Manufacturing capital projects grow ever larger and more complex. At the ARC Industry Forum, ARC’s Dick Hill led a panel, New Approaches to Automation Projects: Reducing Cost and Complexity. This panel included Emerson’s Deston Day who is the director of Perfect Execution. Here was the session description:

New technologies and approaches to project management are making it possible to significantly reduce overall project cost. Smart, configurable I/O, late binding concepts, virtualization, modular approaches, and MAC approaches all have the potential to reduce project cost by as much as 30 percent. Leading end users will discuss these new approaches and share their insights for project success from a range of process industries.

Dick opened up the session defining automation projects as encompassing both greenfield and brownfield sites. New approaches need to take less time, cost less, and be far less complex. A more modular approach to projects are emerging. ExxonMobil’s “It Just Happens” model sought for projects to be: Simple, Capital Efficient, Robust and Timeless. One objective was to reduce the need for specialized technology and knowledge over time.

Wago’s Thomas Holm presented an update of the NAMUR initiative in Europe to reduce the complexity of project execution. Two key aspects are modularization and decentralization. I shared some of the concepts around this initiative in a post, Module-Based Automation in NAMUR NE 148.

Hyonsook Kang next discussed considerations for scoping automation modernization projects. It starts wit getting the right people involved across the organization in the business, on the projects teams and plant personnel. A risk assessment must be done on what it will take to modernize, what it will cost in terms of technology and potential lost production, and what value can a modern control system bring. The top drivers for modernization projects are obsolescence, safety/industry regulations & compliance, and operational excellence.

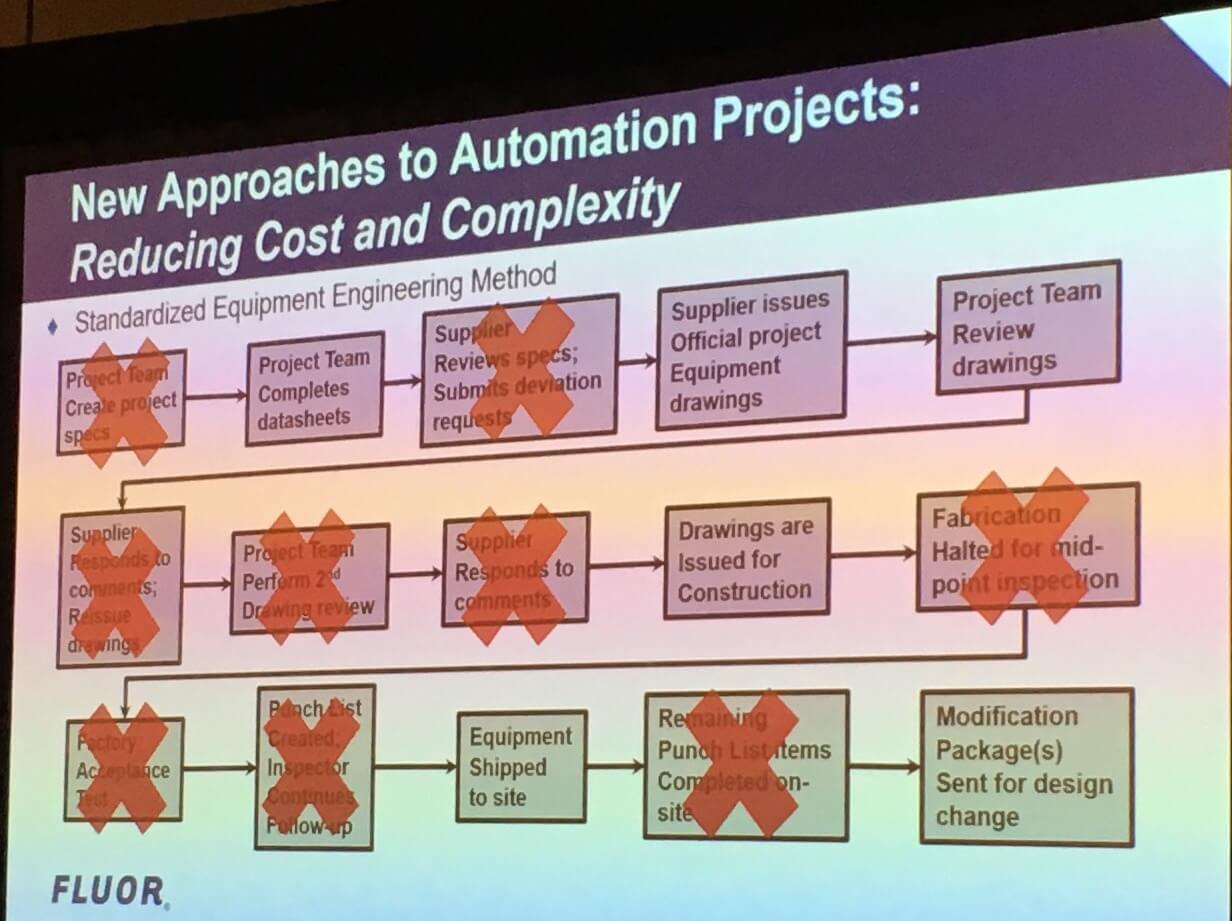

Fluor’s David Hoeppner described the need to change the way projects are executed. Projects are challenged with market pressures, reduced budgets and investor expectations. The traditional project execution method is a very serial process. Each step feeds the next and changes can cause big delays and costs. Working with owners and suppliers, simplification was sought and found:

Fluor worked with Emerson to remove the steps using technologies and work practices. The worked jointly with zero-based requirements to develop new work processes using the DeltaV CHARMS technology. Fluor has measured 4% reduction in engineering manhours. This savings has been seen in traditional “stick-built” projects as well as modular ones.

Fluor worked with Emerson to remove the steps using technologies and work practices. The worked jointly with zero-based requirements to develop new work processes using the DeltaV CHARMS technology. Fluor has measured 4% reduction in engineering manhours. This savings has been seen in traditional “stick-built” projects as well as modular ones.

During the panel portion Deston noted that while the automation technology has been available for a while to reduce project complexity, the change in work practices has not changed to take advantage. He explained that the formation of the people in the project team is important to get right at the front end and make sure they are empowered to execute their role and the collaboration channels are open.

The panelists agreed the early planning is essential especially getting the process data right before paralleling project tasks. They’ll just need to be reworked. Deston describe the importance of communications and cloud-based engineering databases with large projects and global engineering centers. Constant communication between engineering centers is paramount.

Having a trust factor with the project leads is important, especially when the leads are located in various engineering centers. The level of trust needs to be at the level of the team “in the next room”. If quality issues arise the project manager needs to spend more time and perform a root cause analysis.