At the 2022 ARC Industry Forum in Orlando, Emerson’s Nathan Pettus joined an executive panel moderated by ARC Advisory Group President and CEO Andy Chatha. The panel included PureCycle COO Dustin Olson, ExxonMobil Chief Automation & Process Control Engineer Whit McConnell, and GE Digital GM for Power Generation, Oil & Gas, Linda Rae.

Nathan opened by sharing Emerson’s history and breadth. He then shared the company’s “Greening Of, Greening By, and Greening With” sustainability framework. The most significant opportunity is to help Emerson customers improve efficiency, reduce emissions and reduce waste.

Nathan opened by sharing Emerson’s history and breadth. He then shared the company’s “Greening Of, Greening By, and Greening With” sustainability framework. The most significant opportunity is to help Emerson customers improve efficiency, reduce emissions and reduce waste.

Nathan shared examples from the Covid vaccines manufactured with Emerson control systems & technology, managing the growing complexity in the power grid, and making many manufacturing industries more productive.

He explained how Emerson combines advanced technologies, industry-leading expertise, and an insatiable curiosity about the world around us to create sustainable solutions for the essential customers we serve.

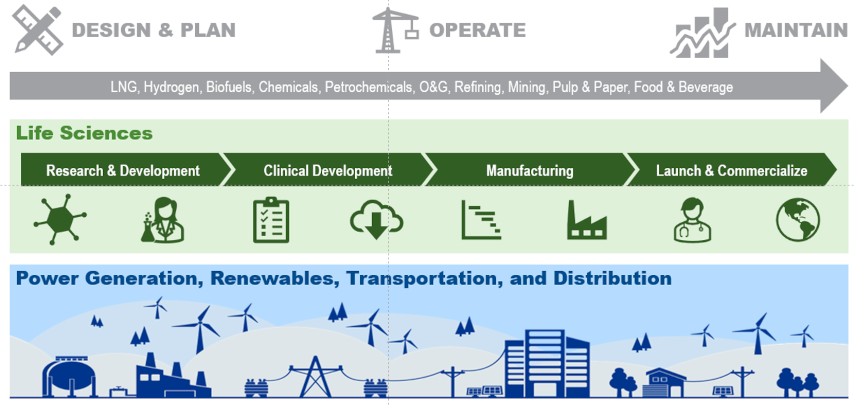

Nathan touched on the recent announcement of the completion of the transaction for the combination of Emerson’s industrial software businesses – OSI Inc. and its Geological Simulation Software business – with AspenTech to create a global industrial software leader. The portfolio of industrial software spans the solutions across the lifecycle of manufacturing and production across numerous industries.

PureCycle’s Dustin Olson noted that remote work practices open up the opportunity to hire the best people no matter where they live. The flip side is that the absence of face-to-face collaboration makes it much harder for new employees to acclimate to the company culture. Leadership needs to find opportunities for in-person gatherings that have a specific purpose.

ExxonMobil’s Whit McConnell described how Covid forced a rethinking of factory acceptance testing (FATs) to be performed virtually. The lockdowns forced alternatives to be explored and rapidly deployed to keep business continuity during the difficult lockdown times. He also explained that flexibility and empowerment are essential, but in-person collaboration has tangible benefits and fosters innovation.

Nathan highlighted how supply chain challenges have forced new ways to work around the obstacles, from alternative suppliers to alternative manufacturing locations. It remains a considerable challenge for the operations and supply chain staff to find the components required for the technologies and solutions for the global customer community.

The panel fielded many questions from the assembled audience, including what to prioritize, keys to success in digital transformation initiatives, and how digital transformation is tied to sustainability initiatives. Some common responses from the panelists were building early successes, engaging the people most affected in the transformation for participation and buy-in, and spending the most time in the culture and work processes, not the technology.

The panelists shared many practical ideas and planted ideas for some next steps in the minds of many in the audience.