Safety is of paramount importance in mining operations—both personnel and process. But what role can today’s rapidly advancing technologies play? From a personnel safety standpoint, miners need identification of personnel in case of emergency with access control and record of working hours inside the mine.

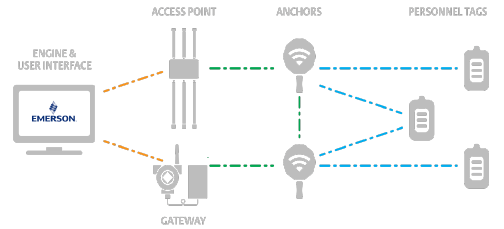

It’s also important the location of personnel be known in the event of an emergency. Wireless technology, as part of the Industrial Internet of Things (IIoT) enables wireless tags on mining staff that communications back with WirelessHART applications to send this location information up and out of tunnels for continuous location awareness. These same devices can also manage personal access and working hours for operations staff.

It’s also important the location of personnel be known in the event of an emergency. Wireless technology, as part of the Industrial Internet of Things (IIoT) enables wireless tags on mining staff that communications back with WirelessHART applications to send this location information up and out of tunnels for continuous location awareness. These same devices can also manage personal access and working hours for operations staff.

Another critical need for improving personnel safety is continuous hazardous gas monitoring. Many mining operations are in remote locations and have harsh operating environments. Wireless technology can again make what may have challenging to install and maintain, much simpler.

Wireless gas monitoring solutions can detect the presence of nitrogen/carbon, dioxide/carbon, monoxide/nitrous, gases/sulfur, dioxide/hydrogen sulfide. Wireless gas sensors enable remote monitoring and control. Not only does this improve safety for mining personnel but also can improve environmental performance.

Methane is another gas frequently found in mine shafts. Methane levels are typically controlled with fans introducing clean air into the location. Reliable performance of these fans is critical for safe operations. Continuously monitoring the mechanical condition of these fans can help identify performance issues before they lead to unplanned shutdowns. Monitoring for vibration enables prescriptive analytics on the vibration data to automatically identify failure modes in rotating equipment.

Methane is another gas frequently found in mine shafts. Methane levels are typically controlled with fans introducing clean air into the location. Reliable performance of these fans is critical for safe operations. Continuously monitoring the mechanical condition of these fans can help identify performance issues before they lead to unplanned shutdowns. Monitoring for vibration enables prescriptive analytics on the vibration data to automatically identify failure modes in rotating equipment.

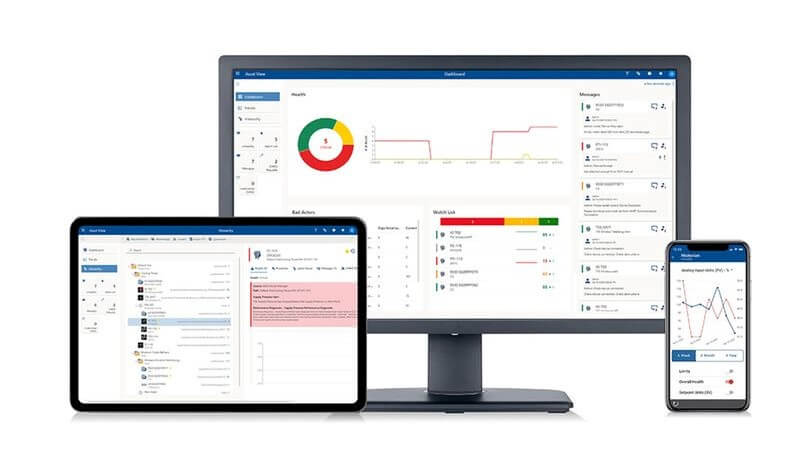

These analytics can be aggregated with the Plantweb Optics asset performance platform to provide mobile alerts to abnormal conditions and provide a holistic picture of overall health of the production operations.

To assess your mining operations to improve safety performance and reduce operational costs, Emerson mining industry experts can work with your staff to interview stakeholders and perform walkdowns. This discovery process enables a consulting assessment and review of the technologies and work practices that can drive performance improvements.

Visit the Mining, Minerals & Metals section on Emerson.com to learn more about the technologies and assessment and project justification process.