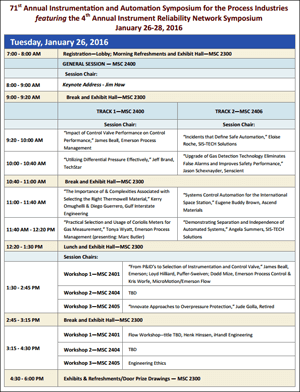

Instrumentation and automation professionals in the oil & gas industries along the Texas Gulf Coast have an excellent resource in the annual Instrumentation and Automation Symposium for the Process Industry. The 71st edition of this 3-day symposium will be held January 26-28 at Texas A&M University in College Station, Texas.

If you’re going, make sure to attend some of Emerson’s James Beall‘s presentations and workshops. James will be presenting “Impact of Control Valve Performance on Control Performance” and co-presenting “From PID’s to Selection of Instrumentation and Control Valves” and “Control Valve Troubleshooting Workshop”.Here is the abstract for the Impact of Control Valve Performance on Control Performance presentation:

Significant amount of time is often spent specifying and selecting the proper control valve for the application. However, this effort is generally focused on the physical properties of the valve such as metallurgy, erosion and corrosion specification, shutoff classification, fugitive emissions requirements, actuator type, positioner type, etc. While these aspects are critical to the performance of a control valve, there are other performance metrics that are vital to the good performance the control loop that manipulates the control valve. These include such metrics such as dead band, resolution, valve gain and step response time. Often poor performance in these areas can significantly reduce the performance of the control loop, sometimes even preventing operation in the automatic mode. The definition and importance of these valve performance metrics will be explained and field examples will be provided.

James will co-present From P&ID’s to Selection of Instrumentation and Control Valve with Emerson’s Dodd Mize & Kris Worfe, and Puffer-Sweiven’s Loyd Hilliard. Here is the abstract:

James will co-present From P&ID’s to Selection of Instrumentation and Control Valve with Emerson’s Dodd Mize & Kris Worfe, and Puffer-Sweiven’s Loyd Hilliard. Here is the abstract:

The Process and Instrumentation Diagram (PI&D) has been issued. Now it is time to select the proper instrumentation and control valves. Are you aware of the various types of instrumentation and technologies that could perform the desired function? For example, level measurement technology includes differential pressure, capacitance, magnetic, float, displacer, ultrasonic, guided wave radar, nuclear and more. What are the characteristics of these technologies and which one would be best for your application? Control valves variations include globe style, rotary, pinch, high performance butterfly, notched ball, balanced, un-balanced, etc. Trim flow coefficient characteristics include linear, quick opening, equal percentage, modified parabolic and others! Control valve positioners are now high performance, microprocessor based devices that have built in diagnostics. This workshop will discuss the technologies of instrumentation for flow, level, pressure, etc. as well as control valves. Then, the selection of the appropriate instruments and control valves based on the P&ID’s will be discussed.

This symposium is not just limited to instrumentation and automation folks here in Texas, so check out the full program to see if it’s something that you might benefit from attending. If you do go, make sure to catch up with James, Dodd, Kris and Lloyd.

You can also connect and interact with other control valve and control performance experts in the Valves and Improve & Modernize groups in the Emerson Exchange 365 community.