Digital technologies have advanced the performance of pneumatic systems. In a Tech Briefs article, Smarter Pneumatic Valves Enhance Automation Systems, Emerson’s Marchelle Forish describes how:

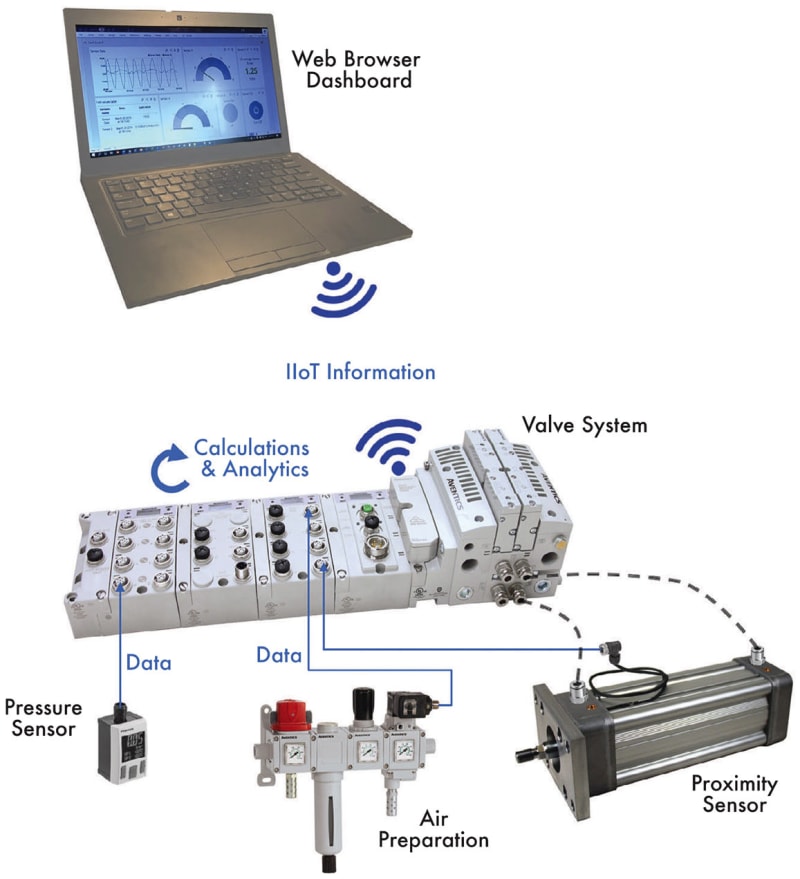

…pneumatic technologies such as control valves continue to evolve, incorporating sensors, industrial network interfaces, wireless technology, and complex digital control features that can significantly improve automation applications through access to smarter, actionable information.

Marchelle describes these advancements:

Marchelle describes these advancements:

As automation systems became more sophisticated, fieldbus (industrial network) communications connectivity became more prevalent. This meant that the PLC could not only control valves but also monitor sensors and devices, exchanging I/O data via one communication cable without needing local I/O cards. Pneumatic valve manifolds naturally began incorporating both fieldbus interfaces and I/O capability to provide complete pneumatic valve packages that were more versatile and engineered to be integrated easily with smarter, more sophisticated automation platforms.

For pneumatic valves, performance gains have come with the:

…integration of electropneumatic control capabilities into the valve manifold. As seen with valve manifolds, strides were also made with proportional regulators. New technologies allowed these devices to be controlled more accurately using digital signals and also allowed the integration of fieldbus connectivity, optimizing force and pressure requirements for the production system.

She shares an example of better welding control in the engine starters.

Here, a pre-mounted armature is transported on workpiece pallets, aligned for position detection, and brought into position for welding by pneumatically driven grippers. After welding, additional grippers return the armatures to workpiece pallets that transport them to the next production step.

Microprocessors enable improved performance.

As pneumatic components become more intelligent, they’re generating additional data points including diagnostics, usage statistics, and lifetime data across the production systems where they’re used. This data is most valuable when used to manage production systems more efficiently, control energy consumption, and maximize uptime.

Read the article for more on how these technologies contribute to digital transformation initiatives, how digital communications enable data to be moved and processed into actionable information, and how these technologies are easily installed, configured and put into productive operation.

Visit the Pneumatic Valves & Control section on Emerson.com for more on the valves and valve systems to drive performance improvements in safety, reliability and efficiency.