If you were to ask most people in the chemical processing industry about the kinds of steps necessary to support sustainability efforts, you’d likely get a variety of complex answers citing alternate energy sources, rethinking supply chains, and suggesting major changes to processes. These may all be valid, but let’s suggest something very practical, and doable right now: tightening up plant maintenance efforts. Here’s another: small but strategic upgrades to instrumentation for combustion management.

These may not sound very exciting for something as consequential as sustainability, but they are easy to implement, make a big difference, and are often self-supporting from a cost standpoint. Looking at how these ideas work is the main thrust of our article in the July issue of Chemical Engineering magazine, Reducing Emissions for Sustainable Manufacturing. So why is maintenance so important? Because when it’s done incorrectly, facilities waste energy and increase emissions, as we point out:

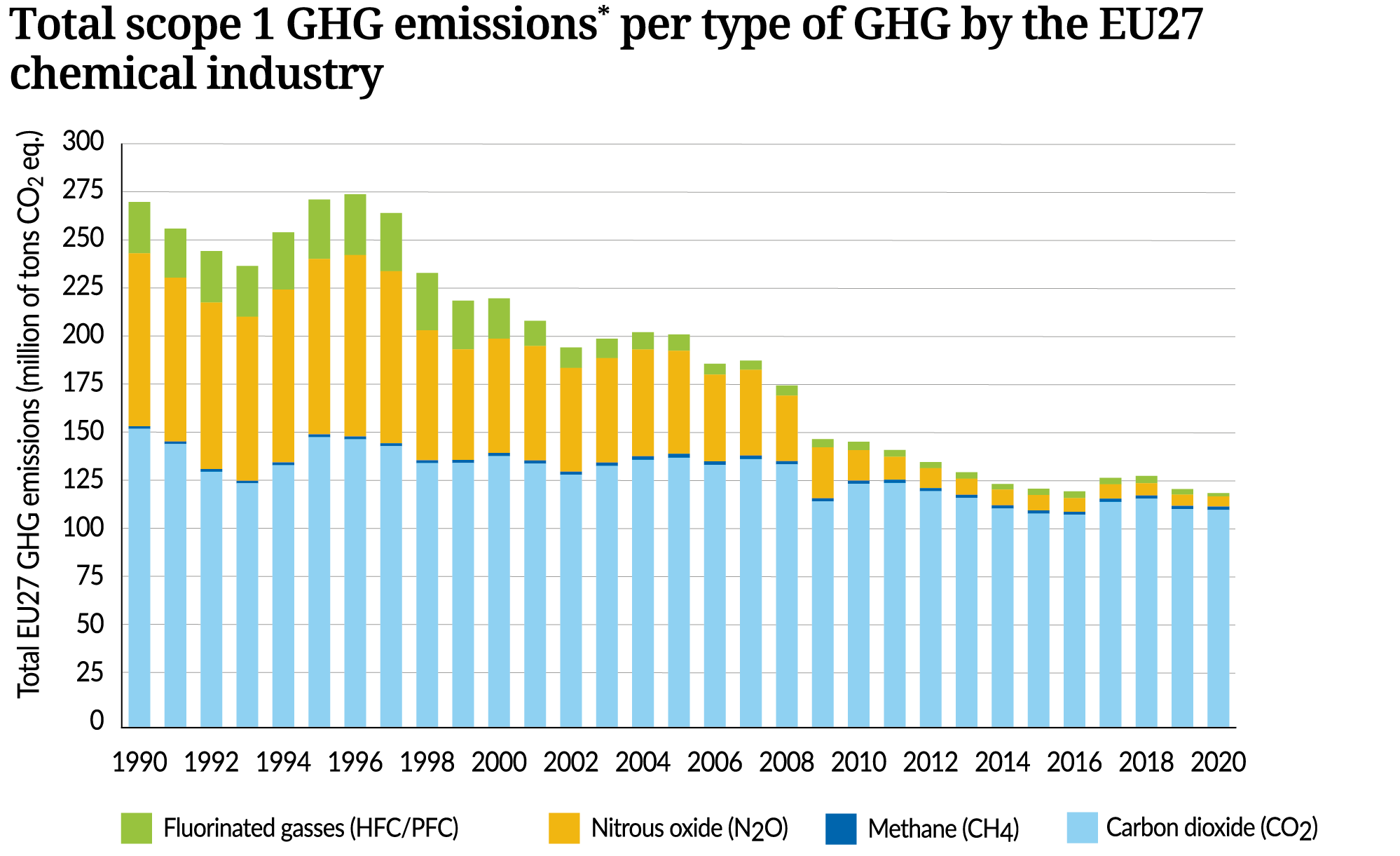

There are countless smaller efforts that can be made to tighten up operations. Each of these projects are modest in scale and cost, but they will result in a significant cumulative reduction of overall emissions. Since they can be applied selectively, it is possible to aim directly at bad actors in a facility, delivering the biggest bang-for-the-buck early in a program. These solutions use conventional technologies and can even be self-supporting financially because they save money as they reduce emissions.

The latter point is the key, and we created a detailed list of areas to examine to find where those “smaller efforts” can be most effective. For example:

- Process units invariably give up process liquid or gas from two primary areas: process valves, either control or on-off; and pressure relief valves. The design should then be robust, electrified if possible and detection technologies should be leveraged. Many things to include in regular maintenance and upgrade plans.

- Fuel variability is a common enough problem that the American Petroleum Institute (API) established a subcommittee that explored its effects. It examined the problem using an independent software tool, developed to assess the impact such variable BTU content can have on production costs if compensating adjustments are not made in real-time. A Coriolis flow meter measures mass, so it detects such changes in real-time, making fuel flow more closely reflect energy flow.

- Another critical measurement is made by an O2 sensor, used to determine if the mixture of air and fuel is optimal. A 2% increase of O2 in the stack can increase emissions between 25-30%.

- It is common for steam generation to account for 40% to 50% of a facility’s entire energy budget, so efficiency changes, for better or worse, can cause a substantial difference to the bottom line, and to emissions.

You get the idea, and there are many more possibilities examined in the article. They are all common in the chemical processing industry, and each is surprisingly easy to solve with a few improvements built around Emerson products. These upgrades will make a significant difference, and most will save you money in the process.

Visit the Emerson.com Chemical content. You can also connect and interact with other engineers in the Chemical Processing Group at the Emerson Exchange 365 community.