Temperature measurement and monitoring is critical to synthesize ammonia for nitrogen fertilizer production. Growers usually use nitrogen-based fertilizers to supplement the soil and improve crop quality and yields. The United States alone consumes 11.8 million tons of nitrogen-based fertilizers annually.

Ammonia (NH3) can be used directly as a fertilizer, or as feedstock to produce other forms of fertilizers such as ammonium nitrate (NH4NO3), urea, and urea ammonium nitrate (UAN) products. Temperature monitoring and control are very important when synthesizing these fertilizers, thus the need for accurate high temperature sensors that can withstand harsh conditions.

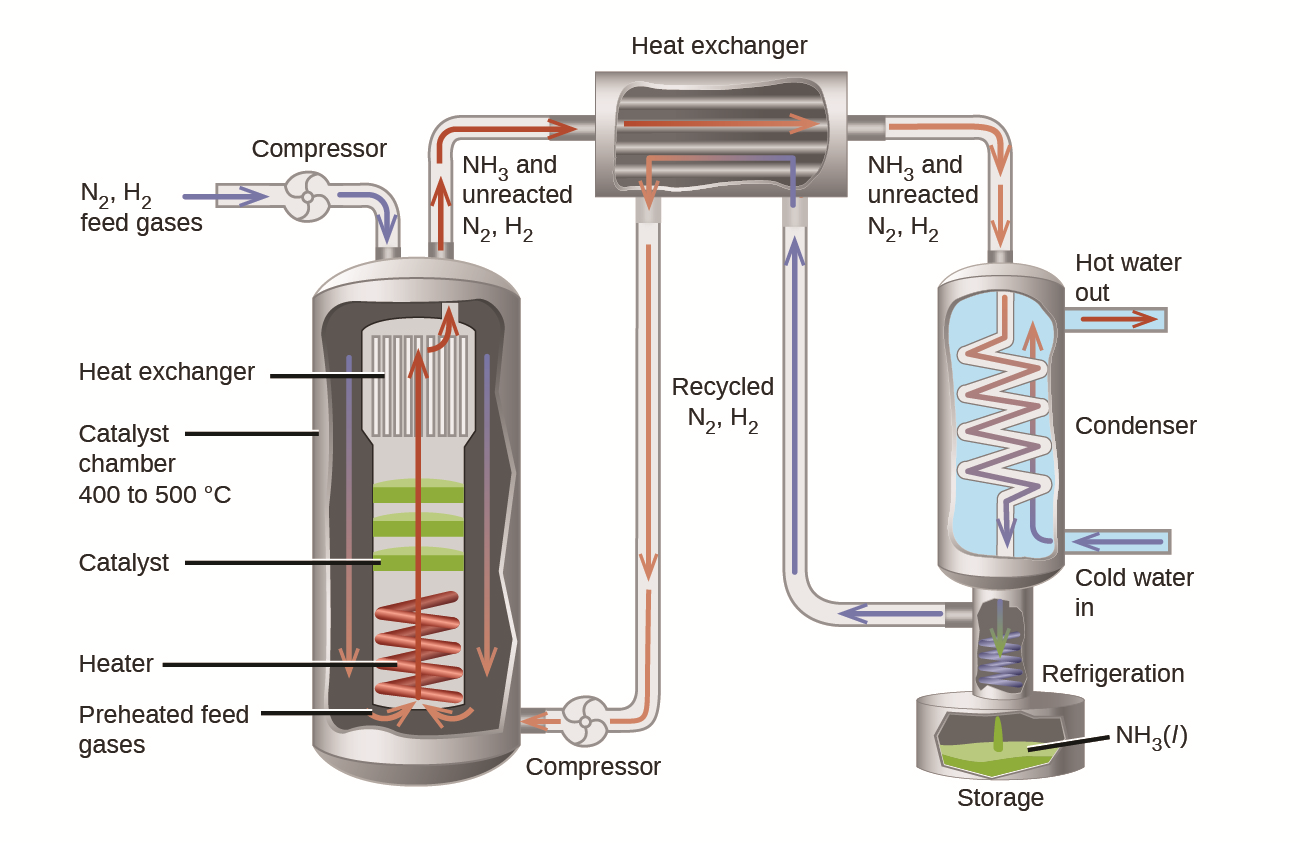

Figure 1: Ammonia production from feed to storage – simplistic view. Click to enlarge

Issues with Safety, Reliability, and Efficiency During Ammonia Production

Figure 2: Ammonia safety sign displayed in a hazardous area at a plant.

