In a Paper360 magazine article, “Wireless Sensors Improve Toxic Gas Mitigation in P&P Mills”, Emerson’s Forrest Francis explains how workers can avoid nasty surprises.

TV shows add drama saying their stories are “ripped from the headlines,” meaning they’re based on real-world people and events. Sometimes the same thing can happen with articles. The real-world story in this case was a report from Australia about two maintenance workers in a paper mill losing their lives due to hydrogen sulfide exposure. Apparently, they were checking valves on a tank that had unexpectedly filled with the toxic gas and got a fatal dose. With sufficient concentration, you can be incapacitated in seconds and death follows quickly. Additionally, 18 other workers in the plant were taken to the hospital.

This story was one of the things prompting me to write an article for Paper360 in their May/Jun 2020 issue. It’s designed to remind people that paper mills can be more dangerous than we might expect with a variety of toxic products in addition to hydrogen sulfide.

Whether using a sulfite or kraft pulping processes, sulfur compounds are involved. Sulfur dioxide and hydrogen sulfide, among other toxic gases, are common effluents. Hydrogen sulfide is recognized as a very dangerous byproduct and has been the cause of numerous fatalities in the larger process industry sector. Others are sulfur dioxide, chlorine, chlorine dioxide, and methyl alcohol. Because of the risk associated with acute exposure to these chemicals, anyone working in this environment must be aware of where dangers lurk and take appropriate precautions.

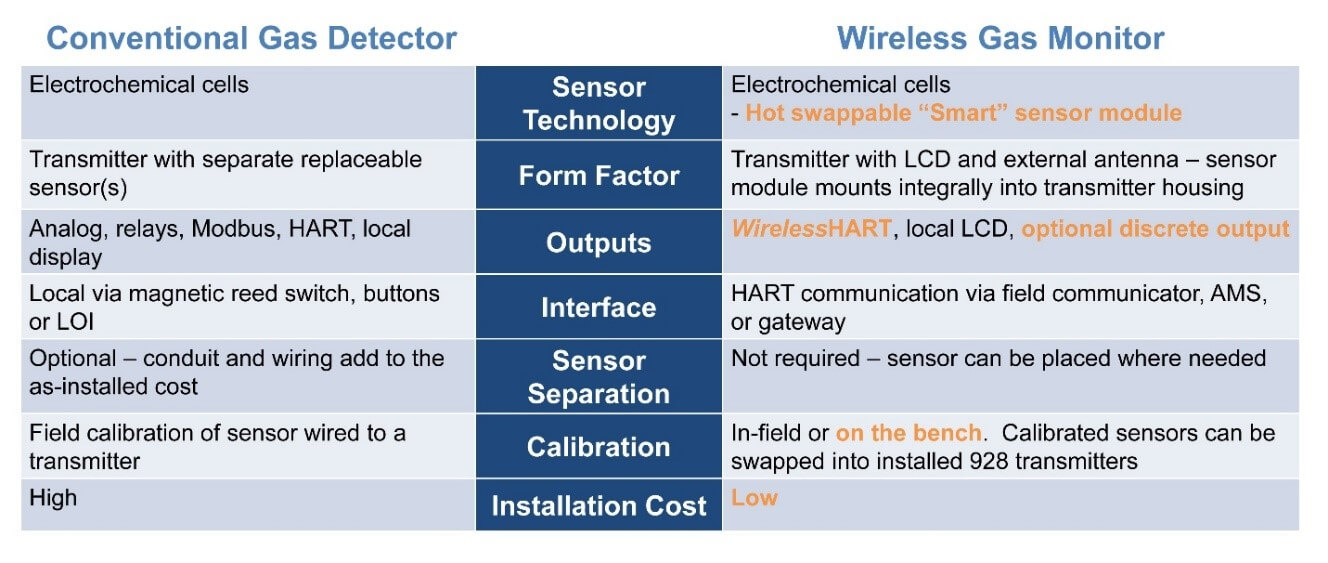

One of the most critical precautions a plant can implement is deploying gas monitors in strategic areas to warn of a gas leak in progress, before a worker can smell it or succumb to it. A primary example is Emerson’s Rosemount 928 Wireless Gas Monitor, which can be configured to measure one of several target gases, including hydrogen sulfide. This wireless toxic gas monitoring system enhances worker safety through early gas leak detection, simply integrates with WirelessHART technology, and eliminates the need for expensive wiring.

Now it is much easier and far less expensive to deploy gas monitors which could very easily save some lives. How well is your plant covered? Is it possible that someone might get an unfortunate surprise from opening the wrong door or climbing down into a pit to check a pump?

Visit the Gas Leak Detectors and Sensors pages at Emerson.com for more on technologies and solutions for flammable and toxic gases. You can also connect and interact with other engineers in the Pulp & Paper Group at the Emerson Exchange 365 community.