Hydrogen as an energy carrier continues to receive intensive attention and research as a solution for global decarbonization efforts. In an H2Tech article, Scaling up green H2: Five critical steps to success, Emerson’s Nicolas Marti “…addresses five critical actions that H2 providers, particularly OEMs [original equipment manufacturers], must take for decarbonization through green H2 to become a reality.”

Nicolas opens by citing some statistics.

Nicolas opens by citing some statistics.

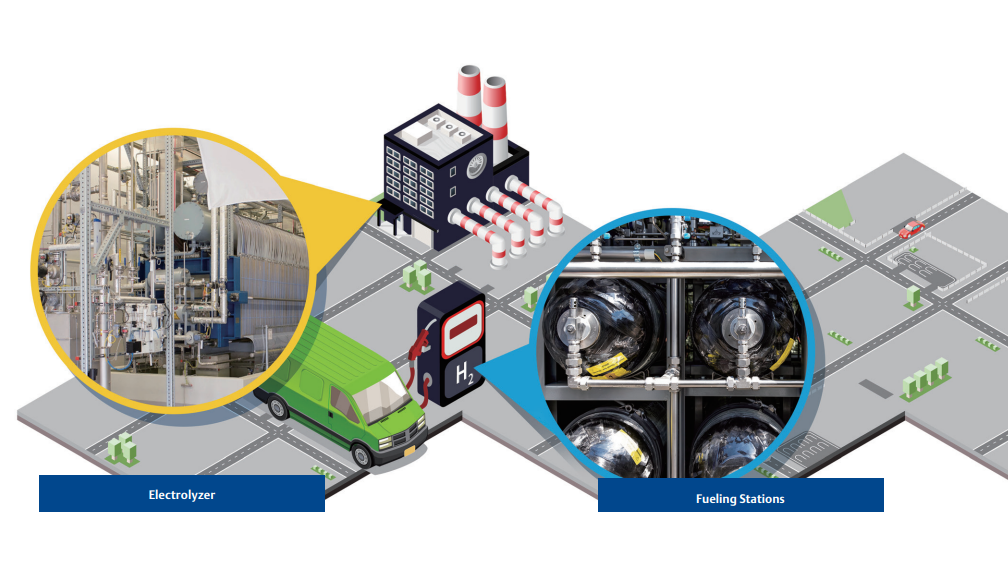

Today, fewer than 600 H2 fueling stations1 are in operation around the world and only 0.2 GW of green H2 is produced per year.2 By 2030, however, the global demand for green H2 is expected to reach 200 GW and an estimated 10,000 fueling stations will be in use.

His five steps to meet this tremendous growth include:

- Scale designs and capacity responsively to market demand

- Keep projects on time and on budget

- Reduce cost and complexity of production and distribution

- Select scalable, advanced technology platforms

- Use the correct components for safe and reliable operation

He shares an example of how one technology used in hydrogen production could benefit from automation technology.

For proton exchange membrane (PEM) electrolyzers, reaching maximum efficiency is linked to accurately measuring the ratio of O2 and H2 production as the product gases exit the electrolyzer stack. To achieve this, consider using a backpressure hydraulic regulator loop with an electropneumatic PID (proportional integral derivative) controller.

Digital technologies can be essential in proving new technologies and managing projects.

Dynamic simulation software, for example, can be used to create a digital twin of a physical environment, helping to optimize process and products before they are commissioned. Digital twin solutions allow OEMs to perform advanced testing for compatibility and other issues, as well as to train operators without affecting running processes. In this way, digital twins are able to reduce startup and commissioning time, improve project execution and mitigate risk.

Nicolas highlights other examples where instrumentation and automation can play a role in scaling up the production and distribution of hydrogen through its supply chain. These examples include thoroughly tested & certified integrated solutions panel for OEMs, educational resources for new technologies, leak detection & optimized pneumatic consumption technology, reliable pressure & flow control, pressure relief & safety shutdown systems, gas chromatographs for pipeline gas compositions, and hydrogen fuel regulators for fuel cells.

For OEMs creating solutions in these areas, a few Emerson solutions highlighted above include DeltaV Electronic Marshalling with CHARMs, AVENTICS air prep panels, TESCOM VA and VG series valves, and TESCOM HV-3500 Series Hydrogen onboard regulators.

Visit the Hydrogen Fuel Production and Hydrogen Fuel Cell Manufacturing sections on Emerson.com for more on the technologies and solutions for OEMs in their work with hydrogen producers and distributors.