Typically, you’ll find broadly used production and data management systems at the heart of effective operational excellence programs. These systems help to identify aging plant infrastructure before these assets lead to unplanned shutdowns, slowdowns and quality excursions. Much of the data that feeds these systems comes from the underlying instrumentation and automation systems.

At next week’s Operational Excellence in Refining and Petrochemicals conference in Houston, Texas, Emerson’s Chris Hamlin and Julian Annison will lead a workshop, Automation: Your (not so) secret weapon for achieving operational excellence. Chris and Julian will explore what operational excellence means in a variety of industries and discuss the insights that can be applied to refining and petrochemical businesses.They will engage workshop attendees to share their experiences and understanding of how automation and production information infrastructure can significantly enhance or inhibit performance. From this exploration, Chris, Julian and the attendees will collaboratively identify steps that can be taken to implement a systematic approach to model the value proposition, and then consider how to best secure business leader support.

Often for refiners and petrochemical producers, instrumentation provides just enough data to satisfy the basic control and safety shutdown requirements. In some cases, these measurement devices provide process variables (PVs) and nothing else in the way of diagnostics to help identify potential issues. Wireless technology has advanced to provide missing or stranded data to help improve process safety, reliability and availability.

The display of this information has also advanced from fixed PCs in control rooms to mobile data access by plant personal connected to the secure wireless plant network. This data, combined with advanced analytics software, can spot trends to help personnel identify and fix impending abnormal situations. Combining this enhanced breadth of data, advanced analytics and experts located on premise or remotely, leads to more predictable and efficient operations.

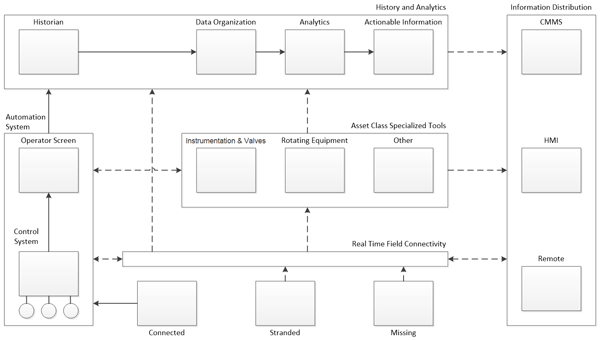

Instrumentation and automation, with their connection to plant assets, provide cornerstones to a distributed information system:

An operational excellence project begins with a detailed look at each of the components in this distributed information system with a series of discovery questions such as:

- Type of control system and historian?

- What would actionable information look like and to whom does it need to go?

- What information is currently missing?

- How is it being done today?

- Who needs to see the information?

- What expertise is missing and who can best provide it?

These questions lead to the development of requirements and a general architecture. They also help to align the cross-functional project participants on a common vision and stack of applications required to implement the vision.

If you’ll be at this conference, make sure to catch Chris and Julian’s workshop. If not, make sure to catch them at the October 24-28 Emerson Exchange conference in Austin or in the Improve & Modernize group in the Emerson Exchange 365 community.