At the Emerson Exchange Americas virtual series, Emerson’s Reid Youngdahl, Trevor Stoakes and Michael Wyatt show ways to visualize control valve noise and ways to reduce it. Here is their presentation abstract:

Control Valve Noise Reduction: ‘See the Noise Around You’ session will give you a look inside the Emerson Innovation Center at our laser shadowgraph flow visualization technique, which demonstrates the principles of aerodynamic noise exit jet formation. We will explain how controlling these jets with noise attenuation technologies can significantly reduce valve noise in large pressure drop applications and give you an overview of Emerson’s Fisher Whisper Trim cages.

Trevor opened the presentation noting that their focus was on gas fluids flowing through valves. Two noise concerns are acoustic noise and vibration. Personnel safety is affected if acoustic noise exceeds standards. Vibration can lead to plug damage when the level exceeds normal operating conditions. Vibration can lead to a snapped valve stem.

Michael shared some ways to mitigate the noise including thicker schedule pipes or pipe insulation. Acoustic noise can propagate down the pipe. Source treatment is where you attack the source of the noise at its source at the control valve. The type of cage inside the control valve can affect the noise.

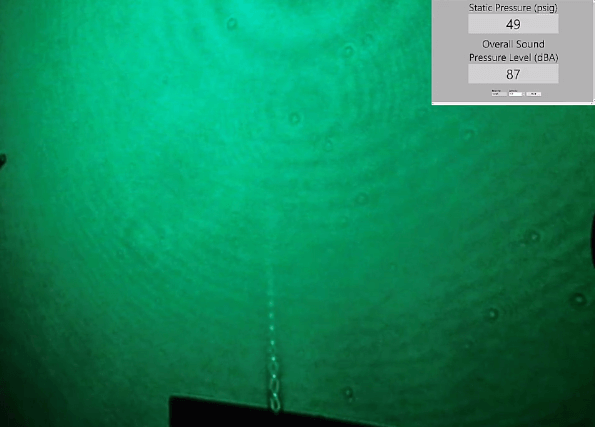

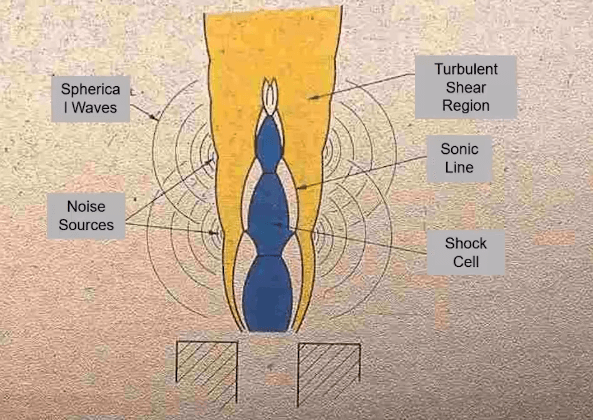

He demonstrated pulsating air through a pipe with a laser that creates a shadow graph to visually display the air flow. He showed different cages in the control valve and the effect they had on mitigation including a standard window cage and Whisper Trim cages including Whisper Trim I and Whisper Trim III. Models have different spacing between the holes in the Whisper Trim cages depending on the requirements of the application.

The tradeoff for noise attenuation is flow capacity through the control valve. The spacing between the holes also dictates when the separate gas fluid screens recombine that causes a loss of noise attenuation. A baffle outside the Whisper cage can further reduce recombination of the streams.

Here’s the shadow graphic of the standard window cage:

Michael explained the components of the jet displayed above:

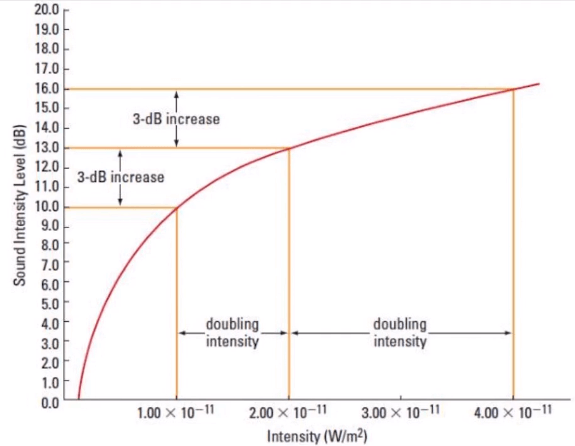

Noise intensity is a logarithmic scale.

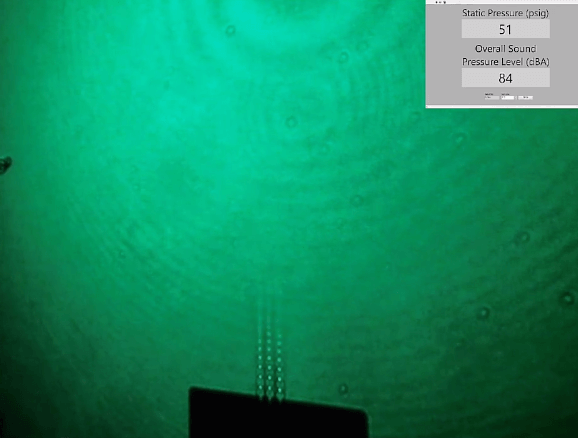

With one of the Whisper cages, the dBA level goes from 87 to 84 where the acoustic noise is cut in half:

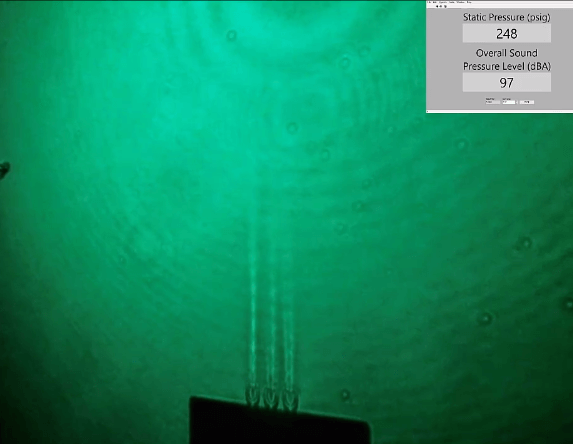

With wider spacing between holes, much higher PSI is possible without recombination of the streams:

Whisper 3 can reduce attenuation by about 30 dBA. For even greater noise reduction, WhisperFlo can be used. It has a much thicker cage profile. This allows the pressure drop to occur in stages. It is designed to reduce the noise level up to -40 dBA. For special applications, -50 dBA attenuation can be achieved.

Visit the Control Valve Noise Reduction section on Emerson.com to learn more about the Fisher noise-attenuation trims for control valves that help provide the necessary degree of noise reduction for your application.