(First in a series)

(First in a series)

In industrial plants, probably more than any other enterprise today, the skills gap created by the retirement of old-line experts and the challenge of hiring means that having enough trained and informed people to get the job done is a daily problem. At the same time, the pressure to increase or at least maintain profitability/viability doesn’t decrease, although budgets may. The critical nature of operations makes industry risk-averse, slow to change and every expenditure has to justify itself many times over.

Still, the only way to balance the lack of expert personnel and the need for profitability is an increase in productivity and a decrease in downtime that can only be achieved through technology. But, by definition, that technology has to solve problems and pay for itself from day one.

Unexpectedly enough, that’s where augmented reality comes in.

Today, industry professionals are realizing that a technology that once only existed in gaming is the most practical, highest ROI tool that they can consider. Augmented reality (AR) tools can help close the knowledge gap, connecting less-experienced personnel to vital information and experienced mentors while they work – rapidly upskilling a new generation of operators and technicians and ultimately enhancing productivity and the bottom line.

Imagine that you have a large plant with hundreds of disparate assets and a maintenance team, many of whom are new and not yet fully trained to recognize and fix problems with each of these assets. The maintenance tech may need to consult a central location or a distant workstation to get access to the key performance indicators on that machine and the experts may not be available to support them.

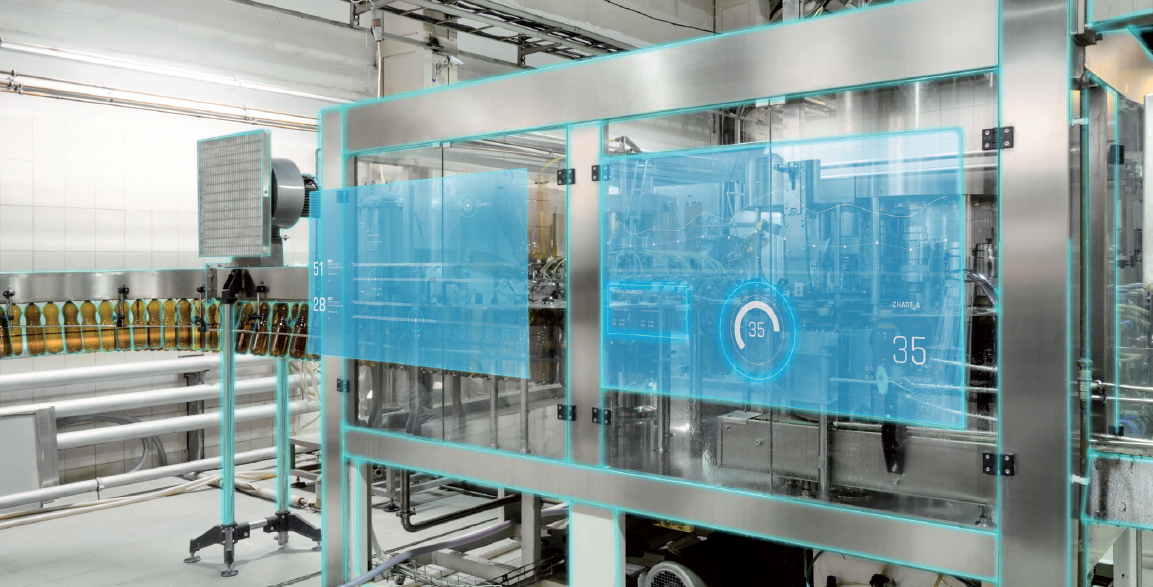

Now imagine maintenance personnel on duty carry tablets that enable them to walk to a machine and see KPIs superimposed over the asset to help them with equipment inspection and overhaul. With this information, they can evaluate if the machine is performing optimally according to specifications or if any action is needed.

Maintenance staff may approach a group of machines that are inaccessible, whether they are behind a gate or too high to reach. Traditionally, they would have to obtain permission to access the machine and cause a temporary process shutdown to view the current performance indicators and determine the correct course of action. However, with augmented reality, the maintenance technician can simply hold up a tablet and zoom in on the machine and all of the status indicator information is instantly available without having to open a gate or cause any interruption in service.

This is a very simple example of what augmented reality can do, not in the future, but today.

AR is suitable for both the manufacturing and process industries, allowing operators to use technology integrated with standard IIoT, SCADA/HMI, and plant analytics tools to perform actions needed within various production stages.

Wearable and mixed reality AR devices supplied to operators can come in a kit that includes glasses or helmets fitted with displays, cameras, audio hardware and Wi-Fi connectivity that maximize flexibility. More frequently, mobile devices are carried by operators walking through the plant. Although AR systems will tend to be complementary solutions, rather than completely replacing workstations that support traditional work processes, the mobile nature of these devices reduces costs and provides much greater flexibility and speed during operational phases.

Emerson is one of the first companies to offer AR solutions for SCADA/HMI, providing operators and plant floor/field workers with immediate access to a wealth of data by means of mobile and wearable AR devices. AR is integrated into the Emerson Movicon.NExT™ SCADA/HMI platform, which translates to easier, less costly implementation and a faster return on investment.

A new-generation SCADA/HMI platform, the Emerson Movicon.NExT platform is a modular software solution, centered on a .NET framework, that has been developed by Emerson specifically for automation applications on PC-based architectures and embedded systems. It is one of the few products that fully operates on both Linux and Windows including protocol drivers. Movicon.NExT uses the OPC UA data transfer specification as the backbone for communication between client applications and industrial data. This creates the ideal solution for IIoT projects, which need to be inherently open and flexible.

To learn more about this exciting new AR solution, check out the complete white paper from which this blog is excerpted and watch for the follow-on blog that will cover future applications of AR in industrial plants and enterprises.

And click here to read the second blog in this series.