In an Automation World Article, Digital Transformation in Manufacturing: Small Steps or One Giant Leap?, Emerson’s Zach Gustafson shares how:

…taking three practical steps can generate short-term wins and achieve long-term success with Industrial Internet of Things technologies.

He opens noting how a recent Emerson survey:

…shows that more than 70% of companies don’t have a vision for data analytics with a clear roadmap to success.

An Industrial Internet of Things (IIoT) device:

An Industrial Internet of Things (IIoT) device:

…allows you to gather process data from previously “unintelligent” components like valves, cylinders, and air preparation units. After collecting this data and transmitting it to gateways and other aggregation hardware and software systems, you can unlock new production insights that lead to less downtime, lower energy costs, faster cycle times, and higher overall productivity.

For example, the AVENTICS AF2 series flow sensor collects and shares pneumatic air consumption and leak detection analytics which can help in driving lower energy costs and improved reliability.

Zach’s three practical steps include:

- Figure out what you’re looking for

- Start small and scale: field-level intelligence

- Don’t lock yourself in: open tools and protocols

It’s starts with being clear on your objectives.

One of the most important steps on the road to digital transformation is to figure out your goal, and then pick out actionable data that can inform and drive your decisions. For example, if you’re looking to reduce your energy costs, it would be helpful to know how much energy you’re currently consuming, as well as any sources of potential waste.

He notes these initiatives are not all or nothing, but rather:

…a simple, yet effective IIoT approach: start small and scale over time. For example, once you figure out your production goals, design your system and assess your return-on-investment (ROI) objectives, the next step is to start with a small pilot project on a few machines.

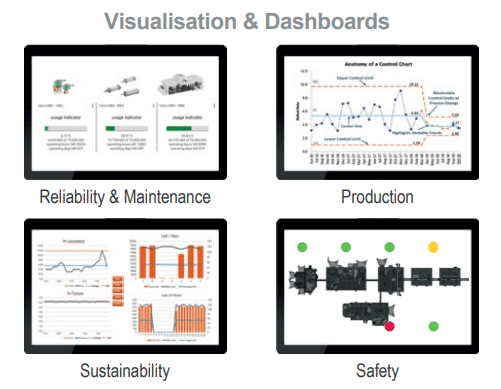

Read the article for more on these three practical steps as well as some open-source data aggregation, database and visualization tools to assess this IIoT information in industrial PCs and edge controllers and transmit the information to the cloud for further analysis.