Electronic circuit boards have historically contained many metal and plastic substances toxic to us, such as lead-based solder. In the decade of the 2000s, the European Union developed the Restriction of Hazardous Substances Directive (RoHS 1) Directive in order to restrict, “…the use of hazardous substances in electrical and electronic equipment…”. Substances banned beginning in 2006 included lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (BPDE). In 2019, this list expands to Bis (2-ethylhexyl) phthalate (DEHP), butyl benzyl phthalate (BBP), dibutyl phthalate (DBP) and diisobutyl phthalate (DIBP).

The reason for this legislation is that if these components are not properly disposed of, they are hazardous to the environment and pollute landfills.

As a manufacturer of automation equipment built with electrical and electronic equipment, much work was required to redesign components to meet these directives. This was important not only for sales into the European Union countries, but also in other countries with similar legislation, including China, Iceland, India, Serbia, Switzerland, Liechtenstein, Norway, Turkey, Taiwan and Vietnam, Ukraine, and Brazil. More countries are adopting these standards or similar ones in the coming years.

I caught up with Emerson’s James McFerrin about the action performed to make the Emerson hardware products in RoHS category 9, Industrial Monitoring and Control Equipment, compliant to the standard to meet the July 2017 compliance deadline for this category. A multi-year effort has been well underway to comply with the regulation for most products. A key objective has been to ensure that product reliability is maintained or enhanced in any redesigns. This effort requires design programs for every product and affects hazardous location approvals and long-term reliability test methods.

This effort required a reworking of much of the hardware components across the major brands including DeltaV, Ovation, AMS, Fisher, Rosemount, Micro Motion, and more. James was involved in the efforts for the DeltaV and Ovation systems which both achieved full RoHS compliance for the hardware components on the list to be made compliant.

Given the breadth of products across the portfolio of Emerson products, the transition to comply started with all in-scope products and potential in-scope applications on portable and handheld equipment will continue over several years for all the products identified to be redesigned.

EU RoHS has Large-Scale Fixed Installation (LSFI) exception where a product does not have to meet the RoHS standards. Typically, a manufacturing facility itself is not LSFI but may contain subsystems that are LSFI. For example, a process unit made with production vessels, piping and instrumentation. The manufacturer determines which areas are covered by exclusions. Some of these LSFI exclusions are explained in a RoHS 2 frequently asked questions whitepaper.

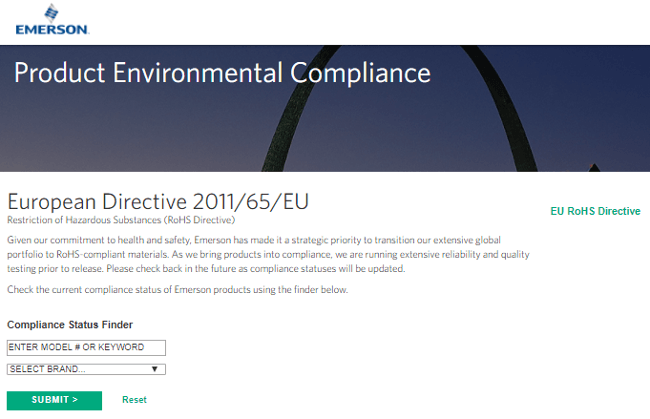

There is a Product Environmental Compliance area on the Emerson.com website that lists the brands and products and where they currently are on the path to compliance with the EU RoHS directive or if they require being applied under one of the exclusions.

Look to this website and contact your local sales office for updates as additional products attain compliance.