I saw a recent news item, Emerson introduces digital, +175°C, high-precision pressure and temperature transmitter designed for corrosive harsh downhole measurements, and wanted to find out more about the application for this technology.

I caught up with Emerson’s Joe Kitzman to learn more. When drilling for oil and gas, downhole pressure and temperature measurements are used:…to improve oil and gas production and solve problems of reservoir engineering… Reservoir temperature is governed primarily by the reservoir’s proximity to the earth’s mantle, and by the relative heat exchange capacities and thermal conductivities of the formations forming the lithostatic sequence that includes the reservoir.

Depending on depth and location, this downhole environment can be quite harsh. This Paine 320-12-0010 Series digital transmitter increases the top-end temperature range from 150°C to 175°C. Pressure ranges up to 30,000 PSIA (2068 BAR).

Depending on depth and location, this downhole environment can be quite harsh. This Paine 320-12-0010 Series digital transmitter increases the top-end temperature range from 150°C to 175°C. Pressure ranges up to 30,000 PSIA (2068 BAR).

Applications for this transmitter include its use in downhole tools, such as measurement while drilling (MWD), logging while drilling (LWD), and Wireline to name a few. Offshore energy exploration, artificial lift and subsea risers, and subsea hydraulic controls are more potential applications.

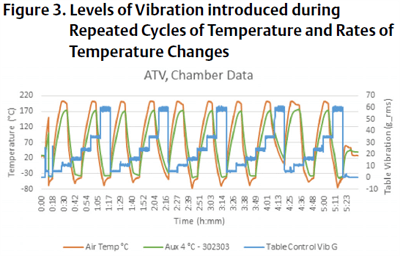

Joe shared that the 150°C version of this transmitter could survive 10,000 hours at this temperature and survive the high shock and vibration of downhole environments. With the introduction of the 175°C version, the design team has qualified it through Highly Accelerated Life Testing (HALT) to meet the high shock and vibration requirements of the downhole tool manufacturers. Field trials were performed to verify the performance in application.

Joe shared that the 150°C version of this transmitter could survive 10,000 hours at this temperature and survive the high shock and vibration of downhole environments. With the introduction of the 175°C version, the design team has qualified it through Highly Accelerated Life Testing (HALT) to meet the high shock and vibration requirements of the downhole tool manufacturers. Field trials were performed to verify the performance in application.

To handle corrosive downhole environments such as hydrogen sulfide-containing fluids, Iconel 718 oxidation and corrosion resistant housing is used in a slim 0.5″ housing. For the toolmakers, this simplifies the design and eliminates the need for additional electronics related to pressure and temperature measurements. Maintenance is simplified, since no calibration is required if the sensor is replaced. The new sensor is dropped in and zeroed.

You can connect and interact with other measurement and oil & gas experts in the Pressure, Temperature and Oil & Gas groups in the Emerson Exchange 365 community.