Pneumatic technology is widely used in discrete and hybrid manufacturing processes for the machinery used in production and packaging. In a Pneumatic Tips article, Pneumatics: the go-to for food and beverage processing, Emerson’s Amit Patil describes how Industrial Internet of Things (IIoT) technologies have advance pneumatic controls for safer, more reliable operations.

Pneumatic technology is widely used in discrete and hybrid manufacturing processes for the machinery used in production and packaging. In a Pneumatic Tips article, Pneumatics: the go-to for food and beverage processing, Emerson’s Amit Patil describes how Industrial Internet of Things (IIoT) technologies have advance pneumatic controls for safer, more reliable operations.

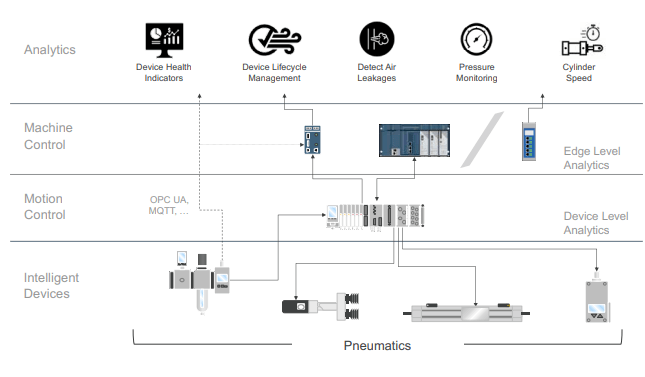

Amit opens notes that with IIoT:

…processing equipment can be safer to operate and predictive maintenance can be enhanced. Plus, energy use can be monitored and controlled more closely.

IIoT sensors in pneumatic devices can measure:

…key operating parameters, like temperature, pressure, flow rates, cycle times, valve response rate and more. Using this information, designers can monitor machine performance more closely than ever before.

With this wealth of additional data, edge devices such the AVENTICS smart pneumatics monitor is an edge gateway device that captures:

…data from machine components and analyze it at the local factory level, comparing the performance to design parameters.

This local processing of IIoT sensor data enable the edge device to send:

…alerts to the appropriate people. And only the outlier data is forwarded to the central control or the cloud.

Amit shares an energy efficiency example where maintenance technicians:

…could determine that a shock absorber on the end of an actuator is deteriorating, just by sensing an increase in cycle speed, even by a few milliseconds. Or machine builders could take advantage of the diagnostic features of IIoT-enhanced pneumatics to measure critical parameters like cylinder velocity.

A safety-related example is a safety light curtain controlling a valve which is being monitored for response time. With:

…IIoT capability, that decline in the valve response time (and the corresponding alert response time) would be captured, analyzed and reported in time for corrective action — before any deterioration in functionality that would put the machine operator at risk.

Read the article for other examples where IIoT-based monitoring can improve energy use, spot leaks and improve cleanliness, reliability, cost and personnel training. Visit the Fluid Control & Pneumatics section on Emerson.com for more on the technologies and solutions to help improve overall safety, reliability and efficiency in your operations.