Renewable diesel, also known as green diesel, is an advancement over traditional biodiesel. Unlike biodiesel which needs to be blended in small quantities with conventional petroleum-based diesel, green diesel is fully compatible and can be distributed using the established petroleum logistics systems.

At a recent Green Innovation Day meeting in the Houston, Texas, area, Emerson’s Julie Valentine presented ways to make investments in green diesel production evergreen and improve the financial performance of this process. Julie opened her talk by sharing the renewable diesel opportunities across North America. She showed a map and chart with 6.6 billion gallons produced annually in the United States. 12% of this total is currently operational, 24% is under construction, 26% is an expansion to existing production, and 39% is proposed capital spending. California and Louisiana lead the states in current output.

Three areas where improvements can be made include the pre-treatment, reactor, and offsites sections. In the pre-treatment area, the opportunity is to ensure the elimination of contaminants and protect catalysts downstream and design the process to treat multiple feedstocks and adapt to future feedstocks. In the reactor section, the opportunity is to accurately calculate mass and energy balances even when using variable feedstocks by:

- Controlling the exothermic reaction through varying feedstock quality conditions

- Monitoring catalyst deactivation

- Corrosion monitoring

- Hydrogen demand

- Recycle gas loop analysis

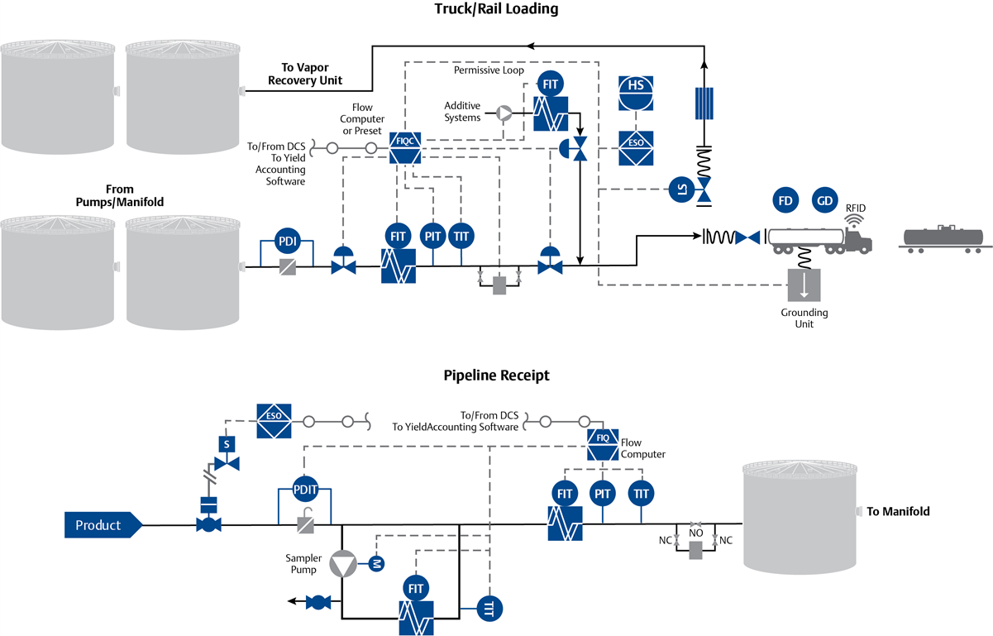

In the offsites area, the opportunity is to improve the safe and efficient transfer of feedstocks and products through the supply chain. It is vital to measure all materials, yields accurately, and utilities consumption to obtain renewable credits.

