You may or may not have seen the news from the recent Emerson Exchange conference, Emerson Unveils Architecture Vision for ‘Boundless Automation’.

You may or may not have seen the news from the recent Emerson Exchange conference, Emerson Unveils Architecture Vision for ‘Boundless Automation’.

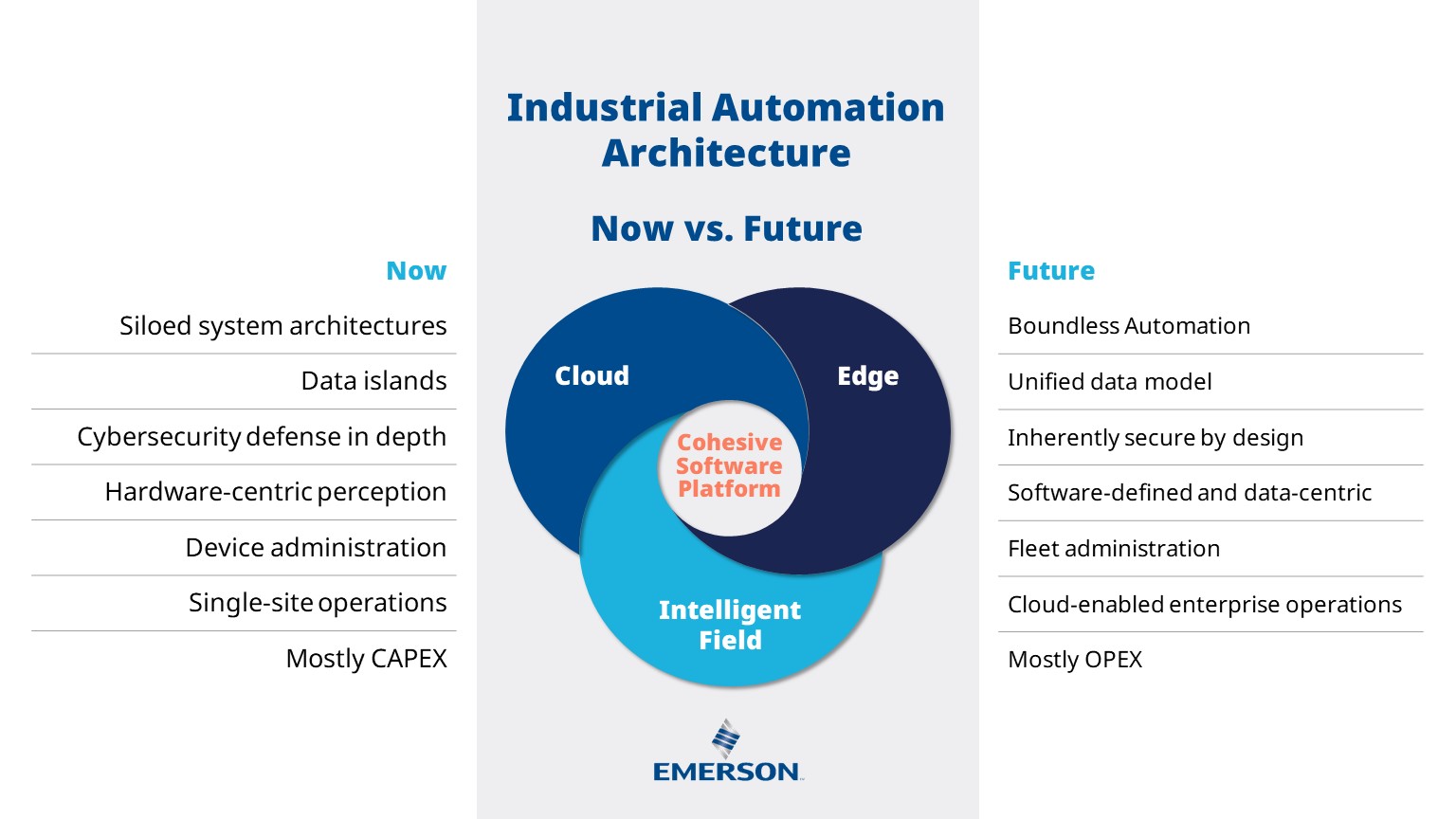

This next-generation architecture will empower companies through “boundless automation” to manage, connect and deliver operational technology (OT) and information technology (IT) data seamlessly and easily across the enterprise. Moving data freely and securely across OT and IT domains – from the intelligent field to the edge and cloud – will enable operational and business performance optimization across the enterprise.

A vital part of this architecture is the AspenTech software applications. I’ll highlight one example, APM 4.0, from the ITP.net article, How AspenTech is ushering the oil and gas sector to sustainable operations with APM 4.0. AspenTech’s Mike Brooks shares how this portfolio of applications helps companies use their massive amounts of data to improve operational sustainability.

APM 4.0:

…encompasses more than just routine maintenance of mechanical equipment and preventing unscheduled downtime. In order to increase asset dependability and extend asset life, this strategy integrates Industry 4.0 technology with recommended maintenance procedures. To properly support the business objectives of any manufacturer.

Asset performance management (APM) relies heavily on technologies like condition-based monitoring and product inspections, which can be supplemented and enhanced by new technologies and not completely replaced. Hence, it is of utmost importance to not implement new technologies without proper strategies and goals.

The article quotes Mike on the importance of starting with business objectives.

“Often times, we talk about initiatives, like big data, digital transformation, etc. But they aren’t real initiatives, they are tools to accomplish an initiative. Initiatives might be operational excellence, improved product quality, longer lifespan of equipment etc. It is important for business to realise the initiatives and then decide on the tools for digital transformation. Businesses should steer away from implementing technologies for technology sake…”

Using APM 4.0 can change a cost-based mindset to a performance-based mindset.

Implementing APM 4.0 changes the asset from being merely a cost centre to a major driver of profitability. APM 4.0 drives insights and innovations for operational excellence. Machine maintenance, unplanned downtime and the likes make an impact on the cost. These unforeseen events can be navigated through with APM 4.0.

Here are the applications within the APM 4.0 portfolio.

- Aspen Mtell uses pioneering machine learning-based pattern recognition to measure normal plant operating performance and to detect anomalies and precise failure signatures that link root cause and failure modes. It dispatches early warnings and correction/mitigation advice weeks and months in advance of impending degradation and failures.

- Aspen ProMV learns the correct operational strategy from AI analysis of archived data and then continuously monitors and advises when and precisely how to adjust to keep yield and quality on track.

- Aspen Fidelis assesses the cost and risks of any decisions made on operational availability and performance that limit production for capital and operational expenditure situations.

- Aspen Event Analytics for operators detects “not okay” conditions and dispatches advice for quick corrections, ensuring nothing spirals out of control. It is an easy-to-use tool with self-service analytical heavy-lifting built-in and automated shape recognition to identify and visually correlate trends that matter.

Read the article for more on how this application delivers insights beyond a single asset to identify performance improvement opportunities. Follow some of the links above for more on the applications in APM 4.0.