At the recent 2018 Gastech Conference in Barcelona, Spain, Emerson’s Patrick Deruytter presented on ways for gas plants and liquefied natural gas (LNG) production facilities to drive operations to top quartile performance.

At the recent 2018 Gastech Conference in Barcelona, Spain, Emerson’s Patrick Deruytter presented on ways for gas plants and liquefied natural gas (LNG) production facilities to drive operations to top quartile performance.

The focus of the presentation was to look at the operational opportunities in the current gas & LNG plants to improve the reliability of the equipment and the process. By improving the current process measurement and control, and analyzing and benchmarking the current operational performance, plant operators gain a better understanding of performance compared to their peers.

Changes in global markets, regulatory environments and rapid technology advancements pose challenges. Existing plants have issues with reliability and operating at optimal performance. The traditional approach to reliability is chasing breakdowns and routine, scheduled maintenance. Also, aging equipment is approaching obsolescence in many cases.

Patrick shared a McKinsey & Company study that projects that data from Internet of Things (IoT) devices will produce insights that drive a potential economic value of $11 trillion by 2025. Given the current state of global manufacturing, there are $ billions of value to be captured in performance improvements. Increasing competition will drive much of the change that drives the realization of this opportunity.

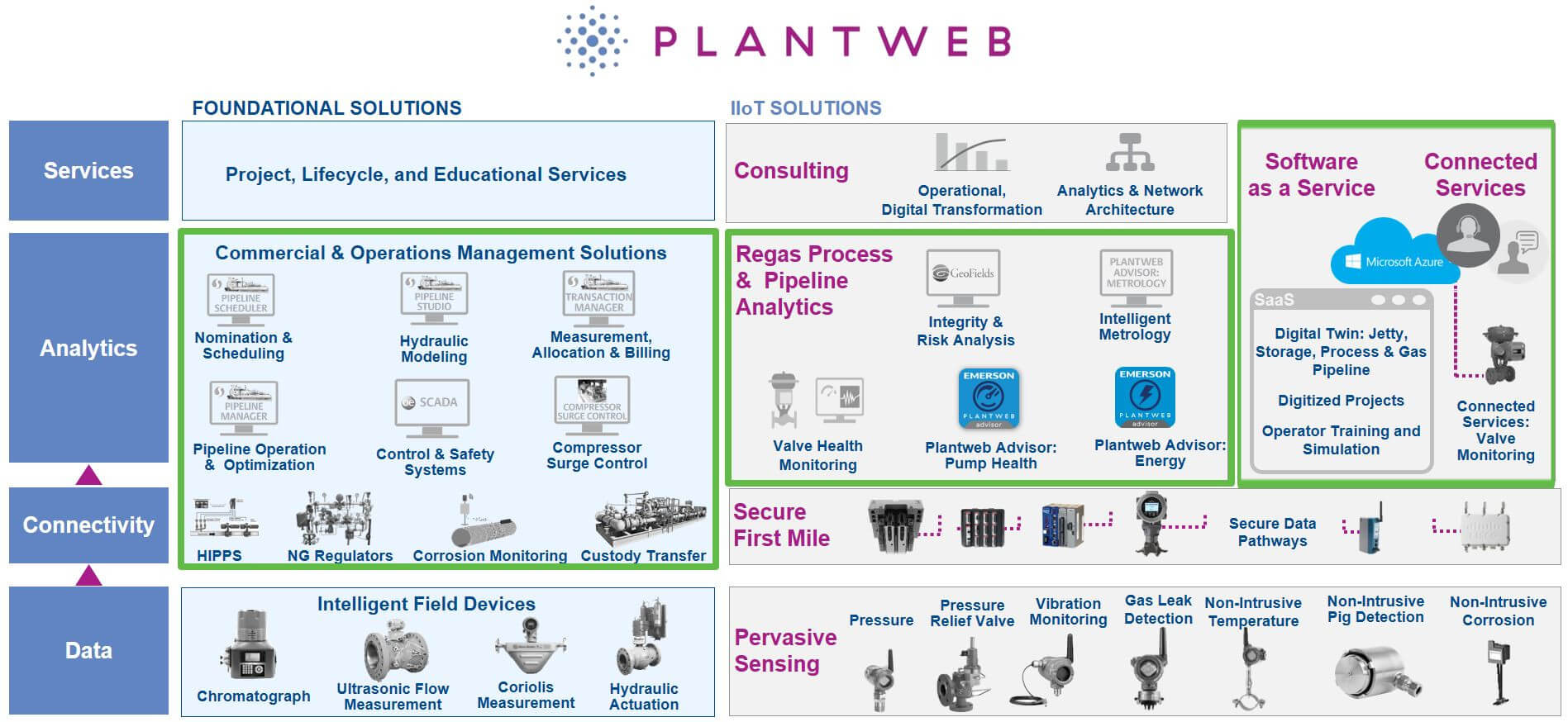

He described the role of technology in this digital transformation to unlock this value. Sensing technologies are rapidly improving and easier to install. Connectivity which bridges data and experts is becoming more cost effective. And, analytical methods and advanced computing provides the way to transform this mass of data into understandable and actionable information. The five areas of rapid automation advancement are in data, connectivity, analytics, collaborative expertise and mobility—to increase the pace of issue or opportunity to improved performance.

He shared an example of the components of this automation architecture would be applied to LNG regasification processes.

Technology alone does not deliver top quartile performance. It’s important to make sure the actionable information gets delivered to the right people at the right time so that it can be acted upon. Work practices must be re-examined, and a culture established that fosters collaboration.

Patrick shared some of the automation technologies that enable this collaboration including Plantweb Insight—lightweight analytics-based applications with pre-configured algorithms for specific asset classes, Plantweb Advisor—enterprise-wide analytics for plant, unit and equipment health analytics, real-time corrosion monitoring, and additional sensors applied pervasively for improving reliability, energy efficiency, safety & compliance.

These technologies bring the data and analytics to the expert to facility instant escalation and preempt breakdown/shutdown conditions. Cloud technologies bring this collaboration together and enable supplier experts to provide Connected Services.

Patrick shared a story of how a major LNG producer avoided a plant shutdown by having Emerson experts, through Valve Connected Services, identify an issue on a critical valve in time to avoid a plant shutdown, saving more than $1 million. The other benefit is that this LNG producers has reduced unnecessary preventive maintenance activities by instead relying on the experts watching and analyzing the diagnostics.

Performance improvements come from better insights than is possible with current practices. These technologies provide new ways to collaborate and be more productive.

Visit the Plantweb digital ecosystem area of Emerson.com for more on the technologies and practice to drive toward top quartile performance. You can also connect and interact with industry and technology experts in the Oil & Gas and IIoT & Digital Transformation groups in the Emerson Exchange 365 community.