We see digital transformations all around us in our daily lives—music, streaming movies and shows, transportation, etc. But what about in our world of manufacturing and production that relies on the tried and true?

Many initiatives are underway as pilots and successes are being achieved. In a Chemical Processing article, 10 Steps to Jumpstart Your Digital Transformation, Emerson’s Will Goetz outlines key steps to help drive business performance improvements in these initiatives.

Will opens highlighting some of the business drivers for digital transformation initiatives:

Will opens highlighting some of the business drivers for digital transformation initiatives:

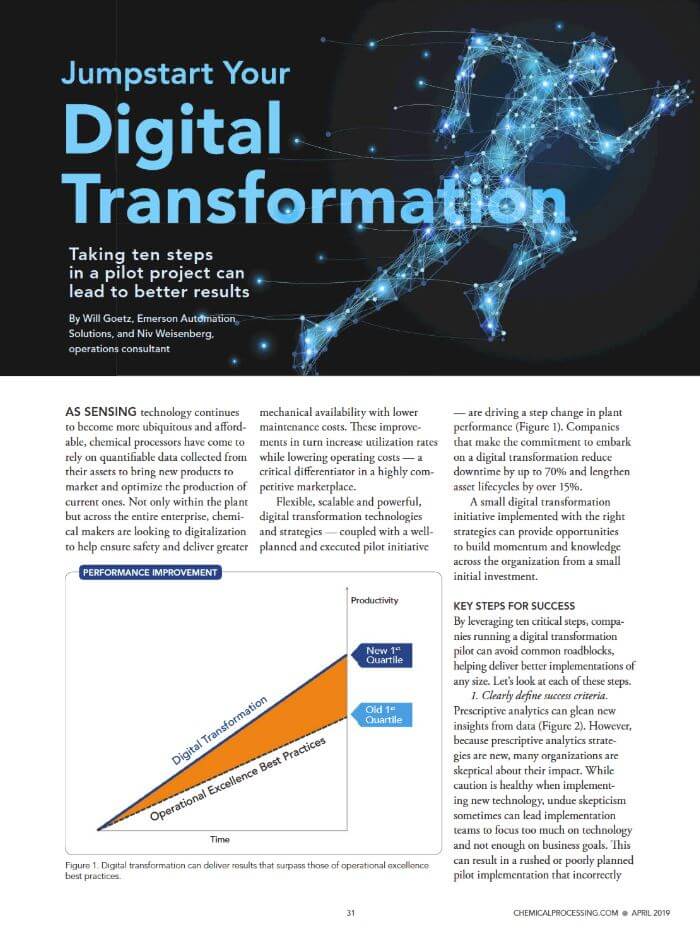

…chemical makers are looking to digitalization to help ensure safety and deliver greater mechanical availability with lower maintenance costs. These improvements in turn increase utilization rates while lowering operating costs…

The payoff?

Companies that make the commitment to embark on a digital transformation reduce downtime by up to 70% and lengthen asset lifecycles by over 15%.

He notes that by starting small and having the right strategies, that these efforts can deliver success and momentum on which to build. Here are Will’s ten critical steps for success:

- Clearly define success criteria

- Understand current systems and solutions

- Identify relevant stakeholders

- Redefine workflows

- Design a solutions architecture

- Chart the path

- Start adopting new technology

- Deploy, operate and test they system

- Drive adoption

- Plan to scale up

I’ll share his first critical step and invite you to read the article for the rest. On clearly defining success criteria:

Prescriptive analytics can glean new insights from data… However, because prescriptive analytics strategies are new, many organizations are skeptical about their impact. While caution is healthy when implementing new technology, undue skepticism sometimes can lead implementation teams to focus too much on technology and not enough on business goals. This can result in a rushed or poorly planned pilot implementation that incorrectly confirms a company’s worst fears and creates the mistaken conclusion it isn’t ready for digital transformation.

Operations leadership can navigate around this potential pitfall by understanding key performance indicator (KPI) goals and using those goals to drive decisions on pilot implementation. A gap analysis allows a company to see opportunities for improvement. These opportunities then drive business goals, helping teams create pilot projects with return-on-investment (ROI) impacts that are easy to quantify and demonstrate.

If your organization is seeking greater business performance in reliability or other strategic areas such as safety & security, energy & emissions, and production, this is an article well worth reading.

Will and the Operational Certainty Consultants can help you chart a roadmap for in your digital transformation efforts for Top Quartile business performance. Learn more in the Operational Certainty section on Emerson.com. You can also connect and interact with other performance improvement experts in the Services group in the Emerson Exchange 365 community.

Update: Toptal has a nice article on how digital transformation initiatives succeed that may be worth a read.