Gain Flow Measurement Certainty with Gas Flow Meters

Current oil & gas market conditions are putting greater focus on enhancing profitability without acquiring new assets. This has also intensified the tension between cost and risk. Even investments that can optimize costs, minimize losses, or mitigate operational risk are being scrutinized much more diligently today.

Flow measurement is a critical component in measuring for losses and for accurate custody transfer, so there is no doubt that many operators are feeling the urgency to improve fiscal metering data, preserve asset integrity, streamline compliance, and minimize profit loss. But how can metering operators, especially in natural gas transport and trade applications, obtain evidence that flowmeters are “fit-for-purpose” in real-life operational conditions to be able to generate highly accurate flow measurement and cost savings?

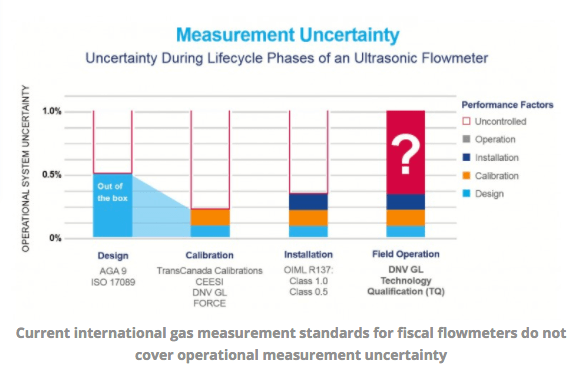

Current international gas measurement standards for fiscal flowmeters focus only on the design and installation of the meters and don’t cover meter performance under field conditions which can change during operation. For instance, AGA and API standards as well as OIML R-137 approval don’t provide conclusive evidence for field robustness and don’t guarantee that fiscal flowmeters will stay within acceptable uncertainty levels under typical real-life operating conditions such as dust, blockage of flow conditioners, buildup on the pipe walls, liquid carry over, etc. unless these meters are removed and sent to a flow lab for recalibration.

To prove and verify the performance of gas flowmeters in the field, DNV GL, a global technical advisor and certification body, developed the industry’s first Technology Qualification (TQ) scheme which is a risk-based assessment that goes a step beyond traditional metrology testing to determine if the metering technology is robust enough to operate under actual field conditions. DNV GL’s TQ puts meter performance claims to the test and provides evidence of the impact of actual operating conditions on meter health and measurement accuracy of gas sales.

In this webinar recording, DNV GL’s Henk Riezebos and Emerson’s Jacob Freeke spotlight measurement uncertainty levels at every stage of a flowmeter lifecycle, including design, calibration, installation, and field operation and explain the benefits of the TQ scheme in controlling a certain portion of operational measurement uncertainty which has not been controlled before, until now.

Henk and Jacob also share the findings of DNV GL’s assessment of two Emerson Daniel gas ultrasonic meter models—the 3415 and 3416 Dual-Configuration Ultrasonic Meters. Each meter model features a redundant design that includes a fiscal (pay) meter with chordal paths and a check meter with reflective paths, all combined in one meter body.

DNV GL’s evaluation proved that this pay-and-check configuration which combines reflective and chordal paths results in the ability to detect operational distortions that chordal— or reflective-path-only ultrasonic meters cannot. The advantage here is that measurement values of the two meters are constantly compared in real time and deviations are detected immediately. The online comparison of two independent measurement principles (chordal and reflective path technologies) help avoid common mode error or effect and provide proof to support extending recalibration intervals.

In summary, DNV GL Technology Qualification for gas flowmeters is a new industry service that provides evidence of the manufacturer’s claims of field robustness and gives end-users confidence that these claims are real. Other benefits of this new TQ include:

- The Qualification can be used for benchmarking the technologies’ ability to mitigate associated risks

- It confirms (or denies) the manufacturer’s accuracy and reliability claims

- It minimizes the risk that real-life metrological distortions can create and the resulting mismeasurement and loss of production

- Operators also now have the necessary evidence to verify field robustness

- The Technology Qualification helps companies better assess potential cost savings

For more insights into DNV GL’s TQ verification process and criteria used to test and determine the metering risk of gas flowmeters, check out the webinar recording.