Air Liquide’s Craig Spivey, Emerson’s Tinh Phan, and Emerson Impact Partner Puffer-Sweiven’s Salim Jaffer presented Air Liquide Launches an Initiative Around AMS Device Manager at the 2023 Emerson Exchange Immerse Conference. Here is their session’s abstract.

Three years ago, Air Liquide was introduced to the immense power of AMS Device Manager by deploying Smart Commissioning. The project did not go as planned since the contractor employed and the engineering staff responsible for the project were not well informed about the product. Air Liquide ended up not using AMS Device Manager for subsequent projects. This opened an opportunity to launch various Emerson Education engagements for I&C staff at Air Liquide. Customized training at two skill levels was deployed. In two years, the employees’ knowledge base was raised to a level that it became a corporate initiative. Every outage and every upgrade heavily used the power of AMS Device Manager. Today, Air Liquide has 10,000 tags in the US alone.

Craig opened the presentation by sharing their story, beginning with a proof of concept. They wanted to use smart commissioning. They started with an engineering firm, but things did not work out. They decided they needed to work internally and emphasize the work processes.

In the proof of concept for documentation, they prepared a master list of all HART-related devices, including device type, model, and revision. They ordered devices with HART tags configured and defined master templates for transmitters and positioners.

DeltaV with I/O Studio was used to define the auto-commissioning policy. Using the bulk editor, they updated the readback path, scale, and templates for transmitters and valves. They defined HART_ERROR and Remove PV filters for testing.

AMS Device Manager was used to bulk edit instrumentation using templates. It was essential to create a standard early and prepare by having valve spec sheets so AMS / ValveLink has the correct information. They used online and offline diagnostics immediately when installing an intelligent positioner.

Air Liquide created a focus group consisting of control engineers and advanced instrumentation technicians with the scope to consider workflows, actions to alert, how to integrate daily, and the education level of software and HART alerts.

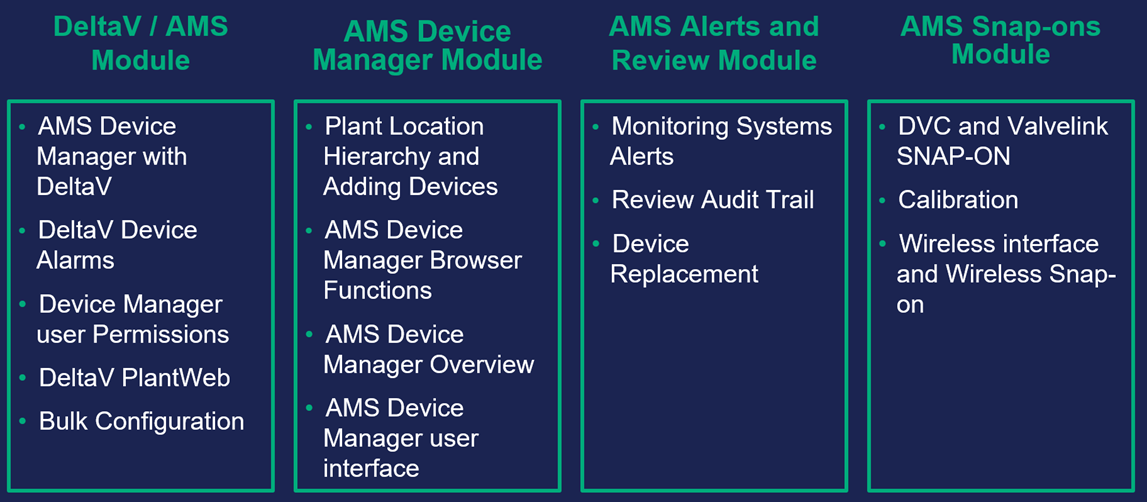

The education program for the engineers and technicians consisted of several key areas.

Tinh shared how AMS Device Manager enabled configuration management, diagnostics and monitoring, and calibration management as a foundation. Connectivity is available to many third-party control and safety systems.

For their site, they monitor over 10,000 devices. Reports are generated and brought into the technicians’ workflow. This information has improved overall knowledge of their instrumentation, giving a picture of the health of the instruments and simplified troubleshooting.

With the Fisher digital valve controllers and the ValveLink Snap-on, they can instantly spot issues with valves and actuators. A batch for data collection and review was created with reports viewed by the maintenance staff bi-weekly. With this information, informed decisions based on current data could be made on what valves and instruments need attention.

With smart commissioning, their practice is to purchase preconfigured transmitters and positioners with defined templates created for the DeltaV system. This approach saved weeks of commissioning time, with no lost time moving between instruments. Cost savings came from technicians’ time, engineering verification, and an earlier startup.

As part of future control system modernization projects, all smart transmitters and smart positioners of critical valves will be included using the smart commissioning approach in the project phase and the reports for ongoing optimized maintenance practices.