I saw an email from Process Automation Hall of Fame member, Greg McMillan, welcoming a new ISA Mentor Program protégé and resource (a.k.a. mentor). The goal of this program is to connect:

…early career professionals to more seasoned professionals who are willing to help coach, guide and share expertise. The program is conducted entirely online.

Greg also attached a presentation he had given at the AIChE Spring Meeting on the current state and recommended solutions for the automation engineering profession. He first highlighted the significant challenges:

- Books by experts like Shinskey are out of print

- Technology departments depleted or gone

- Experts from the 1970s technological peak are retired

- Practitioners gap due to hiring freeze in 1980s and 1990s

- Industry publications and presentations often not by practitioners

- Process production companies (users) reluctant to publish anything

- Emphasis on time and money and doing more with less

- Practitioners overloaded (no time or incentive for technical development)

- Few if any onsite technical courses and mentors or libraries

- Executives lack process control education, experience or understanding

- Change and experimentation viewed negatively leading to copy jobs

- Mistaken view that everything has been done and IIoT is total solution

Greg shared his ideas for how to best address these challenges:

- Develop and support Mentor Program Q&A and Webinars

- Develop and teach industry-based university courses and labs

- Detail best practices in courses, publications and presentations

- Increase innovation by process simulation and digital twin

- Conduct and implement opportunity sizing and assessments

- Deploy dynamic demos with “before” and “after” metrics

- Moving average for 12 hours (shift) and month (real time accounting)

- Coauthor publications and presentations with practitioners

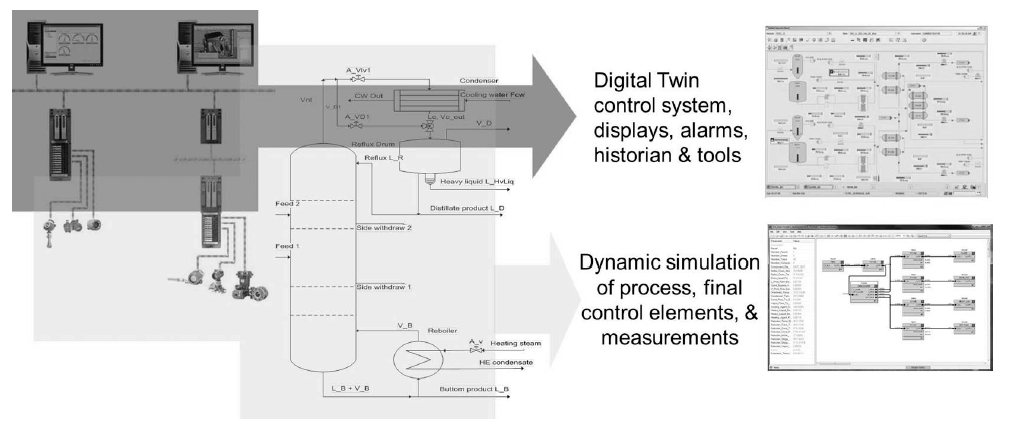

Finally, he shared how digital twin technology can drive innovation for improved project and operational performance across many phases of the lifecycle of a plant:

exploring <=> discovering <=> prototyping <=> testing <=> justifying <=> deploying <=> testing <=> training <=> commissioning <=> maintaining <=> troubleshooting <=> auditing => operator, system and process performance showing the “before” and “after” benefits of solutions from online metrics

Visit the ISA Mentor Program page for more on how to be a protégé or resource to advance the profession and make our plants and production facilities safer, more reliable and more efficient & sustainable.