One unfortunate side effect of instrumentation becoming smarter and being able to communicate more data back to the control system, was the increased chance of flooding the operators with too much information in abnormal conditions. Work on the ANSI/ISA 18.2-2016 Management of Alarm Systems for the Process Industries standard began in 2003 to identify and codify solutions to this alarm flood challenge. The IEC 62682 standard is an extension of the ANSI/ISA 18.2 standard and incorporates elements from other alarm management initiatives such as EEMUA 191.

…specifies general principles and processes for the lifecycle management of alarm systems based on programmable electronic controller and computer-based human-machine interface (HMI) technology for facilities in the process industries. It covers all alarms presented to the operator through the control system, which includes alarms from basic process control systems, annunciator panels, packaged systems (e.g., fire and gas systems, and emergency response systems), and safety instrumented systems.

I caught up with Emerson’s Darwin Logerot about the role technology and expertise play in meeting the clearly defined metrics for effectively managing alarms. Much like safety and cybersecurity, the entire lifecycle of alarm management is addressed. This lifecycle includes the definition of alarm system objectives, work processes, and standards, assessing the current state of the alarm strategy in the control systems, and rationalizing these alarms.

After documenting the objectives, work processes and standards for the alarms in a solid Alarm Philosophy, a facility can then embark on the tasks of identification and rationalization. Results of rationalization are then configured in the control system.

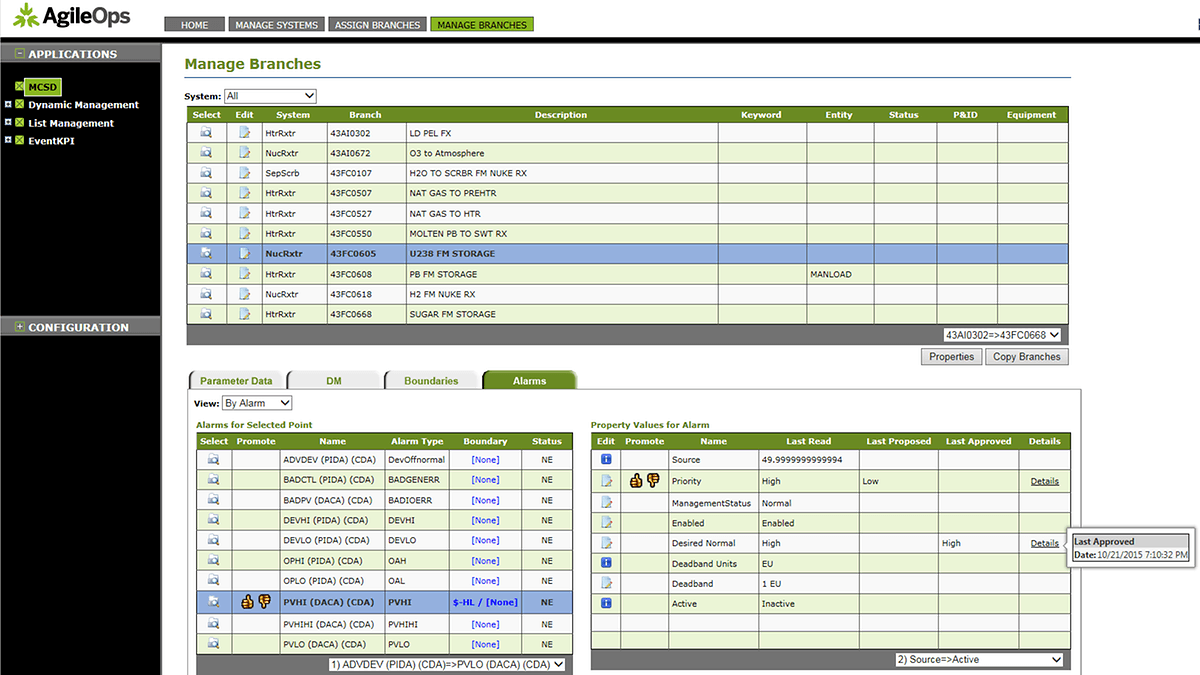

Emerson offers the AgileOps alarm management software suite to aid in the rationalization effort. For alarm system performance assessment, Emerson offers DeltaV Analyze for DeltaV distributed control systems and EventKPI in the AgileOps suite for the DeltaV DCS and other control systems.

Emerson offers the AgileOps alarm management software suite to aid in the rationalization effort. For alarm system performance assessment, Emerson offers DeltaV Analyze for DeltaV distributed control systems and EventKPI in the AgileOps suite for the DeltaV DCS and other control systems.

Darwin explained that manufacturers and producers who work with Emerson alarm management service consultants can use a Dynamic Pre-Rationalization process to reduce the manufacturer’s traditional alarm rationalization efforts by up to 60% to achieve the ISA 18.2 metrics. In the pre-rationalization process, Emerson’s experts perform a first pass rationalization, including dynamic (state-based) alarming recommendations.

Having the rationalization data pre-populated makes the review process with the customer much faster than the traditional approach. Using dynamic alarm management is necessary for a facility to achieve a key ISA 18.2 metric, in that operators should not be presented more than 10 alarms in 10 minutes. Exceeding this value is defined as an alarm flood.

Managing boundaries, which are the limits in which the process should always operate, should also be understood, documented and managed by the respective boundary owners in engineering, operations, maintenance, and health, safety & environmental organizations. Technologies such as the AgileOps software can help manufacturers and producers through their boundary management lifecycle.

Visit the Alarm Management section on Emerson.com to learn more about successfully navigating your way through the alarm management lifecycle. You can also connect and interact with other alarm management experts in the Services group in the Emerson Exchange 365 community.