Some key ways simulation technology is used by manufacturers and producers for training, optimizing operating procedures and engineering to evaluate ways to improve overall performance. In a 2019 Ovation Users’ Group Conference presentation, Ovation Digital Twin Technology – Embedded Simulation Update & New Applications, Emerson’s James Thompson and Shen Zhang provides an overview of Digital Twin technology, how it integrates with the control system, and the role of cloud-based Digital Twin applications.

Some key ways simulation technology is used by manufacturers and producers for training, optimizing operating procedures and engineering to evaluate ways to improve overall performance. In a 2019 Ovation Users’ Group Conference presentation, Ovation Digital Twin Technology – Embedded Simulation Update & New Applications, Emerson’s James Thompson and Shen Zhang provides an overview of Digital Twin technology, how it integrates with the control system, and the role of cloud-based Digital Twin applications.

They opened comparing the actual running process to a simulation. Plant models emulate the dynamic responses of the plant itself. Virtual controllers in the simulation act like real controllers and I/O and the operator interface software performs emulated hard station control in the simulation.

They defined elements in the Ovation Digital Twin technology. These include a large library of high-fidelity algorithms based on first principles, process models created with standard Ovation application tools, complex flow-network solver ’embedded’ within Ovation virtual controllers, and management and updates performed within the Ovation environment. Together these provide familiarity amongst the plant staff with hardware and application tools.

The simulator tools are networked together and connected to the live Ovation system through an Ovation Switch. The Simulator runs in a VMWare virtualization environment for both the operating system and Ovation software environment. This configuration decreases hardware footprint, reduces hardware maintenance, improves collaboration and efficiency of engineering and development, simplifies expansion over time, and allows for rapid & efficient management of systems.

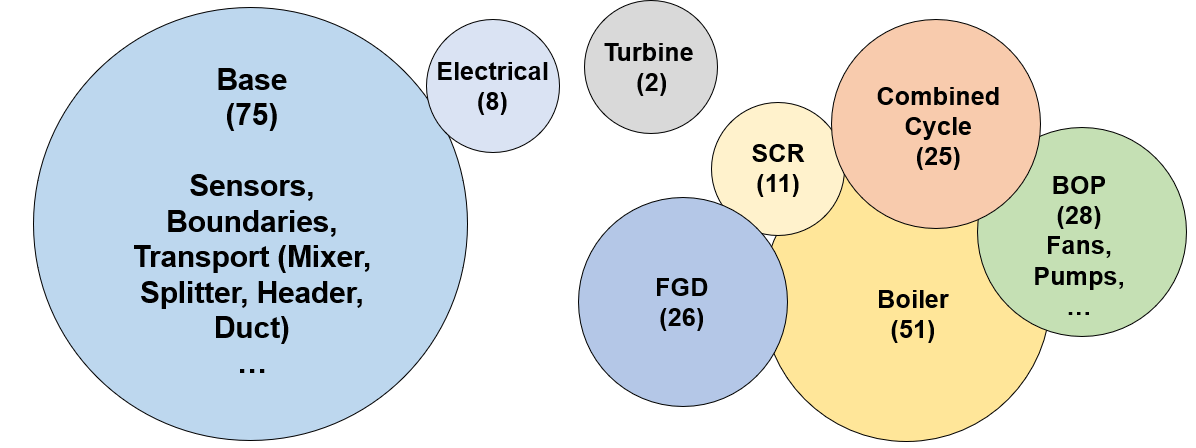

The high-fidelity simulation model algorithm library includes 180 unique model algorithms in 8 areas—electrical, turbine, flue gas desulfurization (FGD), selective catalytic reduction (SCR), combined cycle, boiler, balance of plant (fans, pumps, etc.), and base models (sensors, boundaries, mixers, splitters, headers, ducts, etc.) Some models are in multiple suites. These models adhere to the ANSI/ISA 77.20 Fossil Fuel Power Plant Simulators: Functional Requirements standard.

Simulation fidelity can range from simple tie-back simulations that provide basic visual/functional feedback only up to a complete high-fidelity physical model governed by first principles physics.

From a simulation maintenance perspective, the intended usage of the simulation should drive the areas to focus actions. The simulation should be maintained at least once per year. If the simulation is being used for root cause analysis, then it’s important that the model is up to date with the live process. If the main use is to optimize controls on the live control system, then it’s important that the live DCS and virtual DCS are synchronized. And, if the main use of the simulation is for operator training, maintenance activities should ensure that the degree of realism is not lost.

Cloud-based digital twin solutions offer several advantages over locally-hosted simulations. Asset availability is generally higher, and the user experience is a full Windows experience through remote desktop protocol. Footprint is minimized, and maintenance of hardware and software is simplified.

Shen described live digital twin improves upon offline simulators and separate simulations from the live process in that the digital twin has direct access to the live plant DCS. The plant data and configuration can used to recalibrate the model for higher fidelity, generate additional data that’s difficult to obtain for prognostic tools, and synchronize the simulation to provide immediate relevant training. Full scale adoption must address regulatory and cybersecurity concerns.

Visit the Power Plant Simulators section on Emerson.com for more on digital twin and embedded simulation technology.