Wireless communications have fundamentally changed the way we live and work. This technology continues to advance industrial automation sensors, control elements, systems and software. In a Valve magazine article, In the Air: Wireless Trends in Smart Pneumatics, Emerson’s Adam Gibson describes how its use in pneumatic components help manufacturers improve operations.

Adam opens describing the importance of pneumatic technology in automation.

Pneumatics is one of the most widely used and effective technologies in today’s automation systems. Pneumatic systems are ideal because they are proven to provide long operational life, as well as a low-cost and effective way to add various motion to equipment.

Wireless communications combined with onboard intelligence, makes it:

Wireless communications combined with onboard intelligence, makes it:

…easier to monitor pneumatic actuators and valves and get actionable data without being cost-prohibitive. Pneumatics now ties in with the overall automation system to provide comprehensive, actionable performance data that can improve overall equipment effectiveness (OEE).

Access to this data enables plant staff:

…to immediately respond to problems and issues with pneumatic components and to correct them before they cause significant problems or lead to significant downtime for automation systems.

It also enables a shift from traditional maintenance practices to:

…more predictive maintenance programs, helping to prevent unscheduled downtime by planning for component servicing and replacement in the most efficient manner possible.

Adam shares an example of how intelligent devices and wireless communications simplify valve commissioning and configuration.

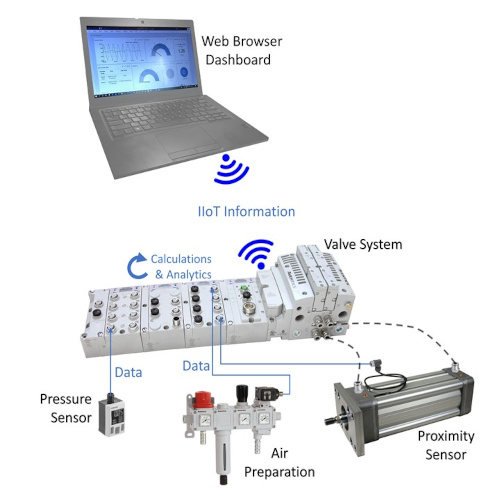

A pneumatic fieldbus valve system [AVENTICS G3 Fieldbus Platform] connects to sensors incorporated with an automation system’s pneumatic components. The system then captures and manages the data that sensors collect to provide operators access to valve status and diagnostics through a web browser dashboard. These fieldbus valve systems replace conventional hardwired solutions and integrate communication interfaces and input/output (I/O) capabilities to pneumatic valve manifolds.

Read the article as he discusses a range of automation communications protocols available, valve system modularity, web-based diagnostic, commissioning and configuration dashboards, machine productivity and energy efficiency real-time monitoring, and how these technologies support digital transformation initiatives.

Visit the AVENTICS G3 Electronic Fieldbus Platform page on Emerson.com for more on how this platform integrates communication interfaces to pneumatic valve system with input/output (I/O) capabilities and enables distributed control systems and programmable logic controllers to more efficiently turn valves on and off, and to channel I/O data from sensors, lights, relays, individual valves, or other I/O devices via various industrial networks.