Emerson’s Matthew Nylund presents on ways to improve product quality with better leak detection at the Emerson Exchange Americas Virtual Series. Here’s his presentation abstract:

Emerson’s Matthew Nylund presents on ways to improve product quality with better leak detection at the Emerson Exchange Americas Virtual Series. Here’s his presentation abstract:

Emerson’s new Quantum Cascade Laser based analyzer provides high speed leak detection on each and every product that comes down the line. Learn how this in-line technology can be used to drive process improvements, leading to decreased customer complaints, reduced scrap, increased efficiency, and data driven continuous improvement.

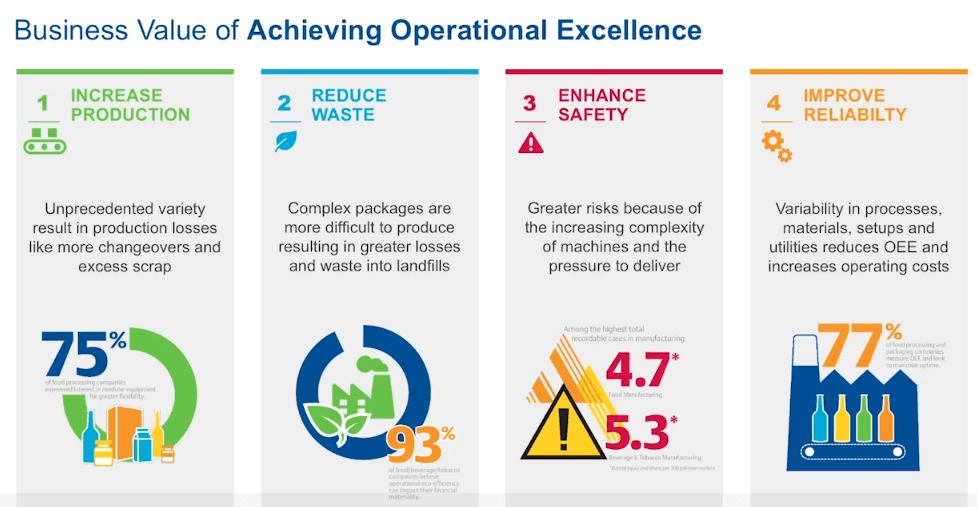

Matthew opened presenting the business value in improving leak detection.

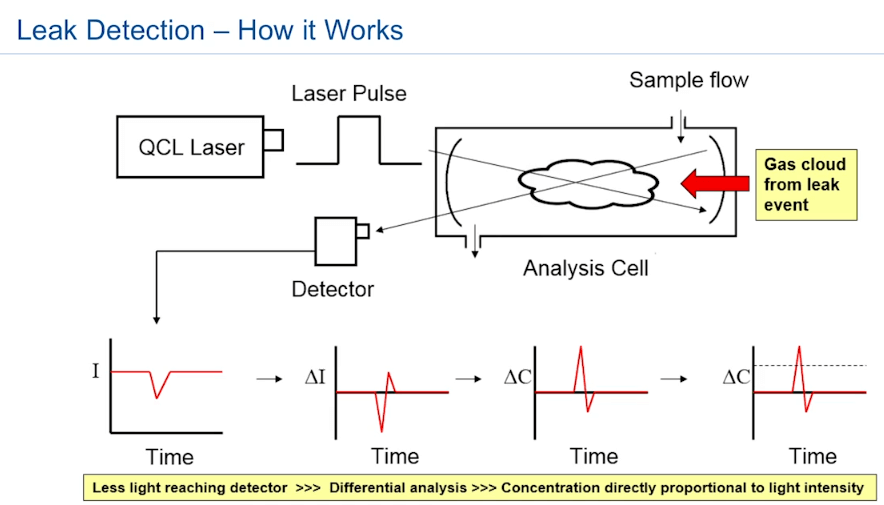

Here’s how the Rosemount CT4215 Packaging Leak Detection System works in packaging sealing applications.

Matthew demonstrated baseline conditions running many food packages through the leak detector. Once the baseline readings were established, he created small punctures in the package. The leak detector showed spikes in air leaking from the package indicating that the seal had been breached. Packaging machines running at high speeds can use the leak detector to identify faulty seals that affect food quality.

Visit the Rosemount CT4215 Packaging Leak Detection System page on Emerson.com for more on how this technology can help you meet your food quality performance standards.