In a whitepaper, Application of Density Meters to Liquid Hydrocarbon Measurement, Emerson’s Dean Minehart highlights passages from the American Petroleum Institute (API) Manual of Petroleum Measurement Standards (MPMS) that give guidance on online density meter selection/operation, sampling system design and field proving methods.

He opens noting:

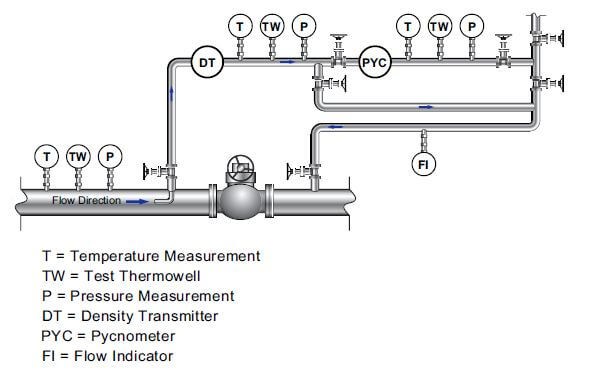

Continuous density measurement may be accomplished with a device located in the main flowing stream or in a slipstream. Density measurement is utilized in both volumetric and mass measurement systems. Volumetric measurement requires the use of density to determine correction factors for temperature and pressure on a flowing liquid. Inferred mass measurement systems require density measurement at meter conditions to determine mass flow. Direct mass measurement systems require online density measurement at a meter prover to determine prover mass and calculate a mass meter factor.

The application will determine the selection of the right density meter to use.

Density uncertainty requirements for inferred mass measurement system applications is lower than volumetric measurement system applications. This is due to a fact that in inferred mass measurement a density term multiplies by volume to calculate mass. Density is used in volumetric applications with flowing temperature & pressure to compute a combined correction factor that corrects indicated volume to standard conditions.

Dean references API MPMS Chapter 9 Section 4: Manual of Petroleum Measurement Standards Chapter 9 – Density Determination – Section 4 – Continuous Density Measurement Under Dynamic (Flowing) Conditions about installation guidance:

Density meters may be installed upstream or downstream of a volumetric flow meter. The recommended installation is downstream of an inferred mass volumetric flow meter.

This API document also provides guidance on field proving density meters with pycnometers or hydrometers. The new proving guidance (API MPMS Chapter 14 Section 6) for pycnometers is three consecutive runs with +/- 0.05% repeatability. For hydrometers, the guidance (API MPMS Chapter 9 Section 4):

…allows for the use of either a batch proportional composite sample or spot sample. Liquid applications following this proving guidance must be stable at atmospheric pressure and measured volumetrically (e.g. crude oil or refined products).

Dean shows the calculations for density measurements in Net Standard Volume (NSV) measurement systems, direct mass measurement systems, inferred mass measurement systems, and inferred mass provers.

Read the whitepaper for the details of these calculations and how to successfully apply inline density measurements. There is an online tool to help you size and select the right density meter for your application.

You can also connect and interact with other flow, density and viscosity measurement experts in the Flow group of the Emerson Exchange 365 community.