With technology supported by our experts, we offer comprehensive solutions to our customers’ challenges. We have developed Emerson’s Zedi Autonomous Rod Pump Management for an advanced solution using artificial intelligence with machine learning capabilities.

With technology supported by our experts, we offer comprehensive solutions to our customers’ challenges. We have developed Emerson’s Zedi Autonomous Rod Pump Management for an advanced solution using artificial intelligence with machine learning capabilities.

What is an Autonomous Rod Pump?

Autonomous Rod Pump Management is an Artificial Intelligence (AI) application (analytics engine) that identifies anomalies on rod pump applications.

Autonomous refers to a state of equipment where it can perform the programmed operations under defined conditions without human input or guidance. When we talk about this type of equipment, we use the adjective, autonomous.

The main function of artificial lift technology is to increase production and maximize hydrocarbon production and recovery from the reservoir. It accomplishes this through optimizing the bottom hole flowing pressure in order to increase the flow rate or generate flow where when the reservoir pressure becomes too low over the lifespan of the well. Rod pumps are the most common artificial lift system and utilized in onshore operations, most notably in the unconventional oil plays such as the Permian and Bakken.

Our Autonomous Rod Pump Management replaces the data analysis performed by the operator and engineers and then takes appropriate responses to common problems such as paraffin buildup, over/under pumping, gas lock/interference and sticking pumps.

How does an Autonomous Rod Pump Work?

Sensors are placed on rod pumps for each well to collect data into Emerson’s Zedi SaaS SCADA platform then viewed in Zedi Access, that also has a mobile app Zedi, so you can access your data anytime, anywhere. Our cloud-based platform is built for oil and gas producers for remote SCADA monitoring, control, and optimization at the well pad—regardless of the field device used at the site.

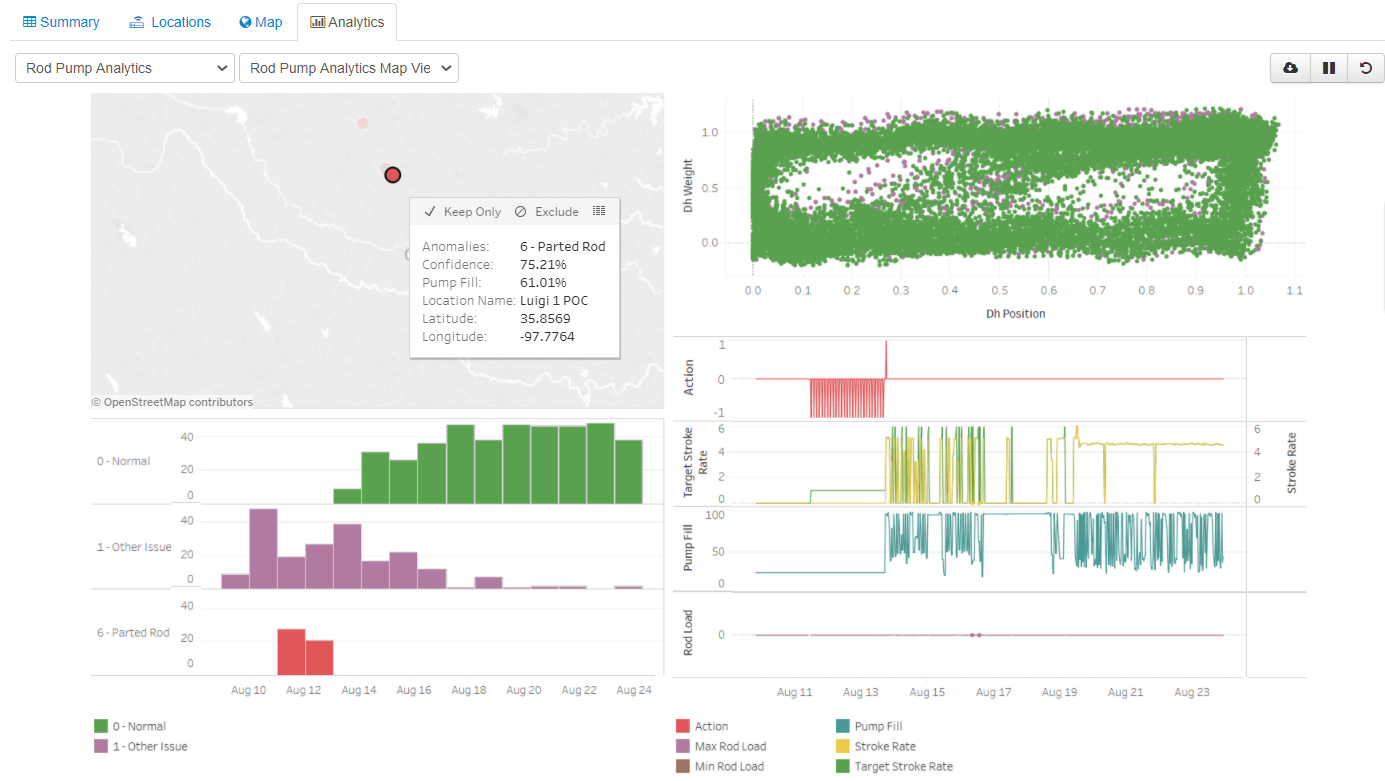

As data arrives into Zedi Access, the analytics engine will analyze pump cards and other data and will indicate its assessment on a dashboard. Once an anomaly is identified, the analytics engine will autonomously correct the situation by issuing commands to the Variable Frequency Drive (VFD) remotely, allowing companies to better utilize personnel’s time on other operational areas.

Corrective actions consist of sequences of commands to the VFD to adjust the stroke rate as needed just as an operator would do based on the type and severity of the anomaly. It is worth noting that our autonomous rod pump solution comes with all the benefits that Zedi Access can offer, such as alarming. In this case an alarm would be triggered if an anomaly is detected.

Our autonomous rod pump dashboards show relevant data and health status of the pump, e.g. pump cards, pump fill, rod loads, current stroke rate, type of anomaly detected, target stroke rate as set autonomously by the AI engine, etc.

Benefits of Autonomous Rod Pump

Companies with high-output wells would benefit most from our solution. Some key benefits include:

- Reduce unexpected downtime and resulting workover costs, through automatically responding to changes in operating conditions and alerting operators to potential issues

- Maximize production using the least amount of capital

- Minimize the effort required to retrofit the well and keep it running with the highest possible output

- Increase safety within your organization through enabling reduced site visits and less windshield time

- Use the smallest number of resources to add these additional lift capabilities to the wells and operate the well, given that labor is a significant proportion of operating costs, especially in remote locations

Operators have many wells to monitor and control, and not enough time to respond to all situations. Your organization can now reduce the time spent analyzing data with our machining learning capabilities that enable our solution to identify anomalies and provide quick corrective responses.

Visit Emerson’s Zedi Autonomous Rod Pump Management page as well as the complete suite of Zedi SaaS SCADA Solutions for more on the software and solutions to drive improved oil & gas production performance.