The main consideration in an ammonia plant is human safety. NH3 irritates the eyes, nose and throat. It can burn skin, damage lung and/or cause blindness in large concentration. Measurement instruments must be able to endure these conditions as well. Ammonia is highly corrosive and extremely high temperatures are necessary to produce the compound. Over time, both conditions tend to damage standard apparatus, causing them to become defective and the plant to lose its efficiency.

In most ammonia accidents, the hazardous substance occurs in gaseous form. If an injured person is suspected to be in a contaminated area, the rescue effort will be tougher and put to the upmost priority. Respiratory protection, independent of the ambient air, is essential for fire brigades and other emergency personnel. Other important safety wears include helmets and goggles which protect the eyes from contact with the contaminated atmosphere at the same time. In many cases, gas-tight chemical protective suits are required in the expected hazardous situation. If liquid ammonia leaks from the refrigeration systems, the situation will become more problematic. Upon contact with the skin, the temperature of the liquid, which is -33 °C or lower, will cause frostbite. The severity level depends on the contact surface and the amount. Even with basic protective clothing, it cannot withstand the freezing cold liquid that corrodes through the material. It is recommended to wear chemical protective suits, made from cold-resistant material, when starting the work. To protect the skin from frostbite, warming work clothes as well as woolen sock liners and finger gloves should be worn under the suit. The associated dangers, downtime and costs can be detrimental.

How the Skin Temperature evolved to non-intrusive Temperature measurement?

In the past, skin temperature measurements cannot be relied as accurate predictor of process temperature due to the impact of the environment and heat loss. The physics of heat transfer through the pipe and variations in ambient conditions have to be considered as they have significant impact to the measurement accuracy. Rosemount X-well technology made it possible to model in real-time with the physics of heat conduction through the pipe as well as compensate for variations in ambient temperature—and do all that within the transmitter itself.

Rosemount X-well technology is based on Emerson’s industry-leading Rosemount 3144P analog/HART and Rosemount 648 wireless temperature transmitters. Notably, when intended for use, the transmitter’s firmware comes with factory configuration that include the pipe’s material of construction, diameter, and schedule to accurately model heat flow from the process to the outer surface of the pipe. Meanwhile, the effects of changes in ambient temperature are compensated based on the temperature reading of a second, high-accuracy RTD within the transmitter housing.

The Customer Challenge

In this case study,Emerson examines the challenge faced by a chemical customer in Asia. This solution was provided for a manufacturer and distributor of diversified chemical products (e.g., monoammonium phosphate, phosphoric acid, sulphuric acid, synthetic ammonia, phosphatic compound fertilizers) based out of Yunnan, China.

In the customer’s plant, ammonia flowed through the pipeline in the ammonia production unit in liquid form. A traditional patch sensor installed on the pipeline was used to measure the temperature and data was then transmitted to the distributed control system (DCS). Temperature readouts range from 0 °C to 200 °C. Low level sensor signals from RTDs and Thermocouples are quite susceptible to Electromagnetic Interference (EMI), electrostatic Discharge (ESD) and Radio Frequency Interference (RFI).

