Author: Chip Bremer

At Tuesday’s Offshore Technology Conference (OTC) Technical Session “Digitalization Deployed: Case Studies,” Emerson Automation Solutions’ Chief Technology Officer Peter Zornio provided insight on how digital transformation can “close the loop” in areas such as energy optimization, reliability and safety in the oil and gas industry.

At Tuesday’s Offshore Technology Conference (OTC) Technical Session “Digitalization Deployed: Case Studies,” Emerson Automation Solutions’ Chief Technology Officer Peter Zornio provided insight on how digital transformation can “close the loop” in areas such as energy optimization, reliability and safety in the oil and gas industry.

In his presentation, Zornio examined the benefits of secure digitalization across these areas and discussed a real-world example of how it can be accomplished by transforming maintenance practices through remote asset monitoring and cloud-based connectivity, leveraging the power of the Industrial Internet of Things (IIoT).

The case study detailed how Chevron partnered with Emerson and Microsoft to save millions of dollars a year in operational costs by implementing a predictive reliability and maintenance program through an IIoT-based solution of instrumenting and monitoring heat exchangers in one of its refineries.

According to the presentation abstract:

Heat exchangers are critical to oil and gas refinery operations due to their ability to recover and transfer heat input, and most refineries operate anywhere from 200-400 of these units per facility. However, because they are rarely instrumented well enough to allow for adequate insight into their health and performance, these pieces of equipment can also represent a major source of inefficiency, process downtime and maintenance expense.

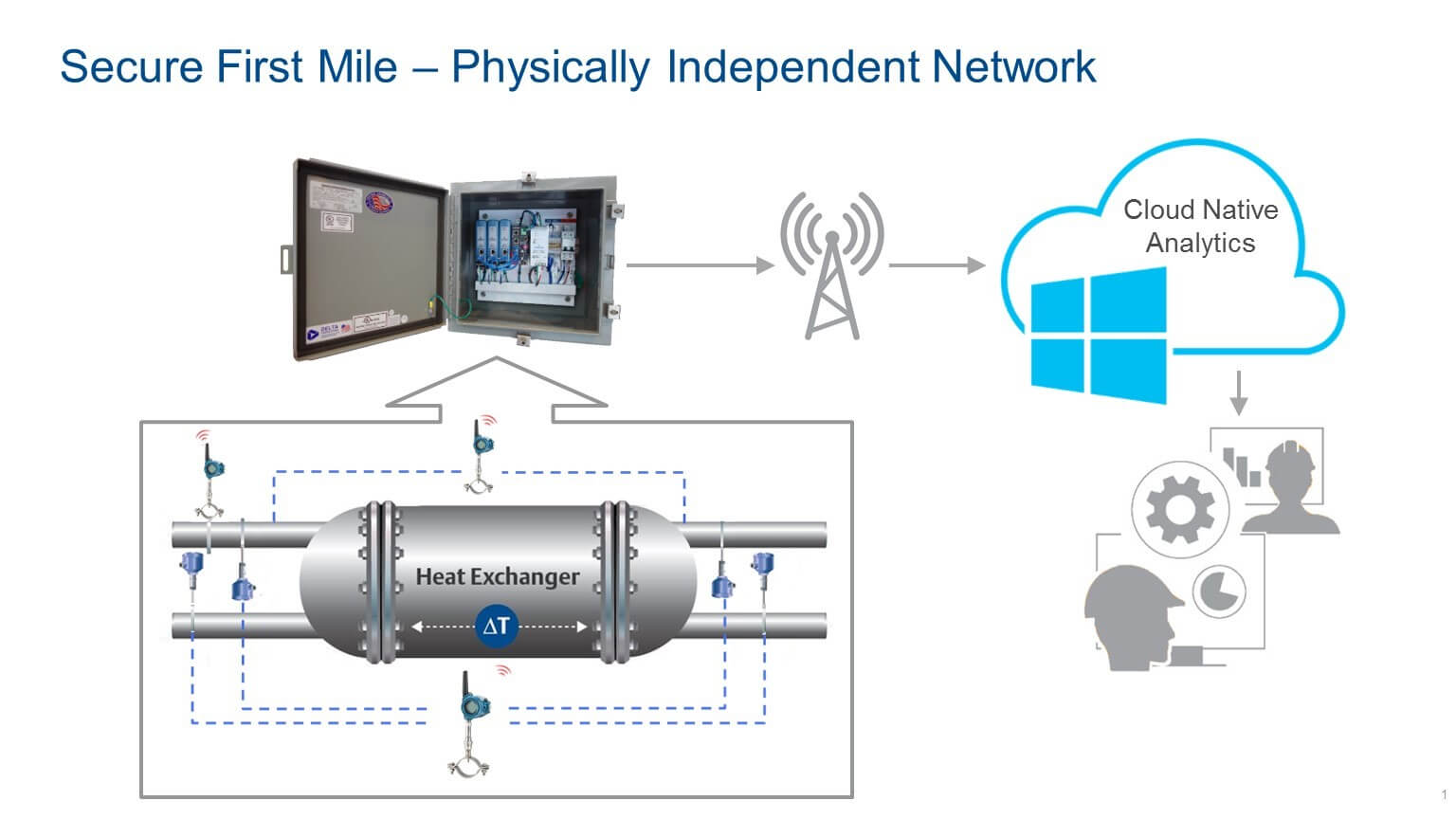

To implement this solution, Chevron worked with Emerson to design a unique wireless sensor network based upon reliable and accurate surface-sensing technology that clamps directly onto the heat exchanger piping. By avoiding installation process penetration, the sensor network provided a cost-effective measurement alternative that also eliminates potential leak points common with other temperature sensors.

The company also worked with Emerson to design a physically-independent, wireless architecture to transmit heat exchanger data safely and securely to a Microsoft Azure cloud-based platform where it could be analyzed for optimized maintenance activities.

The network was designed to operate separately from the company’s existing network infrastructure to not only ensure rapid data exchange but also avoid any security concerns of connecting through Chevron’s critical operational control networks.

Chevron then selected an IIoT-based asset monitoring service that provides remote analytic support by using pre-configured algorithms to interpret the heat exchanger data and generating long-term trending reports with actionable recommendations.

Said Zornio:

We were able to move them from a preventive mode of reliability to an actual predictive condition-based maintenance strategy. By getting the data securely uploaded to the analytic model in the cloud, the results were available to everyone, including the maintenance personnel on the ground who could look at it from a phone or any mobile device.

The company’s physically-independent wireless architecture was designed to ensure fast and secure data exchange without occupying operational control networks to connect to the cloud-based analytic support.

According to Zornio, the project provided a strong enough return on investment for the company to justify expanding to multiple sites, which could result in hundreds of millions of dollars per year in savings on operational costs. Also, due to its scalability, the solution could be extended to other critical assets, such as pumps and cooling towers.

Said Zornio:

For many energy companies, finding a comprehensive solution that offers the advantages of remote monitoring and cloud-based connectivity is not difficult. It simply requires the right business case and technology partnerships.

This program shows that by integrating a cloud-based platform with a complete digital ecosystem in an environment as operationally complex as an oil and gas refinery, we can deliver a true predictive maintenance model that can result in reduced downtime, more efficient maintenance practices and continued safe operation across the entire enterprise.

Visit the Emerson at OTC 2019 section on Emerson.com for more information on Emerson’s activity at the 2019 Offshore Technology Conference.

From Jim: You can also connect and interact with other oil & gas experts in the Oil & Gas group in the Emerson Exchange 365 community.