It’s always good to come across a story how automation technology improves the food and beverages we consume—especially in my personal opinion, the adult beverages. In a ProFood article, Passing the Test, Absolut Vodka shares their story of using diagnostics to assess the health and performance of their flow measurement devices.

It’s always good to come across a story how automation technology improves the food and beverages we consume—especially in my personal opinion, the adult beverages. In a ProFood article, Passing the Test, Absolut Vodka shares their story of using diagnostics to assess the health and performance of their flow measurement devices.

Their plant 100 million liter per annum plant in Sweden [hyperlinks added]:

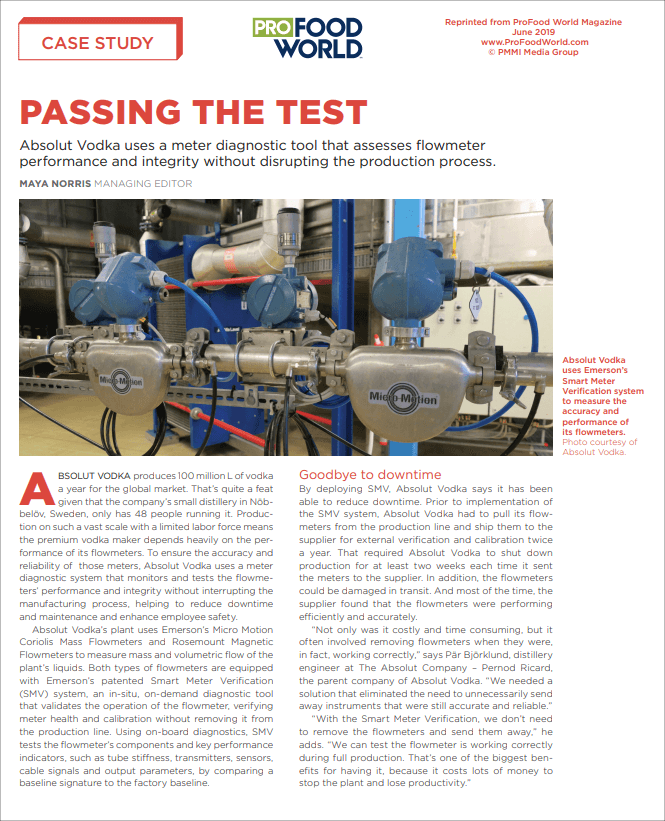

…uses Emerson’s Micro Motion Coriolis Mass Flowmeters and Rosemount Magnetic Flowmeters to measure mass and volumetric flow of the plant’s liquids. Both types of flowmeters are equipped with Emerson’s patented Smart Meter Verification (SMV) system, an in-situ, on-demand diagnostic tool that validates the operation of the flowmeter, verifying meter health and calibration without removing it from the production line.

Before SMV, they:

…had to pull its flowmeters from the production line and ship them to the supplier for external verification and calibration twice a year. That required Absolut Vodka to shut down production for at least two weeks each time it sent the meters to the supplier. In addition, the flowmeters could be damaged in transit. And most of the time, the supplier found that the flowmeters were performing efficiently and accurately.

Now, with SMV:

…we [plant staff] don’t need to remove the flowmeters and send them away… We can test the flowmeter is working correctly during full production. That’s one of the biggest benefits for having it, because it costs lots of money to stop the plant and lose productivity.

Bimonthly, they are able:

…to test the flowmeters inline twice a month without any downtime. Technicians schedule and automate the tests, which can verify and check the calibration of the meters in 90 seconds within a 0.1 percent accuracy…

Here’s how they perform these tests with AMS Device Manager, the Smart Meter Verification SNAP-ON and the wireless THUM adapter.

The flowmeters are wirelessly connected to Emerson’s AMS Device Manager software and Smart Meter Verification SNAP-ON application via the Emerson THUM Adapter. When the Smart Meter Verification SNAP-ON application is launched from the AMS Device Manager, the SNAP-ON application checks and captures device configuration and zero calibration level, sensor structure, electronics, and signal processing for complete verification of meter performance. It also trends and reports test results for test traceability and easy data management.

Read the article for more on remote monitoring, predictive diagnostics, and using the information for regulatory reporting. Visit the Smart Meter Verification section on Emerson.com for more on this automatic meter diagnostic software that monitors the entire flow meter’s performance and integrity – without requiring you stop your process. You can also connect and interact with other flow measurement and food & beverage industry experts in the Measurement Instrumentation and Food & Beverage groups in the Emerson Exchange 365 community.