Some of the greatest performance, investment, and eco-sustainability gains for any operating or manufacturing company are found by optimizing the consumption of resources and energy, including water, air, gas electricity, and steam (WAGES).

In my October CFPA article, titled Use a Powerful Digital Platform for Optimizing WAGES, I examine how choosing the right digital transformation hardware and software platform can accelerate companies into the future with improved efficiency, quality, and sustainability, at all scales.

Accessing all the data

Many companies struggle to get WAGES under control because the source data is stranded in many very different systems. Whether they are trying to connect with a single machine—or to site-wide systems such as a building management system (BMS), HVAC, lighting, production lines, intelligent power systems, or more—an open and scalable digital energy management platform is needed to deliver complete WAGES visualization and value.

Gathering data is just the first step, and traditional HMI/SCADA has been very useful for this task in the past. But a true energy management system also needs to incorporate analytical tools, along with dashboarding, trending, and other data displays attuned to WAGES supply and consumption.

Users should be able to create and access tabular, multi-trends, pie chart, and other styles of reports showing consumption for a given time period, with the ability to compare information for different time periods. When evaluating consumption, users will want the ability to drill down to individual equipment, or expand up to groups of equipment, as they investigate usage.

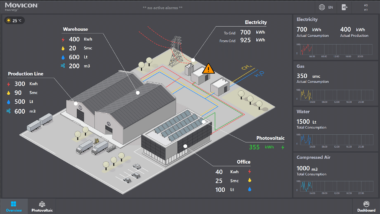

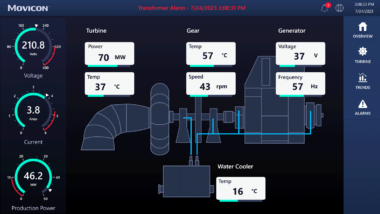

Emerson offers a suite of software products to address these and other WAGES issues. Movicon.NExT™ HMI/SCADA delivers clear and effective visualization for operators, whether they are located on the plant floor, in the control room, at the enterprise level, or remotely via mobile devices.

The Pro.Energy© software module is an open solution which adds WAGES-specific intuitive interfaces to Movicon.NExT, enabling real-time monitoring of energy consumption to support achievement of efficiency and sustainability goals. Connext© communications software includes all major drivers—OPC UA, Modbus RTU and TCP, BACnet/IP, MQTT, IEC 61850, EtherNet/IP, PROFINET, and many more—to enable seamless communications among all facility equipment, supporting a complete Floor to Cloud™ communications architecture.

One manufacturing site used these products to manage their BMS, including water and gas meters, 15 other energy meters, four HVAC units, and three lighting units, with plenty of capability to expand in the future. The software creates energy performance indicators (EnPIs), which are metrics supporting analytics driving the reduction and elimination of waste, and it displays these on convenient dashboards.

Modern HMI/SCADA software, in conjunction with a capable communications server and an energy-specific software extension is available, empowering users to rapidly create a complete digital energy management platform. Using these open and proven software products, which are supplied with wizards and libraries, enables companies to realize a step change in efficiency and sustainability.

Visit the Movicon HMI/SCADA sections on www.Emerson.com for more information about creating a digital energy management platform for optimizing WAGES.