Figure 1: Tailing material is viscous and abrasive, creating a very difficult application for automated valves.

I recently published an article in the April 2021 issue of Global Mining Review. The article describes the difficulties of tailing disposal, and it provides suggestions for choosing the proper automated isolation valves for this service. The article is titled Making the Difficult Choices and is summarized below.

Tailings are the leftover materials and waste generated from mining operations, and its disposal can be a major problem. Tailings primarily consist of dewatered pulverized rock, dirt, and gravel—and the material is viscous, dense, abrasive and may even be considered hazardous (Figure 1). When tailings flow through an automated isolation valve, there are significant valve selection challenges.

Since mining extraction operations are often located far from the tailings’ containment ponds, the material must be piped over long distances. The long pipe runs and viscous nature of the tailings usually requires high-pressure pumps to move the material. Once the material reaches the containment pond, it must be distributed evenly across the surface. This is accomplished by adding several smaller pipes, called spigots, to divert the material to various locations around the containment area (Figure 2).

Figure 2: Spigot pipes tee off the main tailing distribution line to feed various sections of the containment area. Each spigot has an isolation valve to control tailing flow.

Each spigot has an automated isolation valve that can be operated as necessary to ensure the containment area fills uniformly. These valves must seal reliably, despite the difficult service.

Tailing Valve Challenges and Selection

Most tailing distribution systems utilize knife gate valves designed for handling slurries, but the viscosity, low water content, and abrasiveness of the material tends to wear the valve body quickly and degrade the elastomer seats necessary for valve sealing and shutoff. The valve selection process is tricky:

Line pressure can be very high in the distribution network, yet relatively low at the spigots due to pressure drop in the very long pipelines. This means that different valve designs may be necessary in different locations. Hazardous tailings, such as those often found in oil sand applications, may require zero-leakage, ASME-rated valves to eliminate leakage outside the designated containment dike.

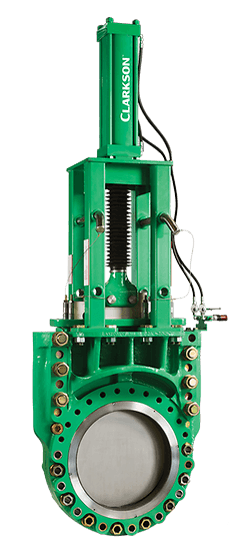

Figure 3: Knife gate valves, like this Emerson Clarkson Model KGA+, are often used in spigot pipeline service for tailing systems. The valve is full bore, easily maintained, and provides bubble-tight shutoff.

In many mines, the spigot valve is a low-pressure application that is located inside the containment dike, so a standard low-pressure knife gate valve (Figure 3) may suffice.

The valve should be full bore to reduce wear, and it should incorporate strengthened, long-life elastomers to create tight line shutoff and extend service life. Wearable valve components should be easily inspected and replaced. Discharge to the environment is acceptable in a valve in this application, but it should be minimized.

Figure 4: For higher pressure and/or hazardous applications, ASME Class 150 valve with zero atmospheric discharge, such as this Emerson Clarkson KS1, are usually required.

As the valves move upstream in the tailings distribution network and experience higher velocities and pressures, or if hazardous materials are involved, a different valve design is necessary. Hazardous tailing applications require zero atmospheric leakage and the higher pressures usually require true ASME Class 150 ratings (Figure 4).

Valves for these applications must be full bore and employ replaceable wear rings on the valve body to absorb the brunt of the abrasive forces and extend valve life. The valves should be fully bi-directional and provide the required zero-leakage shutoff.

The tailing valves near the extraction area must withstand extremely difficult conditions. Here’s the problem:

Valves located near the beginning of the tailing distribution network face the most demanding process conditions. They are often subjected to very high pressures and abrasion rates, yet still must provide zero leakage line shutoff while maintaining the zero atmospheric leakage required for hazardous tailing applications. Selecting the right valve for this service is therefore critical, but can also be very difficult.

Higher pressure applications require ASME Class 300 service, which is relatively uncommon in a knife gate valve. The valve port must be round and full bore to minimize turbulence and abrasion, and the valves should employ replaceable and rotatable wear rings to maximize service life (Figure 5).

Figure 5: Very high-pressure, high-solids applications pose the most difficult challenges for knife gate valve design. These valves require ASME Class 300 valve ratings, zero atmospheric discharge, and a special body design to handle high velocity abrasive material, like this Emerson Clarkson ZP300.

Seal design is critical for high-pressure applications, so the design of the valve shutoff and atmospheric seals should be examined carefully. Proper selection of soft seat materials, as well as easily replaceable internal components, are critical for long service life and lowest total cost of ownership.

A failure to select the right valve usually results in a significant waste of time and money as noted in the article.

Some users fail to consider the requirements for a specific application and install whatever gate valve they happen to have in stock. This either results in a valve that is far more expensive than required, or, more commonly, a valve that is poorly suited for the task. In that situation, premature seal failures, poor shutoff, and high maintenance costs typically result.

However, when the failing knife gate valve is replaced with a correctly designed model, the improved performance and greatly reduced maintenance typically pay for the upgraded valve quickly. If a valve requires frequent repairs, it is likely a good candidate for a re-evaluation and possible replacement.

Visit the Clarkson Knife Gate Valves section on Emerson.com for more on these valves for slurry flow applications.