Emerson’s Pawel Czoczys and Frat Kanat presented Streamline Tank Operations with “Sensor in a Cloud” Innovative Solution at the 2024 Emerson Exchange Conference in Düsseldorf, Germany. Here is their session abstract:

In the era of efficiency and sustainability, engineers and managers are looking for new technologies to improve operations sustainability, reduce operational costs, and enhance customer service level. In this session, participants will be introduced to the latest technological breakthroughs of the “sensor in a cloud”. This solution enables industries to streamline tank operations, optimize asset usage, and boost overall productivity. Covering everything from real-time data analytics to predictive maintenance, the session provides a comprehensive overview of the state-of-the-art tools transforming the field of tank management. Come aboard as we explore the advantages, obstacles, and future potentials of remote tank monitoring, providing insights into a connected future where tanks evolve from mere containers to intelligent assets propelling operational excellence.

Pawel opened by explaining the value of remote insight. From an asset management perspective, route optimization, asset usage planning, and maximum asset utilization are possible. From a supply chain perspective, production planning, automated ordering, and supply-controlled stock activities are possible. From a customer satisfaction perspective, quality control, improved service levels, and expedited delivery avoidance are possible.

Boundless Automation frees up data to enable the power of analytic software to drive world-class performance. Connecting isolated data to cloud-based applications enables manufacturers and producers to manage their operations more safely and efficiently.

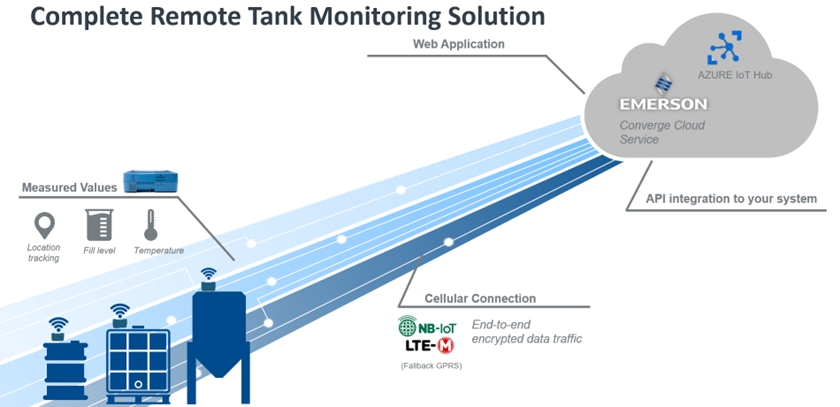

The Rosemount 408 Remote Tank Monitoring solution is a complete remote tank monitoring solution. Fill levels, temperatures, and location tracking information are transmitted through a cellular connection to integrate with the AZURE IoT hub or the Converge Cloud Service and made available for web-based applications.

Here are some specifications for the Rosemount 408 at a glance.

- Connectivity: LTE-M/NB-IoT (with GPRS fallback) Used to store chemicals of different types at end customer sites safely, for example, industrial laundry services where they are used for dosing into the washing machines Sensors: Non-contacting radar, ambient temperature, GPS

- Battery life: up to 3 years

- Mounting options: self-adhesive mounting plate, 1,5” threaded

- Temperature: -200C…+600C

- Height: 50 mm, including mounting plate

- Accuracy: +/-10 mm

- Range: 10 m level

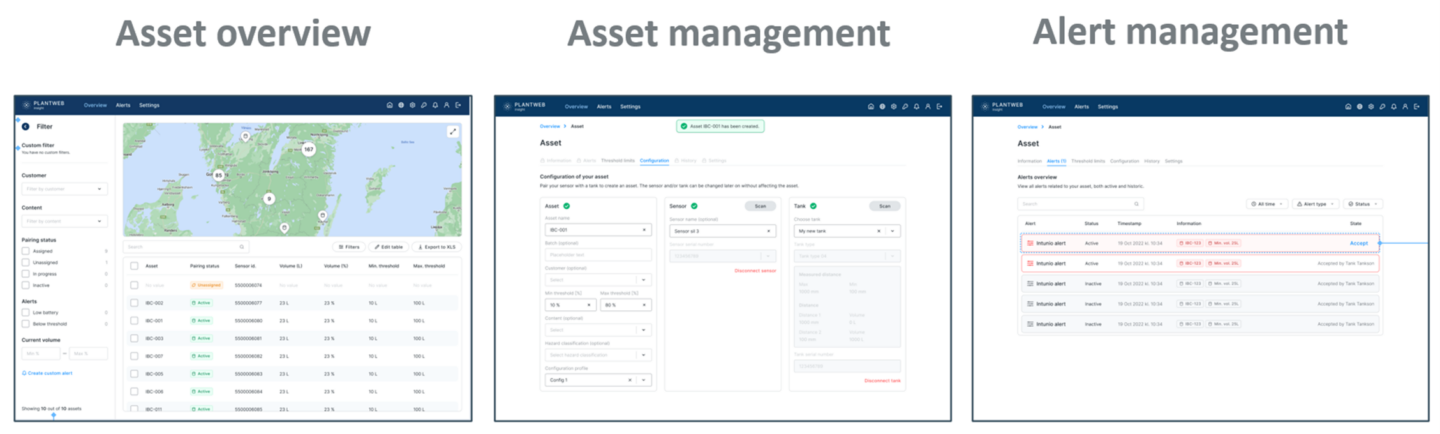

The Converge Cloud Tank App enables quick asset overviews, asset management, and alert management views of sensor data. The Converge Cloud Service refers to the cloud-native platform that will host the Remote Tank Monitoring applications.

Here are a few application examples showing how the Rosemount 408 and Converge Cloud Service can be applied.

- Chemical Injection at Well Pads. Anti-corrosion media is essential to ensure the longevity and efficiency of the oil wells. As production goes up and down, so does the consumption of the chemical.

- Chemical Storage & Dosing at End-User site. Used to safely store chemicals of different types at end customer sites, for example, industrial laundry services where they are used for dosing into the washing machines.

- Waste Oil Collection. Typically, it involves manual operations to measure the volume of waste oil. Companies have to monitor their tanks, plan collection routes, and optimize their operations.

With this remote tank monitoring solution, global coverage with encrypted cellular connectivity and information access are available from anywhere at any time. This enables improved and optimized route planning and reduces the CO2 footprint and logistical support costs.

Visit the Rosemount Remote Tank Monitoring System section on Emerson.com for more information on this innovative solution to drive improved operational performance.