At the 2024 Ovation Users Conference, Emerson’s Matt Cimino presented What’s New in PID Algorithm Enhancements. Here’s his presentation abstract.

The PID algorithm has had newly added features to allow for better control over processes. During the session, the new enhancements will be shown and how they can be used to improve upon PID control. Newly added features are allowing the IACT parameters to be set less than the loop time, the DGTYPE parameter can now allow filtered or unfiltered derivative, a new Process Proportional Mode and certain PID parameters are now tunable. This session will show the different control responses to each of the new features and how they can be used in your system. A general overview of PID use cases and general tuning will also be covered.

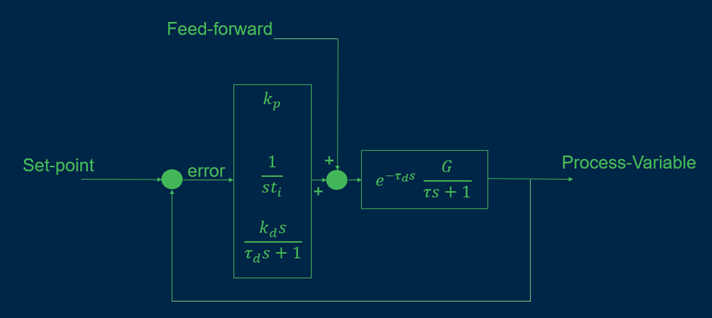

Matt opened by showing the block diagram of the proportional-integral-derivative (PID) function.

The Reset time cannot be less than the task loop time for normal PID operations. In the Ovation DCS, the Integral Action function, Allow < LOOP TIME, enables the Reset time to be less than the loop time. This capability allows for larger corrections in the integral term.

A new Proportional Action term enables the proportional term to respond to the process variable (PV) instead of the error, so it does not respond to setpoint changes that can cause overshoots.

With just proportional control, proportional gain reduces steady-state error, but it is non-zero, provides a fast closed-loop response, improves robustness, and provides stability for any positive value. Large gains can destabilize the loop and cause oscillations and overshoot.

With PI control, decreasing integral reset time causes instability due to the system delay, but it drives the steady-state error to zero.

PID control improves transient response due to derivatives’ predictive effect but is susceptible to noise. The derivative term amplifies noise, so it is a good idea to characterize the measurement noise and use the filter.

For PID control, the Proportional term should be decreased with more plant delay times. The Reset time should be increased with increasing plant delay times. The Derivative term may be increased with increased plant delay time but can have a destabilizing potential if not filtered properly.

Matt showed some of the math behind selecting your P, I, and D parameter values based on the measured responses in the process. Lambda tuning is a common method, which we discussed in several earlier posts.

Process Automation Hall of Fame member Greg Shinskey developed deadtime compensation, which compensates the integrator. There is no need to model parameters like the Smith-Predictor algorithm. Processes with a time lag in the load path greater than the delay in the control loop are not regulated by model matching, either. The robustness is affected by variations in gain and deadtime.

Another PID feature is a Transport Delay algorithm for a model deadtime greater than 8. The Advanced Process Control (APC) Toolkit includes a DMC block with six setpoints and six process variables, five disturbance variables, five control output variables, and a 45-sample step response for modeling. It also has a 2×2 and 3×3 model predictive control (MPC) block.

Visit the Ovation Engineering Station and Tools page on Emerson.com for more on the Developer Studio software to optimize your control logic and strategies.