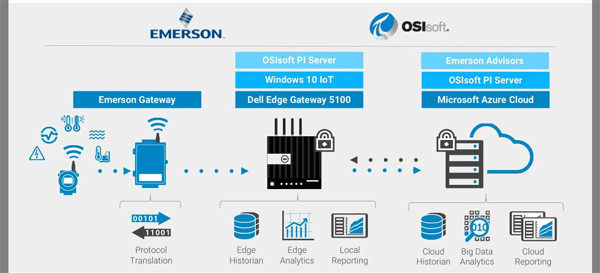

The sensors and final control elements in the production process securely communicates wirelessly with a wireless gateway. Via the HART-IP protocol and PI Connector for HART-IP, the process variable and diagnostic information from the sensors and final control devices are sent to the OSIsoft PI System historian located on a Dell Edge Gateway.

Through the PI Cloud Connect, this historical data connects with a PI System Server located on a Microsoft Azure virtual machine. From anywhere in the world, this data can be accessed on PC-based and mobile apps. We’ve discussed many of these monitoring applications in prior posts such as pump health, heat exchangers, air-cooled heat exchangers, relief valves and steam traps.

Here is a look at the flow of this information from sensor to app for decision maker.

Mike noted that many stakeholders within a production facility can improve their respective areas of responsibilities with these analytical tools. For example, reliability engineers can benefit from improved equipment availability with asset health advisory applications. Process engineers can improve equipment performance with performance advisory applications. And energy managers can improve overall efficiency with energy advisor applications. These advisor apps are integrated with the rich analytics in the advisor applications located out in the cloud.

Each of these applications requires the sensors, historical tracking of process variables and diagnostic information and analytics to turn the data into information on which decisions can be made. The experts making these decisions may be local with the company, remote with the company or with a 3rd-party supplier with appropriate subject matter expertise. Read the 6 steps to increase availability, safety and profitability through remote equipment monitoring solutions brief additional ways to put these technologies and work practices into action.

If you’re not already here to see this in action this week, don’t worry, it will be here next week for the October 24-28 Emerson Exchange conference in the exhibit area. There are also great workshops, roadmaps and other sessions to attend such as: Modernize your plant with IIoT at your own pace, Operational Excellence Enabled by Industrial IoT, Emerson’s New OSI PI Based Equipment Monitoring Platform, Industrial Internet of Things, and more!