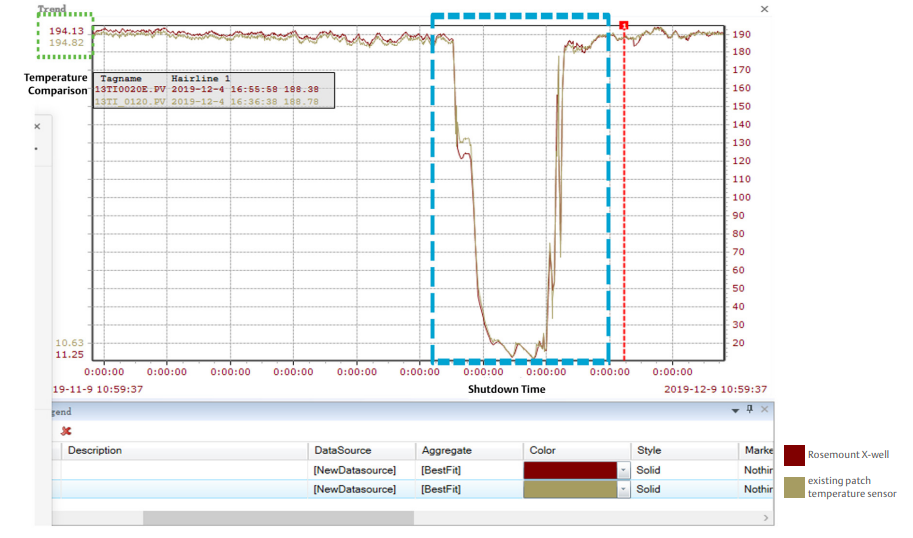

Sensor leak can act like an antenna for noise interference causing a potential wide range measurement error. The system installed in the temperature loop suffered from large static compensation error resulting in inaccurate measurement readings at the control system. These inaccuracies also pose safety risks in the process unit. To prevent hazard, the management instituted a plant-wide policy to ensure that the readings on the ammonia pipeline is highly accurate. The challenge is to minimize temperature reading errors below its current range of +/- 1% of span.

Figure 4: A side-by-side comparison of the Rosemount X-well showing marked performance improvement at the DCS versus existing patch temperature sensor as evidenced by decreased noise/error and smoother curve. Click to enlarge

The Emerson Solution

Emerson recommended Rosemount X-well Technology with Rosemount 3144P Temperature Transmitter to improve measurement accuracy and reduce safety risks due to errors in readings. This provides a complete point solution for accurately measuring process temperature without the need for a thermowell or process penetration. Rosemount X-well Technology calculates a repeatable and accurate process temperature measurement via an in-transmitter thermal conductivity algorithm. With simple clamp design, pipeline modifications, hole drilling, welding and fixture insert are not required.

With the Rosemount X-well Technology, customer can get accurate and quick temperature readouts from the DCS, enabling effective Hazard and Operability Analysis (HAZOP) for the liquid ammonia pipeline over an extended period. There is no need to stop the equipment and maintain the sensors. The Rosemount X-well Technology is also SIL3 Capable: IEC 61508 certified by an accredited third-party agency for use in safety instrumented systems up to SIL3.

Overall, customer can realize the benefits of more accurate and quicker temperature readouts while improving safety and reducing maintenance hours.

Rosemount X-well technology is available in wired and wireless models with transmitter finishes in durable enamel or stainless steel.

What Other applications are most suitable for X-Well technology?

Applications suitable for Rosemount X-well technology range from monitoring pipelines to small line-size applications. Obviating the need for a thermowell is especially advantageous for pipes that require frequent cleaning, high velocity processes, slurries and heavy particulate fluids, clean-in-place processes, high viscosity fluids and harsh processes requiring exotic thermowell materials.

Retrofit or incremental temperature measurement applications are particularly attractive because no process penetration or associated production interruption is necessary. The value proposition of Rosemount X-well technology, embedded with Wireless capabilities is even more compelling since there is no need to run cable either. This makes it particularly useful for diagnostically driven implementations.

The elimination of thermowells also reduces the associated leak points and long-term maintenance requirements. From an engineering perspective, wake frequency calculations are eliminated, as is the time spent determining the material compatibility, correcting the insertion length and thermowell profiles. The result is a 65% savings in engineering time and effort.

Furthermore, Rosemount X-well technology can be installed with standard pipe-clamp procedures and ordinary hand tools. It does not require a welder or pipefitter, resulting in a 70% savings in installation costs. In any installation, at least half an inch of insulation over the skin sensor, should always be used to meet performance expectations.

Emerson continues to invest and improve on the technology’s capabilities over time, but non-invasive methods in general are not suitable for processes with rapidly changing conditions, such as safety loops, custody transfer or fast control applications. Low fluid velocities and non-metallic pipes are also not suitable. There are far more applications in which Rosemount X-well technology is suitable and it definitely outweigh the benefits of using it.

Visit the Rosemount X-well Technology section on Emerson.com to learn more about how Rosemount X-well technology provides accurate temperature measurements without the complexities of thermowell assembly.