Many technologies are available to measure flow. Electromagnetic flow meters, also known as magnetic flow meters or magmeters, are well suited for a variety of applications across a range of industries including pulp and paper, metals and mining, water and wastewater, food and beverage, chemical and petrochemical and oil and gas. Because the magnetic flow meter design does not leave any protrusions or obstructions in the pipe, they are able to accommodate an array of applications from clean and sanitary liquids to slurries and highly corrosive or abrasive fluids.

Many technologies are available to measure flow. Electromagnetic flow meters, also known as magnetic flow meters or magmeters, are well suited for a variety of applications across a range of industries including pulp and paper, metals and mining, water and wastewater, food and beverage, chemical and petrochemical and oil and gas. Because the magnetic flow meter design does not leave any protrusions or obstructions in the pipe, they are able to accommodate an array of applications from clean and sanitary liquids to slurries and highly corrosive or abrasive fluids.

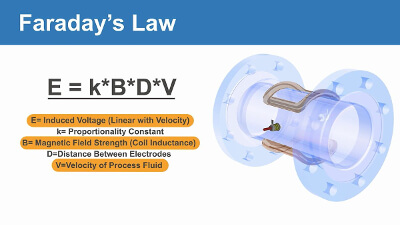

This flow measurement device consists of a sensor and a transmitter. The sensor is placed inline and measures an induced voltage generated by the fluid as it flows through a pipe. This induced voltage, based on Faraday’s law of induction, is mathematically defined as E=k*B*D*V – induced voltage (E) which is directly proportional (k) to the velocity (V) of the fluid moving through the magnetic field (B).

The transmitter part of the magmeter converts this voltage into a quantifiable flow velocity. The volumetric flow rate of the fluid is calculated using this known velocity along with the area of the pipe.

The transmitter can also provide a user interface to read the flow values as well as perform diagnostic and calibration functions. In this 2+ minute YouTube video, Rosemount 8712EM – Wall Mount Magnetic Flow Meter Transmitter, Emerson’s Scott Dudek describes how this wall-mount transmitter helps to address flow challenges and provide troubleshooting assistance.In the video, Scott explains how the transmitter enables smart meter verification (SMV), which provides a complete, on-line verification of device performance. This verification saves significant expense by reducing labor and outsourced calibration service costs while eliminating process interruption. The SMV test verifies calibration and the complete health of the sensor, electronics, and analog loop. It measures key performance indicators, such as deviations from prior tests, as well as uses a baseline signature that is then compared to the factory baseline. This verification helps maintain measurement accuracy and meter integrity, which reduces costs through early detection of potential issues.

Watch the video to see the intuitive transmitter user interface, diagnostics for sensor coating alerts, and use in combination with AMS Device Manager or ProLink software for traceability required for compliance reporting. For more, visit the magnetic flowmeter section of Emerson.com.

You can also connect and interact with other flow measurement experts in the Flow group of the Emerson Exchange 365 community.