Plant and worker safety is a priority for the process industries. Moazzam Shamsi, FREng, Director, Global Solutions Architect, explains how Emerson’s Location Awareness system enhances personnel safety operations, reducing complexity and costs compared to existing solutions.

According to the International Labour Organization, each year 2.78 million people die as a result of occupational accidents or work-related diseases. In addition, there are around 374 million non-fatal work-related injuries and illnesses per year and the annual cost of poor occupational health and safety practices is estimated at 3.94 percent of global gross domestic product. Refineries, chemical plants, oil rigs and power plants can be particularly hazardous environments and the companies that operate them are therefore continually striving to optimise the safety of their personnel.

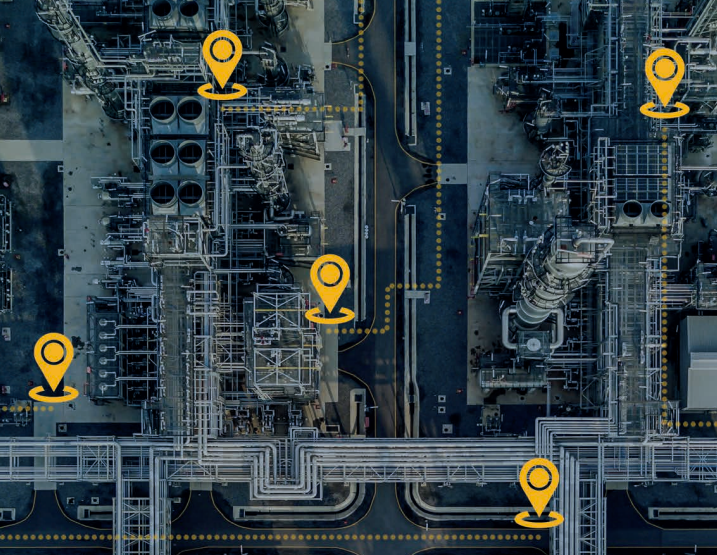

In an emergency, when every second is crucial, the priority is to locate and ensure the safety of all personnel on-site. Therefore, when companies formulate a personnel safety plan, it ought to include an ability to pinpoint the whereabouts of workers in such situations, as well as a reliable means of getting help to them quickly should it be required. Technological advances have led to the creation of real-time personnel location systems that can achieve these aims. However, the cost and complexity involved in installing and maintaining solutions of this kind has proved a major obstacle for many companies.

Emerson’s Location Awareness personnel location system helps to overcome this problem. Location Awareness is an accurate, reliable and easy-to-install real-time personnel location system that enables industrial companies to enhance their safety operations for less than half the cost of existing solutions and with installation times reduced from weeks to just days. Consisting of several different technology layers, Location Awareness combines a new software application in Emerson’s Plantweb Insight industrial analytics solution, with proven and secure industrial wireless infrastructure and rechargeable personnel tags that transmit real-time location data.

The scalable Location Awareness system includes a safety-mustering feature that provides real-time visibility by showing which employees have or have not checked in at their designated muster points during either drills or an actual emergency. It also includes man-down alerts, where personnel that have been injured in a dangerous location can push a button to send an alert with their location, enabling emergency response teams to be dispatched to their assistance as quickly as possible. Helping to keep up to 10,000 workers safe, a geofencing and monitoring feature within the system establishes a designated work zone, or geofence, around a group of personnel or contractors and provides alerts when someone ventures outside the zone. It also creates zones for known hazardous locations.

The system’s personnel tags have a battery life of over two months and can be recharged in only two hours, thereby minimising maintenance needs. They are certified for use in very hazardous areas, and can be easily worn on lanyards, belt clips or other such accessories.

“Digitally transform safety operations for less than half the cost of existing solutions, with installation times reduced from weeks to just days.”

A high level of reliability is assured for the Location Awareness solution as it uses WirelessHART® infrastructure, proven in use with over 12 billion operating hours at tens of thousands of plants and facilities worldwide. Should WirelessHART® infrastructure already exist at your plant, this enables even greater cost and installation time savings to be made compared with implementing alternative solutions. Many competing services require extensive power wiring to their wireless infrastructure components, but Location Awareness does not because most of the components have their own power source.

A high level of reliability is assured for the Location Awareness solution as it uses WirelessHART® infrastructure, proven in use with over 12 billion operating hours at tens of thousands of plants and facilities worldwide. Should WirelessHART® infrastructure already exist at your plant, this enables even greater cost and installation time savings to be made compared with implementing alternative solutions. Many competing services require extensive power wiring to their wireless infrastructure components, but Location Awareness does not because most of the components have their own power source.

Learn more about how the Location Awareness system can safeguard your company’s workforce.

Read the entire Innovations in Automation Issue 15 “Digital transformation is revolutionising your plant performance”