More and more companies are digitalizing their operations. After all, collecting data on paper and transferring those records to digital systems is inefficient and subject to error, not to mention the fact that few plants have the staff needed to perform these labor-intensive tasks. But digitalizing data is only the first step. As Claudio Fayad details in his recent article in CIO Applications, data democratization should be the ultimate goal.

Cross-functional teams operate more effectively with access to rich data.

It isn’t terribly difficult or complex to aggregate data in one place using technologies such as data lakes, but sharing data is not enough. Claudio explains,

“True data democratization means making the right information continuously available to the right people, hassle-free. Such a solution requires an operational technology platform allowing any team in the plant with the right credentials to easily access data and generate insight that will foster innovation.”

Data in context

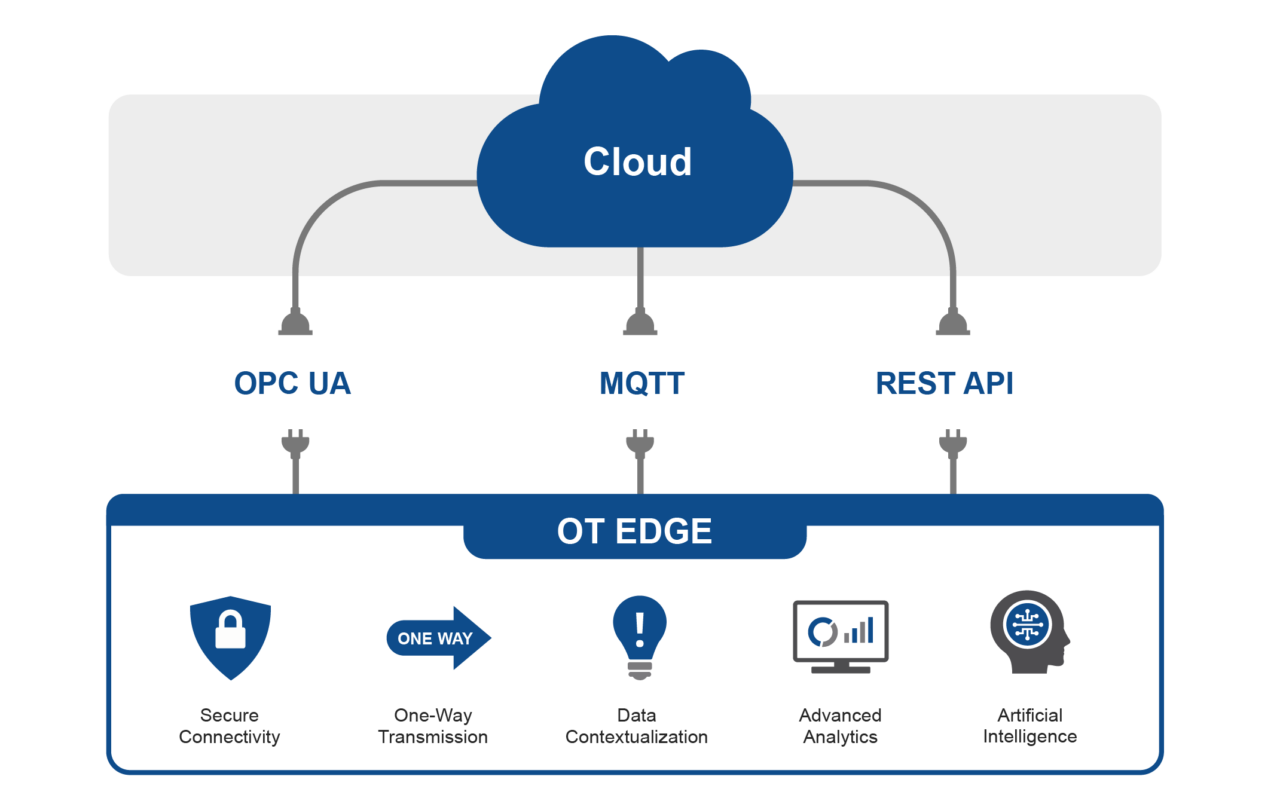

To truly be valuable, data requires context. Unconnected data points in a data lake quickly turn into a data swamp, with terabytes of information nobody can use effectively or efficiently. Instead, teams need rich data, complete with metadata for contextualization that makes the information they require searchable and discoverable. The operational technology (OT) edge can bridge this gap.

Emerging OT edge technologies help democratize data to drive increased innovation from cross-functional teams.

OT edge technologies securely collect and deliver contextualized data to aggregators like data lakes, empowering cross-functional teams to use that data in cloud systems such as machine learning/artificial intelligence algorithms, scripts, smart reports and more. Armed with this valuable data, Claudio explains,

“manufacturers can improve productivity by 5-10 percent or more.”

Emerson uses connect secure OT edge technologies to gather contextualized data from the DeltaV™ distributed control system and securely deliver it to a centralized repository, where cross-functional teams can use it to make better business decisions. Using data diodes, zero-trust architecture, and other technologies, engineers can ensure that transmission is entirely one-way—from the control system outward—enabling secure visibility of control and optimization data in real-time.

To learn more about how OT edge technologies are breaking down silos and democratizing data, you can read the article in its entirety at CIO Applications. You’ll also see examples of how data democratization impacts common plant issues. And while you’re here, please take a moment to comment below and share the strategies your teams use to ensure your data does everything you need it to.