One only has to do cursory “people-watching” to see how connected most all of us are to our mobile devices. Whether it’s social feeds, news, messaging or other activities much of our attention goes there. This technology is transforming the way we interact, learn and perform tasks.

For manufacturers, these transformation is extending into their production processes. In a Control Engineering article, Five essential criteria for effective mobile HMIs, Emerson’s Mariana Dionisio, Camilo Fadul and Cindy Scott highlight the strategies that should be considered for bringing human machine interfaces (HMIs) to a smart phone or tablet device.

They open the article:

Placing process control information on mobile devices for engineers, operators, managers, or maintenance technicians is becoming a necessity to enable digital transformation and elevate the performance, productivity, and safety of facility operations. Creating an effective mobile strategy is critical to the success of projects and operations because it helps balance the need for flexible access to operations technology (OT) information with information technology (IT) safety and security requirements.

The 5 criteria include:

- Native integration

- Remote operator stations

- HTML5 mobile-ready HMI

- Mobile applications

- Always consider total cost of ownership

I’ll recap ideas from two of these criteria and invite you to read the article for the rest. Native integration leads to:

…less engineering work because the process control systems and mobile technologies are designed to share and securely transfer information without requiring duplication of the system configuration.

It also means that the IT organization can manage interoperability, security, network ports and other common elements with the IT network infrastructure.

An HTML5 mobile ready HMI provides:

…display portability and ease of use to a facility’s HMI plan by showing control room displays on a web browser. This enables personnel to see the same data and graphics securely as operators in a facility remotely, which can help ease collaboration between control room personnel and by remote personnel.

From a security standpoint:

…mobile access to operations data can be limited to read-only, with cybersecurity built-in, by enforcing strict user permissions or ensuring only authorized personnel can access specific data depending on role and other factors such as location. Additionally, access from mobile devices can be limited to connectivity from business networks that are isolated from the control network by firewalls.

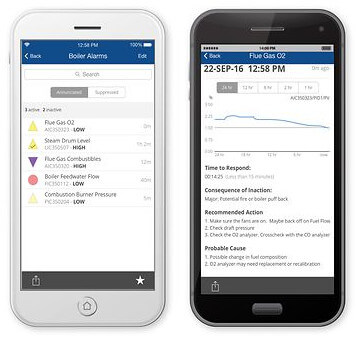

Read the article for Mariana, Camilo and Cindy’s thoughts on criteria for remote operator stations, mobile applications and consideration of total cost of ownership. DeltaV Mobile incorporates these criteria to streamline workflows by making it easier for managers and engineers to share critical information for better decisions and improved operations.

You can connect and interact with other DeltaV experts in the DeltaV group in the Emerson Exchange 365 community or face to face at the October 1-5, 2018 Emerson Exchange conference in San Antonio, Texas.