Original Equipment Manufacturers (OEMs) also look for ways to drive digital transformations in the equipment they provide to their customers. A great example comes from a Packaging World application note, Machine Condition Monitoring via IIoT.

Original Equipment Manufacturers (OEMs) also look for ways to drive digital transformations in the equipment they provide to their customers. A great example comes from a Packaging World application note, Machine Condition Monitoring via IIoT.

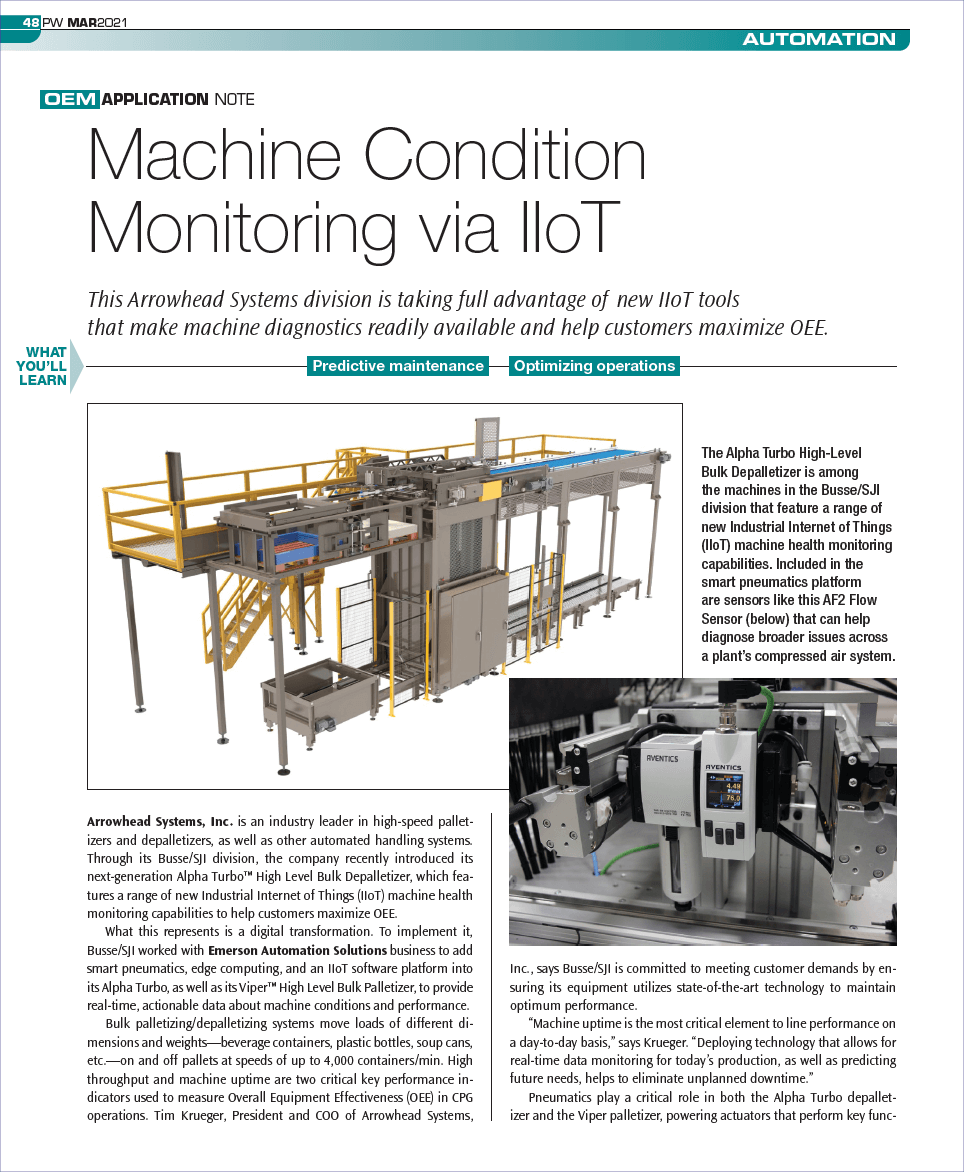

The article highlights the collaboration between Arrowhead Systems and Emerson on their, “…next-generation Alpha Turbo High Level Bulk Depalletizer…” as well as their Viper High Level Bulk Palletizer. These systems:

…move loads of different dimensions and weights—beverage containers, plastic bottles, soup cans, etc.—on and off pallets at speeds up to 4,000 containers/min.

Critical key performance indicators are throughput and machine uptime. These pneumatically powered systems drive mechanical motion for actions such as:

…trapping and guiding empty containers into and out of the machines and grabbing, lifting, and placing the slip sheets to help in stacking containers.

Overall equipment effectiveness (OEE) on the depalletizer is improved:

…by monitoring critical motion and pneumatic system parameters, including airflow, pressure, vacuum, mechanical actuation speeds, and motor vibration.

These IIoT-based sensors can provide early detection of issues with pneumatic cylinders and actuators, system air pressure, and visualizations for the machine operators. AVENTICS smart pneumatics, AMS vibration sensors, and the PACEdge 2.0 IoT platform and RXi2 Edge Computer brought to these systems:

…a comprehensive IIoT solution for real-time data access, historical performance tracking, and visualization and analysis of the smart pneumatic system.

Read the article for more on the collaboration between Arrowhead and Emerson to help drive improved performance and increased visibility to these palletizing and depalletizing systems.

Visit the Packaging section on Emerson.com for more on the technologies and solutions to drive reliability, production, safety and sustainability improvements. You can also connect and interact with other packaging experts in the Fluid Control & Pneumatics and PLC, PAC Systems & Industrial Computer sections in the Emerson Exchange 365 community.