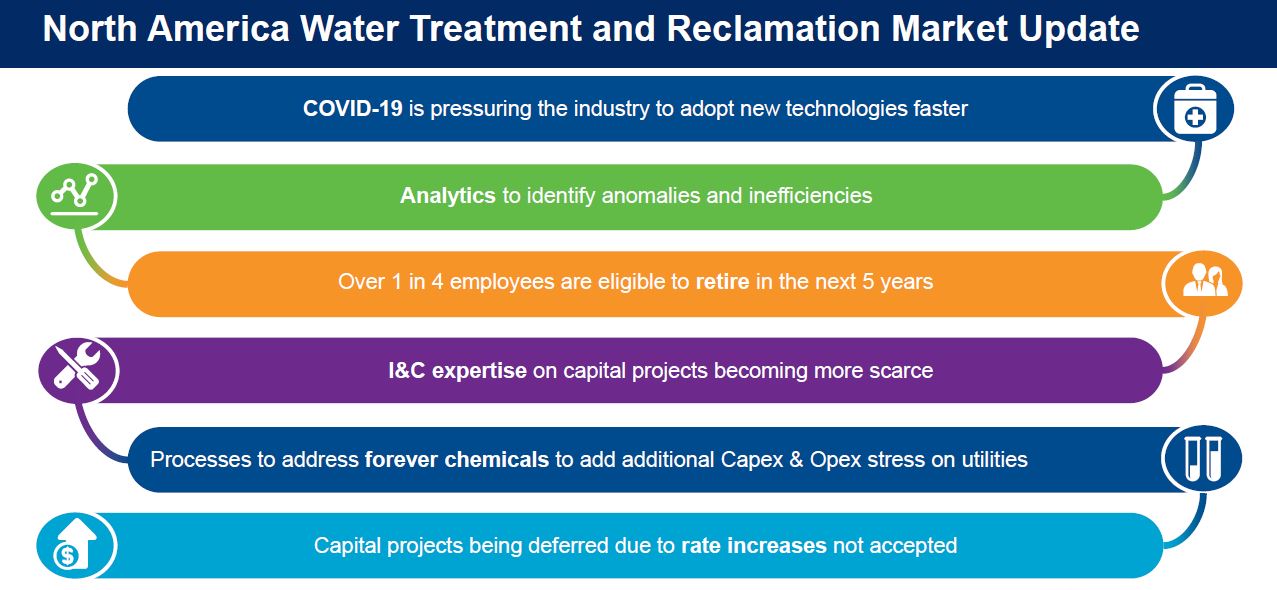

A key topic on the mind of attendees at Emerson’s 2020 Ovation™ Users’ Group Conference water/wastewater industry panel was how technology can help with the influx of new challenges facing water management plants. The COVID-19 pandemic has provided a glimpse of the many challenges organizations must overcome as they continue to reliably provide clean water no matter what is happening in the world.

Using technology to bridge the personnel gap

As organizations have developed strategies to operate with reduced staffing and limited access to the plant, they are turning their attention to ways of leveraging everything they have learned during the pandemic to better prepare for the future. Peter Gabor, Emerson’s water automation solutions business development manager, explained

Limited site access makes critical procedures such as walkdowns more difficult. People on site have learned to be the eyes and ears for personnel who are off site.

One major development to come from this change is a renewed focus on instrumentation. Where once a plant could leave assets without instrumentation because personnel could monitor them during rounds, we now see that plants can easily be forced to operate with a skeleton crew—with little warning—and technology such as sensors play a critical role in maintaining normalcy when plant conditions change.

But even if no future events cause plants to run with reduced crews, approximately 1 in 4 plant employees is eligible to retire in the next five years. When those personnel leave, they often take decades of experience with them. Pete explains,

That is a ton of experience walking out the door, and we need to capture it before the newer employees in the plant have to learn it all over again.

One area in which this loss of experience is felt most heavily is in data analysis. Many experienced operators and technicians can look closely at data and use their decades of experience to see trends and patterns that reveal health and performance issues essential to operation—a skill that takes decades for new employees to learn.

Fortunately, new tools are emerging to help plant personnel make sense of the vast amounts of critical data they collect.

We are building bridges between silos of data. The Ovation automation platform brings data from disparate systems together to help users establish patterns and identify critical data points that are often imperceptible to a person poring over data sheets.

Operators are using these tools to help bring context to their data and turn data points into actionable information to increase performance and operational reliability. To illustrate, Pete shared a preview of one of Emerson’s upcoming analytics tools, which can develop a predictive model of equipment that plant personnel can compare to live data to thoroughly evaluate how plant assets are running.

Staying ahead of the cybersecurity curve

Cybersecure operations keep plants, personnel, and the public safe, and the regulations that require cybersecurity consideration for water/wastewater facilities aren’t suspended when plants are required to run with a skeleton crew.

Dianne McMaster, manager of water automation solutions business development at Emerson, shared strategies for identifying needs and protecting plants while working within a budget and spanning the multitude of platforms operating at a site.

One key strategy is to take advantage of available resources for assessment, such as the AWWA Cybersecurity Assessment Tool. Dianne recommends the AWWA tool because it

provides actionable recommendations to improve the cybersecurity posture of water and wastewater utilities and can provide a foundation for longer-term implementation of a comprehensive cybersecurity risk management strategy.

As the availability of experienced staff changes due to global events and the availability of qualified personnel, bringing cybersecurity solutions up to date and keeping them there becomes more of a challenge. In response, many organizations are closing the cybersecurity skills gap with security automation.

The cybersecurity solutions built into Ovation can help strengthen security position in the majority of the areas that the AWWA tool examines. Malware prevention, user controls in Active Directory, system hardening, backup and recovery, and security perimeters, are all included. In addition to these standard features, the Power and Water Cybersecurity Suite offers additional modular and scalable options for security automation and compliance.