We’ll continue with our series on getting your brownfield automation project approved. In part one, Front End Planning for Control System Modernization Projects, we explored how changes in the project become more expensive the later in the schedule that they are made.

Today we’ll explore the value of modernizing your distributed control system (DCS). Emerson’s Laurie Ben and John Dolenc highlight the importance of a justification methodology and some examples of benefits to help develop the return on investment (ROI) for the business case.Process manufacturers and producers must consider several issues in trying to sustain their operations with an aging control system. Unscheduled downtime can be prolonged if a hardware component fails and takes time to replace due to obsolescence. Expertise on the system may also dwindle as experts retire. As control systems age, they can become no longer cost effective to support.

Compared with modern systems, there is much less flexibility to make changes to support new business opportunities and system capacity may be constrained to support further expansion. Finally, regulatory requirement may drive the need to replace the control system.

Laurie and John described ways to perform a financial analysis on obsolescence failure risk. It starts with looking at the cost of a system shutdown in terms of hardware and labor to repair, the consequences of a process shutdown in terms of clean up and off-spec products, and the value of the lost production to get the process unit back online. The costs and lost opportunities are multiplied by the probability of a system failure. These probabilities can be difficult to determine unless records of the failures have been kept over time with enough data to provide a reasonable confidence interval.

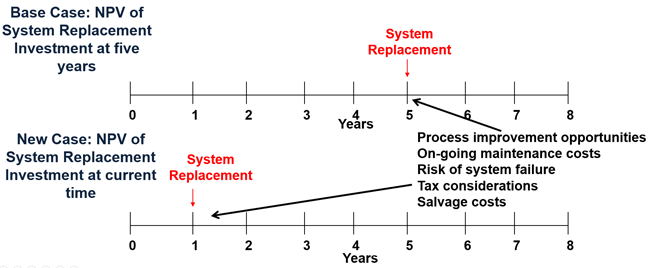

When performing a DCS replacement evaluation, it is important to remember that the base case is not zero capital, since the DCS has a finite life. The base case is the net present value (NPV) of the replacement of the DCS at the end of the current life. The new case is the NPV of system replacement at the current time. The gains in the NPV calculation is the difference in time horizon with estimates for the cash flows from process improvement opportunities, reduction in maintenance costs, risks of system failure, tax considerations and salvage costs of the systems.

Modern systems provide information on when to act to remain at optimum-running conditions. They provide a platform for optimization with their inherent flexibility to easily modify control strategies to improve on the existing control and to meet changing market demands. Operating at the edge of total production capability requires complex and advanced control strategies.

Modern systems are also easier to integrate with other execution and planning systems to foster better collaboration and workflows among cross-functional team members. These collaborative efforts result in improved productivity and profitability for the plant.

In the next post in our series on getting your brownfield project approved, we’ll take a closer look at some ROI-based methods of justification. Until then, you can connect and interact with control system modernization and migration experts in the Improve & Modernize group in the Emerson Exchange 365 community.