When dealing with issues related to environmental compliance, many engineers tend to stop thinking about the situation as soon as they reach the goal line. Compliance costs money, so they stop working on improving performance the instant they achieve the needed result.

This is unfortunate because an environmental compliance effort is also an excellent opportunity to examine interrelated equipment and process practices. This is one of the key points of my article in Fugitive Emissions Journal’s September 2020 issue. Upstream oil and gas production sites must comply with limits on VOC emissions, and this effort is a good time to examine all the related equipment.

This is unfortunate because an environmental compliance effort is also an excellent opportunity to examine interrelated equipment and process practices. This is one of the key points of my article in Fugitive Emissions Journal’s September 2020 issue. Upstream oil and gas production sites must comply with limits on VOC emissions, and this effort is a good time to examine all the related equipment.

As oil and gas producers and processors announce ambitious plans to measure, reduce, and report emissions over the medium- and long-term, it is easy to overlook what immediate, cost-effective equipment changes and process improvement practices can be incorporated to achieve environmental, social, and governance (ESG) goals. These changes and improvements can also build stakeholder confidence with respect to the reporting of greenhouse gases (GHG), volatile organic compounds (VOC), and hazardous air pollutant emissions.

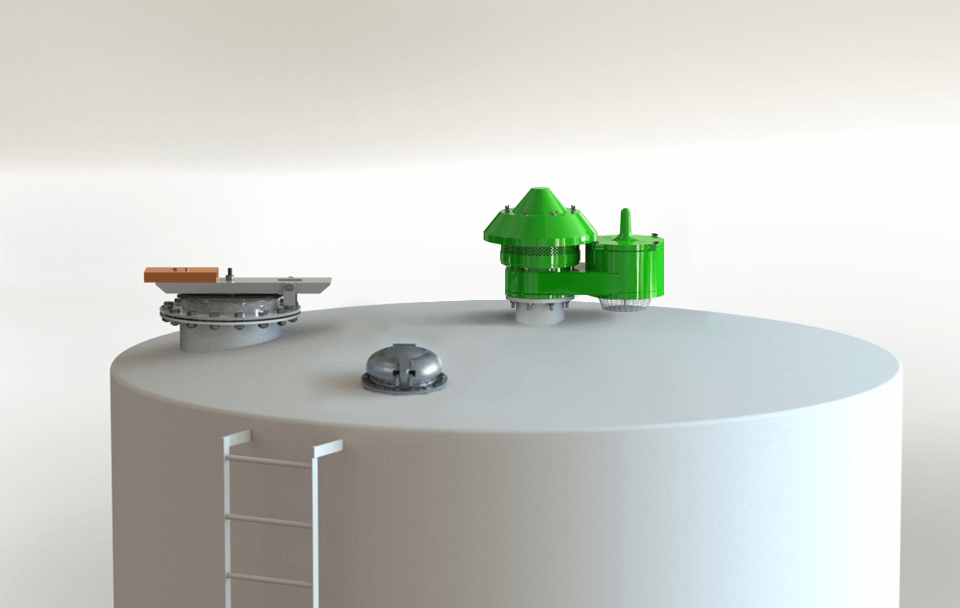

Take a look at all the valves and components involved in the larger tank venting system. The article elaborates on three main areas:

- Review the design and selection of vapor space pressure control devices to verify they’re sized correctly and seal completely.

- Ensure optimally staggered setpoints for vapor space pressure control devices.

- Develop a detailed maintenance plan to monitor device condition and operation.

The article goes into more detail so give it a full read. One of the most critical areas to monitor is how well the valves seal because this makes all the difference. Something as basic as the material of the seals themselves is critical. Emerson uses polyphenylene sulfide (PPS) for pallets and seats in its Enardo Series 850 High-Performance Pipe-Away Pressure Vacuum Relief Valves. These resist corrosion and are easily replaceable to improve upon a leakage standard of 1 SCFH @ 0% of set point.

So, have you optimized your vapor recovery system, or does it just meet regulatory requirements? Maybe it’s time for you to give it a look and see how improving it can improve your process.

Visit the Pressure/Vacuum Relief Valves pages at Emerson.com for more on technologies and solutions for vapor emission control. You can also connect and interact with other engineers in the Oil & Gas Groups at the Emerson Exchange 365 community.