Industry is moving away from the traditional model that locks the control system away from any internet connectivity. As Claudio Fayad, vice president of technology for Emerson’s process systems and solutions explains in his recent article in Process and Control magazine,

“In recent years most organizations have come to realize that the connectivity of all OT systems to the internet, along with cloud connectivity, are necessary to deliver Industry 4.0 performance benefits not just across the plant, but across the enterprise.”

Delivering on the value of data

The distributed control system (DCS) touches nearly every piece of data used by process manufacturers, and along the way, it adds critical context that can be used in analytics systems to improve operational performance. But while all that data is incredibly valuable, it also has the potential to make things more complex—the data must pass through many layers, including the controllers themselves, to make it to cloud systems.

Any connectivity between the DCS and the cloud needs to be secure. But there are technologies available today that are making that happen. Claudio explains,

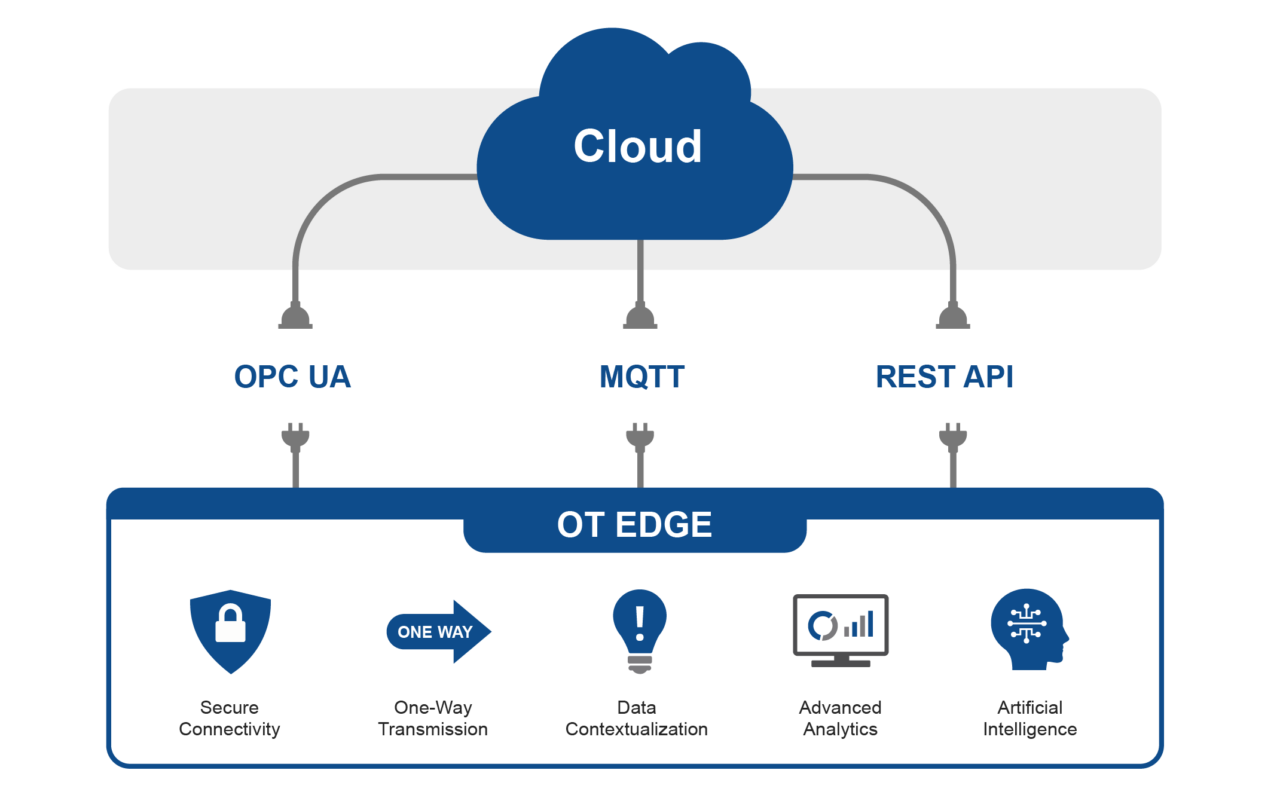

“Emerging OT edge technologies will provide intuitive, secure integration via one-way transmission using a data diode. These secure OT edge gateways will connect with operator and engineering workstations to display standard control data alongside optimization details to help cross-functional teams collaborate for improved performance – and they will connect to IT systems on premises or in the cloud.”

Emerson’s edge technologies are helping the control system meet the needs of Industry 4.0 and beyond.

Moreover, new industrial standards such as NAMUR’s Verification of Request, and more modern interfaces and protocols like REST API, MQTT, and OPC UA are expanding connectivity while still providing ways for OT to keep critical systems secure.

An exciting moment for automation

But while these changes are big, they’re not nearly as big as what Claudio reveals to be on the horizon for control systems. Future control systems, he suggests, will operate as extensible sandbox environments. Users with the right skill and credentials will be able to extend the functionality of the control system by creating their own customized packages they can connect through secure APIs and HTML5 frameworks.

Claudio explains that while some of this capability is in the future, much of the foundational technology is available from Emerson today. Emerson offers a wide range of OT edge technologies to democratize valuable control system data and drive it to the enterprise, where cross-functional teams can use it to make better business decisions.

If you’re interested in learning more about the future of control technology and Industry 4.0, you can read Claudio’s article in its entirety at Process & Control. You can also see some of these exciting technologies in action at our annual #EmersonExchange customer event from Oct. 24-28 in Grapevine, Texas. I hope to see you there!