At the Emerson Exchange EMEA 2024 in Düsseldorf, Dirk van Baelen, area sales manager at Emerson, described safety and efficiency improvements made by ITC Rubis at its tank terminal in Antwerp, Belgium.

ITC Rubis operates storage and transhipment of liquid chemicals, liquefied gas and petroleum products at the port of Antwerp.

ITC Rubis stores and handles flammable and toxic chemical liquids and liquefied gases, which makes safety a key issue for people and the environment. The company began operating in 2008 and currently has a total storage capacity of around 266,000 m³, with loading and unloading facilities for ships and trains. Storage tanks need safety systems, especially large tanks used to store flammable gases and liquids. Equipment used within safety instrumented systems must be regularly inspected and documented to fulfil safety and governmental requirements.

Overfill prevention systems (OPS) consist of a safety instrumented function (SIF) with three main parts – the sensor (level), logic solver and final control element (actuator and valve). The safety loop must be tested at regular intervals to make sure it works correctly. This is called a proof-test. A comprehensive proof-test of a SIF includes all parts of the SIF in the same proof-test. Operators may also perform a combination of partial proof-tests covering all parts in total.

A comprehensive proof-test returns the probability of failure on demand (PFD) average back to, or close to, the SIF original targeted level. PFD equals the risk of a SIF failing to perform the intended function. The PFD increases as time passes after commissioning. Proof-testing the SIS for hidden faults lets you know the SIS loop is free of errors, `resets’ the PFD to a lower value after it has increased over time, and ensures the SIS still provides the risk reduction it was designed to do.

When the tank OPS at ITC Rubis needed to be upgraded, the company approached Emerson to provide a solution that would be easier to use and test. The existing installation incorporated a radar sensor for level measurement and a vibrating fork assembly for overfill prevention. The new solution needed to solve several issues related to proof-testing. Firstly, ITC Rubis wanted to remove the need for workers to climb to the top of a tank to perform the tests. A comprehensive proof-test requires dismantling the tuning fork on top of the tank and activating the tuning fork in a cup of liquid. With tank heights of up to 30 meters, this exposed workers to an immediate hazard. ITC Rubis also wanted to eliminate the risk to workers from exposure to chemicals when opening the tanks, as well as any environmental impact due to emissions. It also wanted to stop exposing the stored products to oxygen and moisture, which can impact quality. The existing proof-testing regime was very time-consuming. There are a total of 76 tanks at the facility and it would take two people a total of 19 days (38 combined worker days) to perform tests on all devices.

A Rosemount™ 5900S 2-in-1 radar gauge from Emerson was chosen to replace the existing equipment. The 5900S contains two independent radar gauges in a single housing, with one used for tank gauging and the other for the OPS. The solution offers significant benefits in terms of proof-testing.

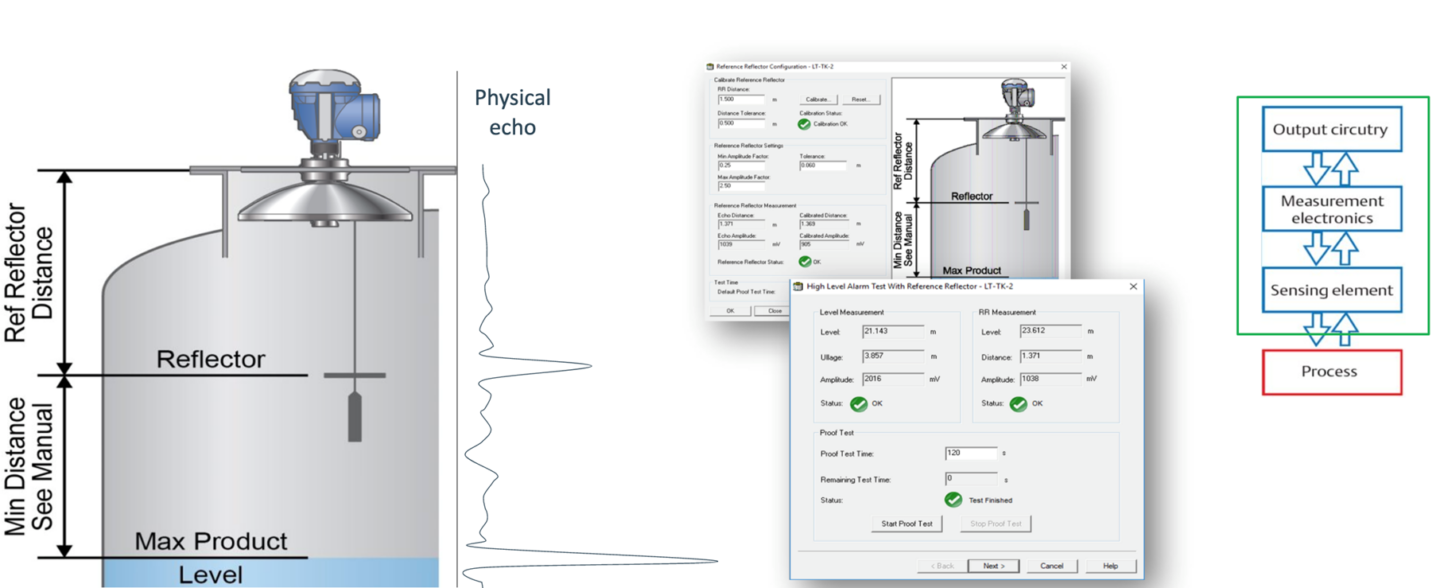

A comprehensive proof-test requires the tank to be filled to its safety limit. This is often impractical, time-consuming and creates its own safety risks. Performing a comprehensive test often affects tank operations and can cause costly downtime, making it expensive and difficult to perform. As previously mentioned, an alternative method is to use a combination of partial proof-tests. Here the level measurement (measurement electronics, sensor element) and output (output circuitry) of the 5900S are tested. To initiate the test, instead of filling the tank, the 5900S uses a high-level alarm verification test physical reference reflector in the tank. The entire test is managed remotely using the Proof Test Manager function within Emerson’s Rosemount TankMaster Inventory Management Software.

The Rosemount 5900S utilizes a high-level alarm verification test physical reference reflector.

The benefits ITC Rubis has realized from the Emerson solution are impressive. The safety of workers has increased as nobody must work at height and there is no need to break the tank seal, thereby eliminating exposure to chemicals. Emissions, as a result of opening the tanks, have been eliminated, as has potential product contamination. But the most impressive benefit is the amount of time saved. All 76 tanks can be inspected and documented within a day. That means 37 working days are saved, freeing up engineers to perform other important tasks.