Imagine you have been tweaking and tuning one of your control loops and have the perfect PID [proportional-integral-derivative] settings. Everything is working great for several months until it isn’t. Chances are that it’s the part of that loop doing all the manual work to keep the process running smoothly—the control valve. A poorly performing control loop can cause increased variability, increased probabilities for unplanned shutdowns/slowdowns, decreased quality—driving down overall operational performance.

Technology has advanced to help you avoid these valve issues leading to lower performance. But unless someone is paying attention to what the monitoring applications are finding, early problem-solving opportunities may be missed.

In an earlier post, Adding Experts in Valve Condition Monitoring, I highlighted an article by Emerson’s Fabrice Hoenig on supplementing the valve condition monitoring technology with experts. These remote experts could make sure these valve problems are spotted, recommendations communicated, and addressed locally on-site before it affects the process.

As one of the elements in the Plantweb digital ecosystem, Valve Condition Monitoring connects a global network of Emerson certified valve analysts to gather, analyze, and interpret data from your valves, and other assets. The valves, equipped with advanced technology such as Fisher FIELDVUE DVC6200 digital valve controllers, and operational analytics tools such as ValveLink software, are turned into data-driven, actionable recommendations by the analysts.

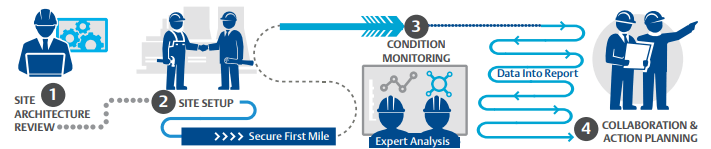

This Valve Condition Monitoring service can help move your maintenance activities from reactive or proactive to predictive to increase levels of reliability and to reduce variability. Implementing the service begins with a site network architecture review with Emerson cybersecurity experts and site or corporate IT/OT team to review site specifications and develop and agreed data communications architecture.

During site setup, detailed instrument configurations are performed, diagnostic tests are scheduled, and the secure data transfer methods are validated. Once in place, the Emerson analysts interpret time-series analysis and the analytics that have been automatically generated. This data is reviewed weekly by the analysts and recommendations are communicated for urgent issues.

Monthly reports are created summarizing the condition of all the valve assets being monitored. Analysts receive ongoing training with periodic peer reviews for technical accuracy and consistency. For issues uncovered, plants can work with their local Emerson service providers to discuss valve repair strategies and solutions.

These helping hands can assist in driving higher levels of availability, reliability, quality and overall production levels. Visit the Valve Condition Monitoring section on Emerson.com for more on this service and successes other manufacturers and producers have achieved. You can also connect and interact with other valve experts in the Valves, Actuators & Regulators group in the Emerson Exchange 365 community.