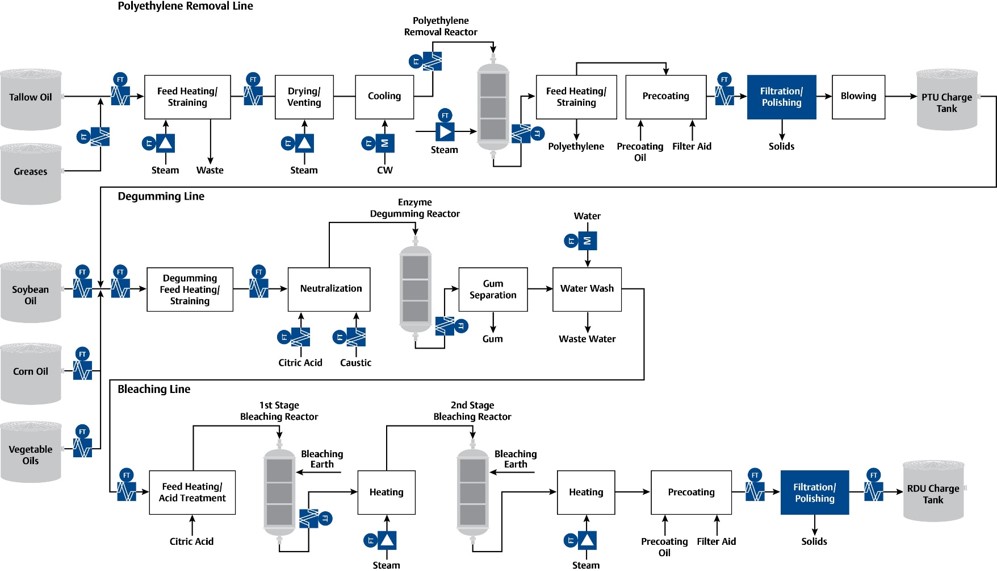

The pre-treatment section eliminates contaminants that can poison catalysts in the reactor section. Accurate measurements ensure the effectiveness of pre-treatment, and the mass balance is a tool used to evaluate operational effectiveness. In particular, the mass balance around the degumming reactors can help control yield loss. Not only are the measurements necessary for mass balance but also for process control, neutralization control, filtration, corrosion monitoring, steam measurement, and utilities measurement.

Some necessary measurement devices include Coriolis mass flow measurement meters, inline and wireless corrosion monitors, turbidity and pH meters, differential pressure (DP) measurements across filters, guided wave radar level measurements to handle specific gravity and viscosity changes, magnetic flow meters for acid & water flows, and equipment asset monitoring software.

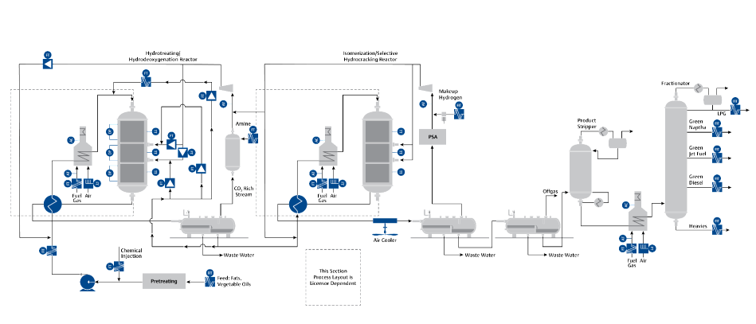

In the reactor section of the process, critical measurements for control and optimization include mass balance meters, HDO reactor exothermic temperature monitoring, HDO reactor fresh feed to recycle ratio for temperature control, H2/HC ratio control for both the HDO and isomerization reactors, DP across catalyst bed to monitor coking/deactivation rates, fired heater energy optimization, accurate chemical injection to maintain the required environment for the reaction, heat exchanger/fin-fan monitoring to identify fouling conditions, and corrosion monitoring in the air coolers, separators, and overhead condensers.

Coriolis meters improve mass balances and combustion optimization. Quad vortex meters provide accurate reactor control for the target feed to recycle ratio and hydrogen purge. Highly accurate temperature transmitters are used in cascade control of the recycle oil and hydrogen quench flows. DP transmitters with Electronic Remote Seals (ERS) provide highly accurate and reliable reactor bed measurement of contaminant or coke buildup on the catalyst. Measuring hydrogen purity with continuous gas analyzers optimizes catalyst life and reactor sour environment control. Electrical Resistance (ER) or Electrochemical (LPR) probes and analytics software provide inline monitoring of the downstream flows to the wastewater system high in corrosive carbon acid. Wireless ultrasonic sensors and analytics software monitoring pipe wall thickness.

Since the reactor section is the most critical unit for business performance gains, valves play a key role in maintaining safe and reliable operations. Given the corrosive process conditions, standard and severe-service control valves with higher alloy content such as 347 or 625 metal alloy materials are often required. Digital valve controllers provide tight control and predictive maintenance to extend reliable performance. The separator letdown valve, hydrogen quench valve, hydrogen compressor discharge overpressure protection, compressor anti-surge, automated isolation valves, and fuel gas header regulator are applications for these valves.

Finally, in the offsites area, selecting high-performing technologies that can measure multiple feedstocks and products while complying with custody transfer standards is essential for billing, loss control, and obtaining government subsidies. Important technologies include analytical & corrosion monitoring, asset monitoring, automatic tank gauging systems, custody transfer metering & yield accounting, and loading & unloading solutions.

Visit the Sustainability section on Emerson.com and some links throughout the post to learn more about specific technologies and solutions to drive renewable diesel production and distribution performance improvements.