Hybrid industries manufacturers having a combination of process manufacturing and discrete manufacturing, as well as discrete industries manufacturers, require pneumatic controls in their machine automation. A critical component in reliable pneumatic control are filters, regulators, and lubricators (FRLs).

In a Machine Design article, The 6 Things Engineers Should Know About Pneumatic Filters, Regulators, and Lubricators, Emerson’s Jeff Disbrow provides a 101 overview of FRLs and key considerations for reliable operations.

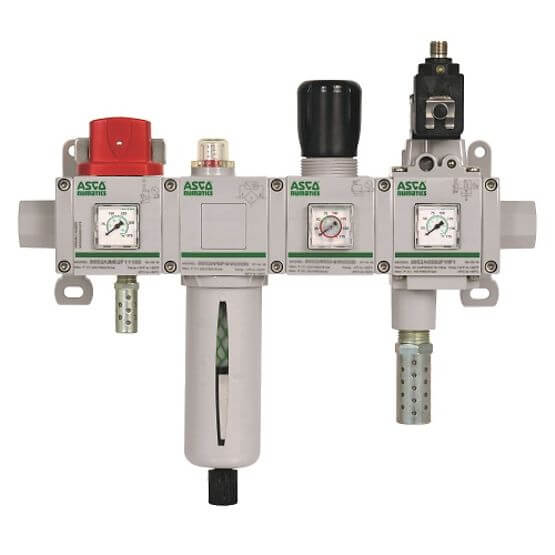

FRLs, such as the ASCO Numatics 651/652/653 series, provide the air preparation for the:

…valves, manifolds, cylinders, and actuators that control machine motion…

As the Industrial Internet of Things technologies are incorporated into FRLs, these devices can measure:

…critical variables such as flow, contamination, and pressure—using the information for further data analytics and decision making.

Jeff breaks down each of these components for those of us less familiar with the operation of pneumatic systems. FRLs are found:

…upstream from the directional control valves, manifold, cylinders, and actuators. Virtually every pneumatic device requires some type of air preparation and pressure control.

The filter, downstream from the shutoff valve:

…is the first component in the air line; then the regulator; and finally, the lubricator…

It is designed to:

…remove oil, particulates, water, and odors from the compressed air.

Regulators:

…set the incoming air pressure to the desired level for the cylinders and actuators operating machinery. Because pressure in the plant’s air drops frequently and varies, consistent pressure regulation is essential to ensure appropriate machine reaction times and speeds.

Lubricators:

…are installed to introduce small amounts of clean oil into the air stream. The oil cleans and protects downstream components from wear and corrosion.

Jeff’s six key considerations include:

- The operating environment

- Proper pressure specification

- Lubrication

- Shutdown valves

- Correct air flow

- Filter replacement

Read the article for more on each of these six key considerations and the increasing role of IIoT in providing the data to analytics software to spot and correct problems early before they impact production.

Visit the Air Preparation section on Emerson.com for more on these filter, regulators and lubricators solutions for packaging, automotive and other demanding application.