As Claudio Fayad explains in his recent article in Processing magazine, there are many exciting changes coming as Emerson embarks on its Boundless Automation™ journey and evolves the modern control system in to a next-generation automation platform. However, what might come as a surprise is that many of the coming evolutions will look familiar, as quite a bit of the important work is based in a decoupling journey—one that actually started a long time ago.

More freedom for I/O

People who have been in the automation industry a long time likely still remember the days when I/O required termination on marshalling cabinets and I/O cards attached to the controller. The complicated interface meant project engineering was extremely complex—wiring diagrams needed to be created in advance of every project and though they could be changed later in the project, those changes could quickly become very costly.

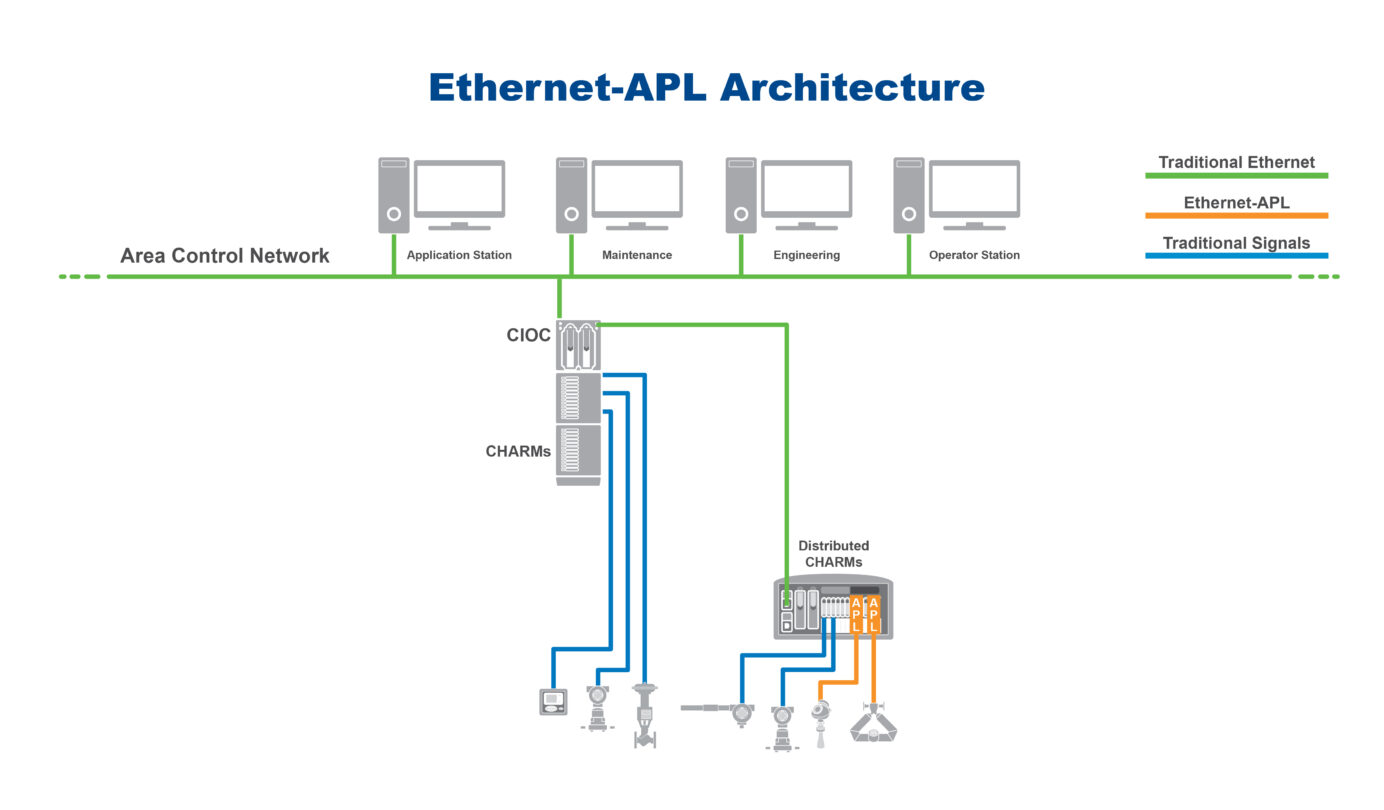

To meet this need, Emerson designed an Electronic Marshalling solution. Electronic Marshalling decoupled I/O from the controller, empowering teams to define I/O on an as-needed basis and gave them the option to stay flexible even in the late stages of a project. And while that critical transformation took place decades ago, the decoupling of I/O from the control system is still relevant in one of the newest technologies that will form the foundation of the Boundless Automation journey: advanced physical layer (APL). APL brings the power and flexibility of Ethernet into the plant using the two-wire cabling that plants already have in place. As Claudio explains, using APL to further decouple I/O from the control system will bring big benefits,

“Driven by Ethernet equivalents of today’s protocols—HART-IP, PROFINET, Ethernet IP, and more—the I/O system will become smarter, and the use of APL will make it easier to install and maintain these networks. These new I/O networks will support high-bandwidth technologies to bring many more devices, and far more data types, into the control system and cloud analytics systems.”

Ethernet-APL unlocks high-bandwidth technologies to bring many more devices, and far more data types, into the automation platform.

Fewer hardware constraints

Process manufacturing plants can often be rough environments for electronics—but maybe not as often as people think. Emerson estimates that today, only 20%-25% of controller installations need hardware designed around robustness. The majority are actually running in clean cabinets in climate-controlled environments. That’s why Emerson is moving away from a hardware-centric vision for control, and beginning to decouple the control software from its hardware, providing users far more options.

Solutions like Emerson’s DeltaV™ PK Flex Controller are moving away from a hardware-centric vision of control design. The PK Flex Controller offers added flexible and scalable capacity through a subscription-based license. Users can subscribe only to what they need and can add functionality over time. But that’s only the start. Claudio goes on to explain how hyperconverged infrastructure will change the paradigm for automation technologies,

“With the evolution of hypervisors, hyperconverged infrastructure, containers, and workload orchestration, automation suppliers will have the tools they need to host deterministic, ultra-low latency, real-time control on appropriate hyperconverged platforms. OT teams will gain even more ability to make the best decisions about the hardware and software they want to use for their environment by mixing real-time workloads with non-real-time workloads. This will allow these systems to benefit from virtualization, cloud connectivity, increased data mobility, lower IT infrastructure and maintenance costs, and more.”

Everything you need, where you need it

Decoupling IO and software are only the beginning. New automation technologies like the DeltaV Edge Environment are decoupling data as well, helping multi-disciplinary teams innovate by bringing contextualized data from the control system into a testing sandbox where they can develop and run applications. The DeltaV Edge Environment also makes it easier to move critical data into the cloud applications for enterprise-wide analytics and to train the artificial intelligence engines that are defining the future of technology.

Ready to learn more about the future of automation? Read Claudio’s article in full over at Processing magazine.